Automotive Mold

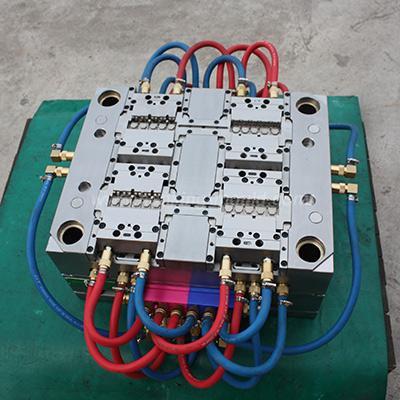

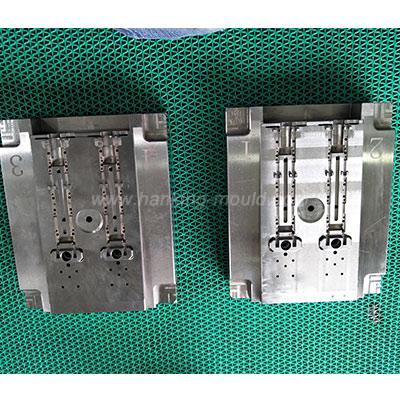

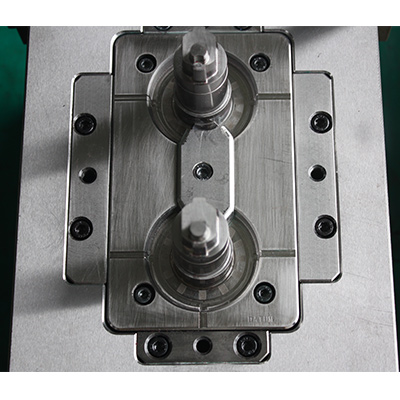

Plastic Auto Parts Sensor Mould

HanKing Mould produce all different kind fuse and connector for international OEM company, we have a lot of experience to short the project development time.

HanKing Mouldserves for globally Automotive & Vehicle products customers, more than 10 years of experience enabling the HanKing team to provide customers the fast development time and stable quality to ensure the new project running well. Shenzhen Hankingengineer will analysis the filling to obtain the best gate position the best flowing regime, and design the best cooling channel to ensure the minimum wrapping deformation and we have a very good injection operator to help set the best injection parameter to avoid any development time waste and improving the molding parameter reliability.

HanKing Mould is very experienced in small and medium-sized automotive plastic mould, in the past years, the types of products we involved were included fuse and fuse box, connector, switch, relay, sensors, actuators, terminal, valve, handle and other body accessories.

In the development of the automotive industry, the proportion of plastic parts in automotive parts is very large, and the demand for plastic parts is increasing day by day because plastics have the advantages of beautiful appearance, lightweight and easy processing. Most plastics have a specific gravity of 0.9 to 1.6, and the proportion of glass fiber reinforced composites will not exceed 2.0, while A3 steel is 7.6, brass is 8.4, and aluminum is 2.7. The use of plastic can reduce the weight of parts by about 40%, and the cost can be greatly reduced, which makes plastic the preferred material for automotive light-weighting. Plastic is easy to molding parts with complex shapes. According to the plastic composition of the plastic, by adding different fillers, plasticizers and hardeners to produce the desired properties of the plastic, changing the mechanical strength and processing properties of the material to meet the requirements of different parts of the car. The plastic consumption of each auto part accounts for 20% of the total vehicle materials and may reach 35% in the future. When the auto company develops a new car, it needs to use hundreds of sets of plastic injection molds, which requires the quality assurance of plastic parts in production, and the quality of plastic parts is determined by the mold.

Which parts of the car are commonly used in plastic?

Bumper, the instrument panel accessories, inlet grille, fender, radiator grille, trim panel, engine parts, Water tank accessories, air conditioning accessories, air filter accessories, various kettles, seat accessories, floor panel accessories, roof panel accessories, bar accessories, steering wheel accessories, door trims, rearview mirrors and various fastener, front and rear lamp, etc.

Send product request

Other supplier products

| Sewing Machine Frame Mould | Sewing Machine Frame Mould Large plastic frame plastic injection sewing molds, suited for oversize embroidery projects. Mould Name: Embroidery ... | |

| Gear Mould | Gear Mold Design Customs Plastic Gear Mould Name:Custom Plastic Gear Mould Part Material:POM Product Size: Product Description: Plastic Motor Gear ... | |

| Insert Molding Technologies for Automotive Industry | Insert Molding Technologiesfor Automotive Industry Mould Type: Automotive Sensor Plastic Injection Mould Production Material: Nylon PA66 No ... | |

| Family Mould | HanKing Mould Enginering Ltd. started the business in the year of 1996 as one of the chinese plastic injection molding companiesin the line of mold... | |

| Insert Molding | What is insert hanking moulding? Insert molding solutionsof hanking refers to a hanking mould technologyprocess in which an integrated product is m... |

Same products

| ARM Cortex-A53 controller support Linux Ubuntu with 4DI to Pulse countin/Data control for smart factory | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... | |

| ARM 2*Cortex-A53 computer with 2DI+2DO support Ubuntu for energy storage | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... | |

| T507-H processor Controller 8GB eMMC 1GB DDR4 + 4RS485 support Linux for edge computing | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... | |

| ARM Computer 8GB eMMC 1GB DDR4+16GPIO support Docker for Industrial IoT. | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... | |

| 1.4GHz Computer with 4*PGIO support Ubuntu for Energy Storage ARM Computer. | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... |