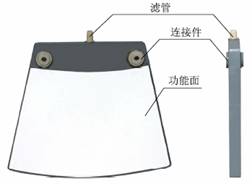

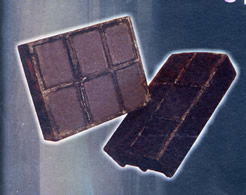

Ceramic filter plate

Manufactured by our patented production techniques, the filter plate consists of two cavity-structures that are made of corundum-based materials. The process include raw-material classification, cleaning & selecting, mixing, high-accuracy molding through die stamping, stage-wise high-temperature roasting, repetitious painting of function layer, cleaning & choosing, finalizing gluing, performance testing, packing and placing in storehouse. Repetitious roasting and layer-after-layer painting are adopted.Manufactured by our patented production techniques, the filter plate consists of two cavity-structures that are made of corundum-based materials. The process include raw-material classification, cleaning & selecting, mixing, high-accuracy molding through die stamping, stage-wise high-temperature roasting, repetitious painting of function layer, cleaning & choosing, finalizing gluing, performance testing, packing and placing in storehouse. Repetitious roasting and layer-after-layer painting are adopted. Thus, the arrangement of pores (interior is big, exterior is small) is clear, the resistance at function restoring process is small, the cleaning of filtering plate is easy, and the surface layer is of high strength and wear-resistant. The two pieces of cavity-structures are glued together using imported epoxy glue. The gluing is of high strength and is corrosion-resistant & wear-resistant. Features and Applications: The ceramic filtering plates produced by our plant have been proved as successful in many beneficiation plants treating ores of copper, lead, zinc, iron, silver, sulfur, gold etc. The filtering plates are of high strength, easy to be cleaned for restoring of function. The maximum pressure for reverse cleaning reaches 0.3MPa, the level that increases the performance of back cleaning & combined cleaning and raises remarkably the operation indexes of the filter. The service life of the filter exceeds 1 year that saves the investment & operational cost of customer. 1. High strength, abrasion and corrosion resistant and long service life. 2. Size of micropore is small(normally with diameter of 1.0um), strong capillary effect. 3. Low power and energy consumption as filtrates drawn into micropore automatically. 4. High filtration pressure drop(vacuum degree can reach-0.098Mpa) and low moisture of filter cake. 5. Filtrate is clear and transparent with low suspended substances(21ppm), Filtrates can be used as industrial circulation water.

Send product request

Other supplier products

| Magnetic Liner | The magnetic liner is composed of ferrite and modified nonmagnetic steel and is arranged in an alternative order of N and S poles of the magnetic s... | |

| Vacuum Ceramic Disc Filter | Vacuum Ceramic Disc Filter is new type solid-liquid separation equipment featuring high-efficiency and energy-saving. Shengnuo Group successfully d... | |

| Ceramic filter plate | Manufactured by our patented production techniques, the filter plate consists of two cavity-structures that are made of corundum-based materials. T... |