MAGNESIUM ALLOY POWDER

We supply AZ91D, AM60B magnesium alloy powder of various sizes. Magnesium alloy powder is suitable for the semi-solid machine (thixo) production and processing parts.

AZ91D MAGNESIUM ALLOY POWDER

AZ91D magnesium alloy powder is a type of powder made from the magnesium alloy AZ91D. This alloy is a popular choice in industries that require lightweight and strong materials, such as the aerospace and automotive industries. The AZ91D alloy consists of magnesium, aluminum, and zinc, and it has excellent mechanical properties, corrosion resistance, and good castability.

The powder form of this alloy is used in various applications, including 3D printing, metal injection molding, and thermal spray coatings. The powder can be processed in various shapes and sizes, depending on the requirements of the application

AM60B MAGNESIUM ALLOY POWDER

AM60B magnesium alloy powder is a type of powder made from the AM60B magnesium alloy. This alloy is composed of magnesium, aluminum, and manganese and is known for its high strength-to-weight ratio, good corrosion resistance, and excellent castability.

Due to its high strength-to-weight ratio, the AM60B alloy is commonly used in the automotive and aerospace industries, where weight reduction is critical for improving fuel efficiency and performance. Additionally, it is used in applications where a lightweight, strong, and corrosion-resistant material is required, such as in electronic devices, sporting equipment, and medical devices.

WHAT ARE THE DIFFERENCES BETWEEN AZ91D AND AM60B MAGNESIUM ALLOY POWDER

AZ91D and AM60B magnesium alloy powders have some differences in their composition and properties. Here are some of the main differences:

Composition:

AZ91D: magnesium, aluminum, zinc

AM60B: magnesium, aluminum, manganese

Mechanical properties:

AZ91D has a higher strength and hardness compared to AM60B.

AM60B has a higher elongation (ability to stretch without breaking) compared to AZ91D.

Corrosion resistance:

Both alloys have good corrosion resistance, but AZ91D has slightly better resistance to saltwater corrosion.

Castability:

Both alloys have good castability, but AZ91D is easier to cast compared to AM60B.

Applications:

AZ91D is commonly used in the automotive and aerospace industries, as well as in consumer electronics and sporting equipment.

AM60B is also used in the automotive and aerospace industries, as well as in medical devices and electronic components.

In summary, both magnesium alloys have their own strengths and weaknesses, and the choice between them will depend on the specific requirements of the application.

As a professional magnesium supplier, YiRui Metal can customize the size and chemical composition of our magnesium metal products according to our customer's requirements. For magnesium alloy price, contact us.

Other supplier products

|

|

MAGNESIUM & MAGNESIUM ALLOYS USED FOR IN INDUSTRY |

What Is Magnesium Used for in Industry?

The applications are mainly used in magnesium production, steel desulfurization, metal reduction, corros... |

|

|

IS MAGNESIUM A TRANSITION METAL? |

When it comes to chemistry, the periodic table is a fundamental tool for categorizing and understanding elements. One classification of elements on... |

|

|

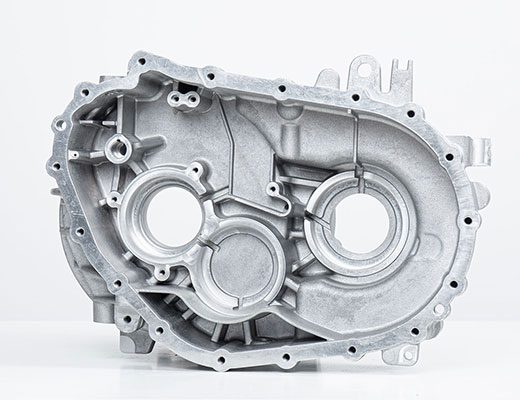

MAGNESIUM ALLOY DIE CASTING |

YiRui Metal can provide the service of magnesium alloy die casting, provide the related magnesium alloy parts according to the customer's requireme... |

|

|

MAGNESIUM ALLOY |

The bright future of the magnesium market benefits from the transformation and level-up of China's automobile industry, like 3C and other industrie... |

|

|

AM60B MAGNESIUM ALLOY |

AM60Bseries magnesium alloy is suitable for automotive parts and power tools, we got 6KG long term stock, 12KG and other specifications needs to be... |

All supplier products

Same products