sealing material electrical insulation silicon glue sealant corrosion-proof

sealing material electrical insulation silicon glue sealant corrosion-proof

Description

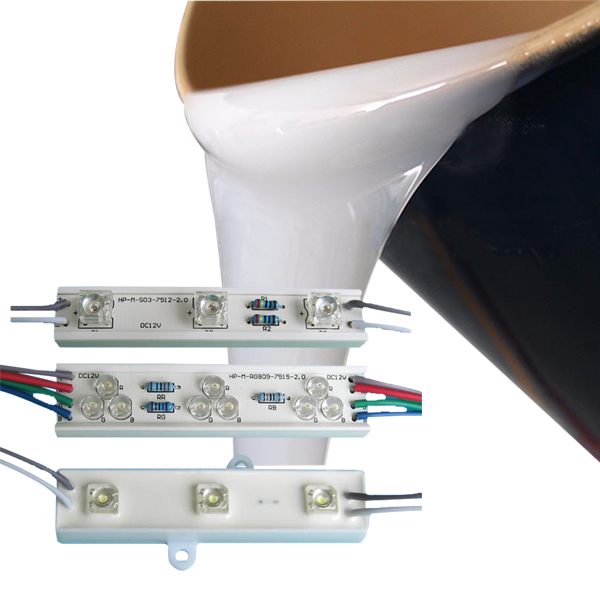

Two-component silicone,platinum-curing/ addition-cure type, flowable, vulcanizes at room temperatureor heated temperature.

Can be used for a long time in the temperature range of - 65 ° C - 200 ° C and keep its soft and elastic properties.

Application

Used for potting, encapsulating, sealing and bonding, widely used in electronic products, electricity, power supply, automotive ect. For example, used for potting of electronic components, power module and control module and controllers, junction box, solar cell assembly etc..

Can reduce stress and withstand high and low temperature impact. For the high power control module, thermal conductive silicone is used to achieve the function of heat dissipation, or outdoor protection for electronics such as LED screen.

Improve the insulation level ofelectronics, improve heat dissipation, and avoid the risk ofelectronicsoverheating and burning in a short time.

Features& Advantages

²Excellent flow leveling

²Fire proof, flame retardant

²Waterproof

²Insulation

²Moisture proof

²Anti-fouling

²Anti-corrosion

²Quake-proof/ withstand vibration

²Thermal conductive

²Ozone resistance

²Weather aging resistance

²Low shrinkage

²Can be operated in all kinds of harsh environments without too much requirementfor the environment (Moisture, salt fog, dust, vibration, heat, deep sea, cold, etc.).

Typical propertiesINI-9025

|

PropertiesIndex |

Test Report |

|

|

Before Curing |

Appearance |

Black, white, red Fluid |

|

Viscosity(cps) |

2000±500 (Adjustable) |

|

|

Operating |

Mixing Ratio (By weight) |

1:1 |

|

Operating Time(25℃/min) |

20~30 (Adjustable) |

|

|

Curing time(hr,basically cured) |

1~2 (Adjustable) |

|

|

Curing time(hr, perfectly cured) |

12 |

|

|

After Curing |

Hardness (shore A) |

25±3 |

|

Thermalconductivity [W(m·K)] |

≥0.8 |

|

|

Dielectricstrength(kV/mm) |

≥25 |

|

|

Dielectricconstant(1.2MHz) |

3.0~3.3 |

|

|

Volume resistivity(Ω·cm) |

≥1.0×1016 |

|

|

Fireresistance |

UL94-V0 |

|

|

Density (g/cm) |

1.35 |

|

Notes: Above data are only reference values, actual data is floating and adjustable.

Operation instructions

1. Before use, first mix component A well, which can make the colloid fluidity better than that when it is used directly after it has been standing still for a long time;Then shake component B well to make the bonding component in component B more uniform.

2. When mixing, observe the weight ratio of component A: component B = 1:1.

3.It is a product cured at room temperature after pouring. After basic curing, it will enter the next process. It will take 12 hours for deep curing.

Package

5KG, 20KG, 25KG and 200KG per drum.

(There are metal drum and plastic drum for your choice for 5KG and 20KG)

Shelf life

Twelve(12) months when stored under dry and cool place by original package under 25℃.

WhyChooseus

1.Powerfulfactorywithaproductioncapacityof8000perday, we are the more than 10 years factory in China, with excellent and stable quality.

2.High-endresearchanddevelopment(freesample)

BeingaleadingliquidsiliconemanufacturerinChina,wehaveaprofessionalR&DteamandQCteam(12experts)andourproductisRoHS,MSDS,ISO,REACH,ULapproved,sothereisnoneedtoworryaboutthequality.

3,Efficientservice

Wecanprovidefreetrainingofsiliconetechniqueandfreesiliconesamples.wehaveaprofessionalsalesteamwhowillsolveyourproblemspatiently.Besides,withefficientlogisticsdistributionsystem,youcouldgetyougoodsearlier.Last,goodaftersalesservice,webuildlongtermcooperationrelationship,oncethereisqualityproblem,wecouldsolverightaway.Moreimportantly,returnandexchangeareacceptedwhilequalityproblemsoccurred.

Free sample is available for your try. Welcome to ask~

We can provide the free sample, more details about silicone rubber, pls contact Ms Lisa at:

Mobile/ Whatsapp/: +86 188 1670 2967

2967 or A108059

E-mail: lisasilicone(at)

Twitter/Facebook:lisasilicone

Send product request

Other supplier products

| Pad printing silicone rubber liquid raw material elastic material electronic | Pad printing silicone rubber liquid raw material elastic material electronic Description Two-component silicone, tin-curing, flowable, vulcanizes... | |

| clear platinum cure silicone rubber jewelry molding high quality free sample | clear platinum cure silicone rubber jewelry molding high quality free sample Description High transparency, two-component silicone,platinum-curin... | |

| skin safe medical silicone rubber sex doll dildo silicone breast bra silicon | skin safe medical silicone rubber sex doll dildo silicone breast bra silicon Description Two-component silicone,platinum-curing/ addition-cure t... | |

| life casting food grade silicone rubber soft sex doll two parts liquid silicone | life casting food grade silicone rubber soft sex doll two parts liquid silicone Description Two-component silicone,platinum-curing/ addition-cur... | |

| sealing material electrical insulation silicon glue sealant corrosion-proof | sealing material electrical insulation silicon glue sealant corrosion-proof Description Two-component silicone,platinum-curing/ addition-cure ty... |

Same products

| Trimellitic anhydride 97% | Seller: Yufeng International Group Co., Ltd | Trimellitic anhydrideis a 2-benzofuran compound having oxo groups at the 1- and 3-positions and a... | |

| Isobutyric Anhydride CAS 97-72-3 | Seller: Yufeng International Group Co., Ltd | Product Name: Isobutyric Anhydride CAS No.: 97-72-3 Purity: 99% Molecular Formula: C6H10O3 Mo... | |

| Isobutyric Acid CAS 79-31-2 | Seller: Yufeng International Group Co., Ltd | Product Name:ISOBUTYRIC ACID Synonyms: 2-Methylpropanoic acid 79-31-2 Isobutanoic acid 2-Met... | |

| 2-Amino-2-methyl-1-propanol(AMP)CAS:124-68-5 | Seller: Yufeng International Group Co., Ltd | AtYufeng, a trusted 2-Amino-2-methyl-1-propanol Factory & Supplier, we prioritize quality and... | |

| Dimethyl sulfoxide (DMSO) CAS: 67-68-5 | Seller: Yufeng International Group Co., Ltd | Yufengis one of the leading dimethyl sulfoxide suppliers and also a professional such manufacture... |