Automotive Part

As the foundation of the automotive industry, injection molding automotive parts are necessary factors to support the sustainable and healthy development of automotive mold manufacturers.

In particular, the current independent development and innovation in the automotive parts moldindustry that is being carried out vigorously and in full swing require a strong component system in automotive mold technology co ltd. Vehicle independent brands and technological innovation require automotive injection mold parts and components as the foundation, and independent innovation of parts and components has a strong driving force for the development of the vehicle injection molding automotive parts industry.

Features of Automotive Injection Mold

Here are three major features of using automotive injection molding for manufacturing injection moulding car parts.

Detailed Features

The automotive plastic injection molding is subjected to extremely high pressure. Therefore, the plastic is pressed harder against the automotive parts mold. This complex and intricate shapes of plastic injection molding automotive parts can easily be designed.

High Efficiency

Once the automotive parts molds have been manufactured to the customer’s specifications, it is very quick to the actual automotive precision plastic injection moulding. The high production output rate makes plastic injection molding automotive parts more cost-effective and efficient.

Enhanced Strength

In automotive plastic injection molding, it is possible to use fillers in the injection molds. This filler reduces the density of the plastic which will enhance strength.

How does Automotive Injection Mold Work?

Automotive injection mold is to first add plastic to the mold, and then the automotive parts mold is continuously rotated along two vertical axes and heated. Under the action of gravity and thermal energy, the plastic in the injection moulding automotive partsmold is uniformly coated and melted, and adhered to the entire cavity of the mold. On the surface, it is formed into the required shape of injection molding automotive parts and is made by cooling and shaping.

The Specification of injection molding automotive parts

|

Part material |

ABS + PC |

|

Mould Cavity |

1 |

|

Mould steel |

|

|

Mould steel |

A, B, C, plate P20, others 1.1730 |

|

Tooling life |

100W |

|

Mould standard |

HASCO |

|

Exporting country |

Germany |

|

Leadtime |

5 weeks |

|

Customer satisfaction with mould quality |

95% |

|

FAI pass rate |

99% |

|

Customer satisfaction with project cooperation service |

98% |

GM-TECH is an experienced plastic injection molding factory, we provide plastic parts injection molding, injection molded partsand etc. Contact us to know more about mold technology.

Send product request

Other supplier products

| Product Development | Product Development Our company is not engaged in product development, but we are willing to assist customers to design product appearance and pro... | |

| Injection Moulding Products | GM-TECH, injection moulding manufacturers,has been manufacturing tools for injection molding of plastics for various industries for more than 10 ye... | |

| Electronics Product Part | With the fast growth in the electronic industry, the demand for injection molding electronics is much higher. The injection molding electronics can... | |

| Electronics Product Mould | Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding products. The electronics ... | |

| Automotive Part | Automotive Part As the foundation of the automotive industry, injection moulding automotive partsare necessary factors to support the sustainabl... |

Same products

| ALP_606 | Seller: Leetop Technology (Shenzhen) Co., Ltd. | Leetop_ALP_606 is an embedded artificial intelligencecomputer based on NVIDIA Orin NX core board,... | |

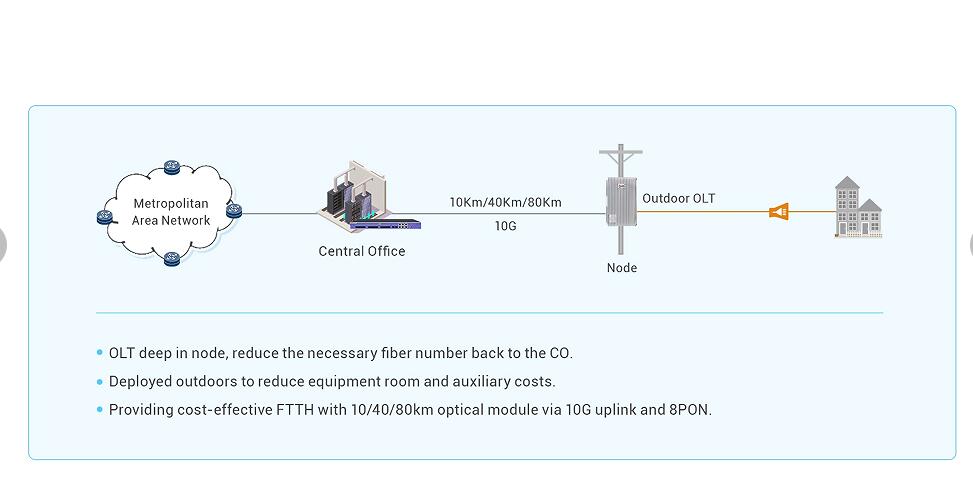

| OUTDOOR OLT | Seller: Shenzhen C-Data Technology Co., Ltd. | Deploying outdoor cabinet OLTdownward, closer to users 8 PON PORTS GPON OLT FD1608Y 2*10G SFP+... | |

| Optical Transport Networking | Seller: Shenzhen C-Data Technology Co., Ltd. | C-Data Optical Transmission Network (OTN products) products are designed to build professional ne... | |

| Hybrid Fiber-Coaxial | Seller: Shenzhen C-Data Technology Co., Ltd. | C-Data Hybrid Fibre Coaxial HFCproducts provide high-quality image, digital or signal transmissio... | |

| ONU | Seller: Shenzhen C-Data Technology Co., Ltd. | C-Data XPON ONU Enjoy the Rapid Internet Large Bandwidth | High Reliability | Easy Management... |