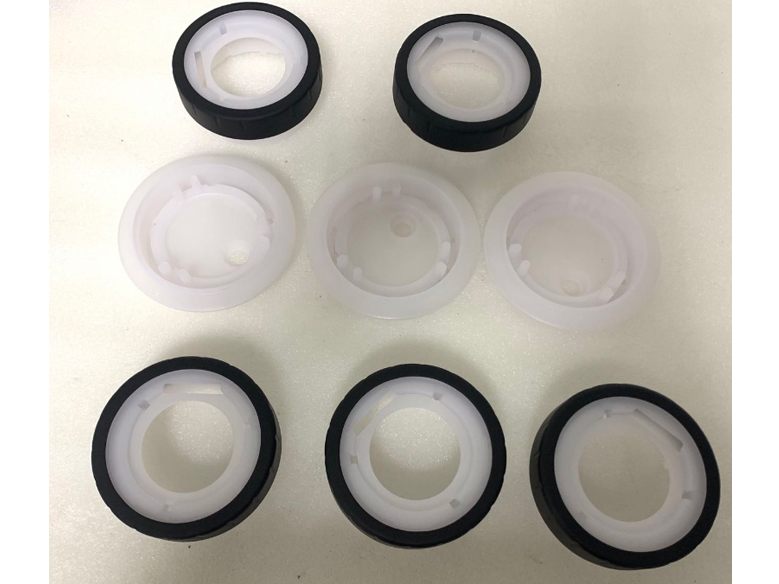

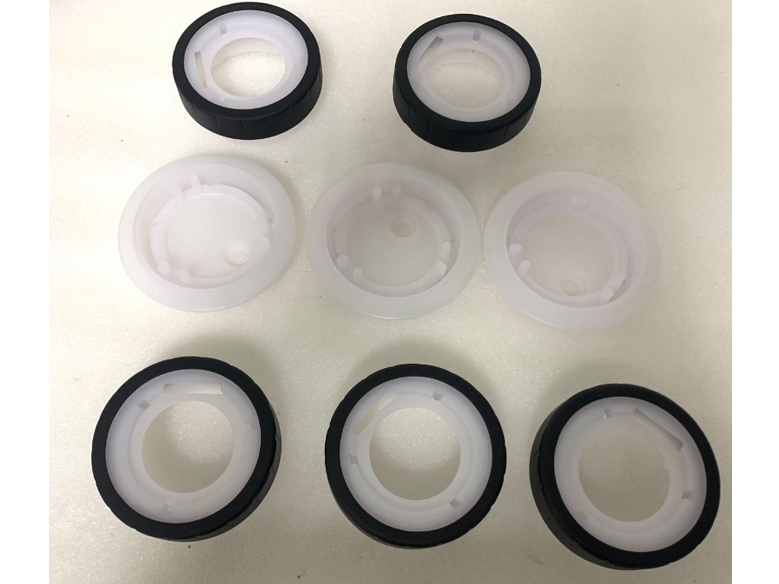

Vacuum Casting Plastic

High vacuum die casting process: free mold opening, low production cost, forming speed, high processing accuracy, support small batch customization and other characteristics, which can greatly reduce the product research and development costs and risks, but also accelerate the development progress.

Vacuum Pressure Casting Material Properties

Proto Mold can help you to make the cost cheaper with fast lead time in the short run small batches production. We have the 15 years experienced engineer to do the silicone mold. Vacuum casting plastic method is one of the best rapid prototype way to do it .

Shortcomings of PP

low dimensional accuracy, insufficient rigidity, poor weather resistance, it has a shrinkage phenomenon, moulding, easy aging, brittle, easy deformation.

Vacuum Pressure Casting Materials Info

1

Composite ABS material HEI-CAST 8150 is a new type of casting material with good physical properties, fast curing speed, high dimensional accuracy of finished products and sufficient practical strength. It can be used to confirm the shape and strength of injection molded parts, and also can be used for small batch production of final products.

2

ABS material HEI-CAST 8150, DPI860, PX5118 Similar to PC material, PX520, PX527; Rapid prototyping environmental protection material UP590; PP/PE material PX100,PX215; High

temperature resistant castables PX223 and 6160.

3

PP has the best heat resistance, thermal deformation temperature of 80-100℃, can be boiled in boiling water. PP has good stress cracking resistance and high bending fatigue life, commonly known as "100 fold adhesive". The comprehensive performance of PP is better than PE material. PP products of light weight, good toughness, good chemical resistance.

If you want to know more kinds of vacuum casting plastic parts, please contact us.

As a rapid cnc prototyping manufacturer, we will do our best to meet all the needs of customers.

Other supplier products

|

|

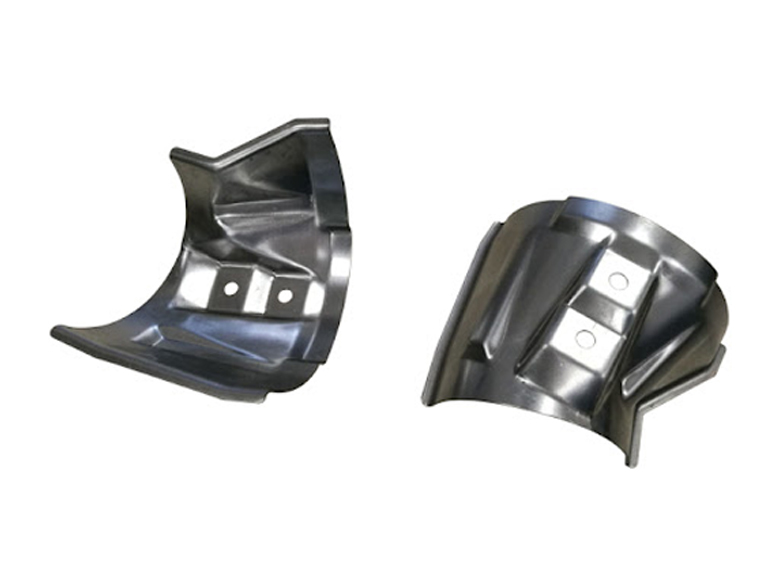

Stamped Sheet Metal Parts |

Proto-mold purchased advanced large laser cutting machine 3 sets, Amada precision CNC bending machine 15 sets, heavy oil pressing machine 3 sets an... |

|

|

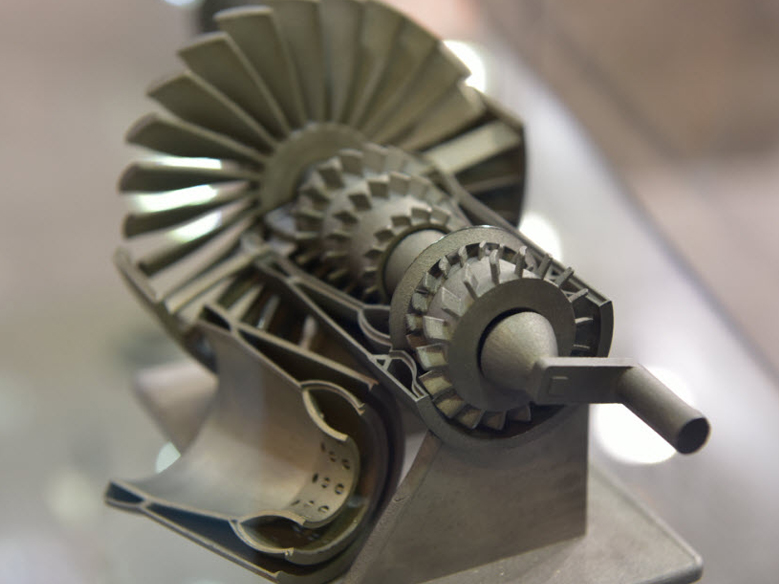

SLA Plastic 3D Printing |

SLA printingis focused on the surface of a light cured material, which is solidified from point to line and line to surface. SLA printing of SLA 3d... |

|

|

China Sheet Metal Fabrication |

China custom sheet metal fabrication servicesis a comprehensive cold working process for custom sheet metal fabricationcompany to produce sheet met... |

|

|

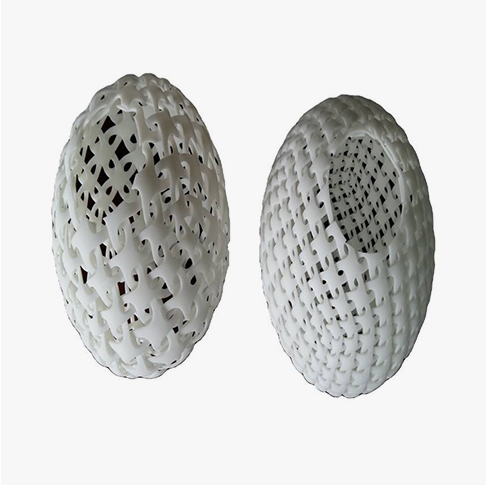

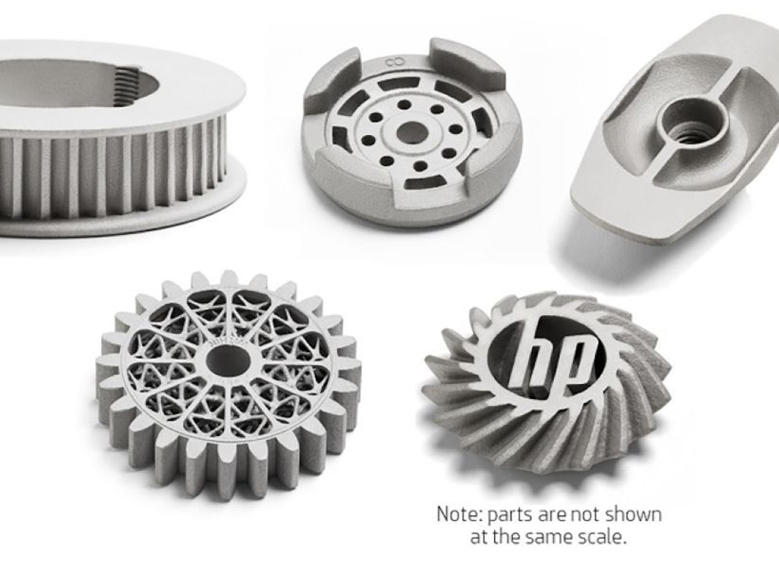

SLS Nylon Printing |

3D printed nylon parts can be used for product verification or directly used as functional products. The product is 3d prototype printing with ligh... |

|

|

Silicone Prototyping |

Soft Rubber rapid prototype, Hardness is generally between shore A 30~90 degrees, because soft rubber plastic prototype has flexibility, it is wide... |

All supplier products

Same products