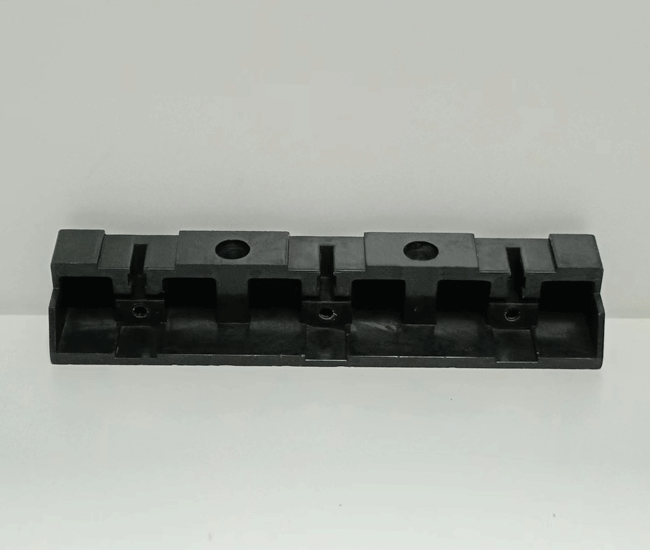

UNSCREWING MOLDS

UNSCREWING MOLDS

Unscrewing moldis a type of mold used in injection molding, primarily for producing threaded parts or components with screw-like features. It allows for the ejection of the molded part from the mold without damaging any threads or intricate features that would otherwise be challenging to release.

Related:Unscrewing Mold 101: Guide to Working, Importance, and Types

Here are some key points about unscrewing molds:

Functionality: Unscrewing molds are designed to rotate or unscrew core sections of the mold after the injection process. This rotation helps in releasing the molded part from the threads or undercuts inside the mold cavity.

Applications: They are commonly used for producing parts such as caps, closures, bottle threads, and any component requiring internal or external threads.

Mechanism: The mold typically includes threaded cores or components that rotate within the mold cavity. This rotation is powered by hydraulic or mechanical actions, synchronized with the molding machine’s operation.

Complexity: Compared to standard molds, unscrewing molds are more complex due to their moving parts and require precise synchronization and control during the molding process.

Advantages: They enable the production of parts with intricate threads or undercuts that would be difficult or impossible to release using conventional molds. This capability enhances design flexibility and allows for the production of more complex parts.

Considerations: Unscrewing molds require careful design and maintenance to ensure proper operation and longevity. The synchronization of mold actions with the molding machine is critical for consistent part quality and production efficiency.

If you have specific questions or need further details about unscrewing molds for a particular application, feel free to ask!

Send product request

Other supplier products

| precision injection molding | precision injection molding Precision injection moldingis a method demanding unparalleled accuracy in shaping plastic components. Unlike mass prod... | |

| Two-Shot Injection Molds | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Injection molding are numerous and significant. This cut... | |

| Thermoset Molding | Thermoset Molding Key Aspects of Thermoset Molding Materials: Thermosetting Polymers:These include epoxies, phenolics, polyesters, and silicones... | |

| UNSCREWING MOLDS | UNSCREWING MOLDS Unscrewing moldis a type of mold used in injection molding, primarily for producing threaded parts or components with screw-like ... | |

| Custom Plastic Molds molding | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile parts and product production methods. With a wealth of... |

Same products

| Thermoset Molding | Seller: WIT MOLD LIMITED | Thermoset Molding Key Aspects of Thermoset Molding Materials: Thermosetting Polymers:These inc... | |

| UNSCREWING MOLDS | Seller: WIT MOLD LIMITED | UNSCREWING MOLDS Unscrewing moldis a type of mold used in injection molding, primarily for produ... | |

| dsa anode | Seller: mmo ribbon anode | dsa anode DSA Anode , also known as dimensionally stable anodes, are titanium or niobium su... | |

| mmo electrode | Seller: mmo ribbon anode | mmo electrode MMO Electrode is the process of using electricity to break down water into hy... | |

| anode for printed circuit board | Seller: mmo ribbon anode | anode for printed circuit board Acid electrolytic copper plating is an important step in t... |