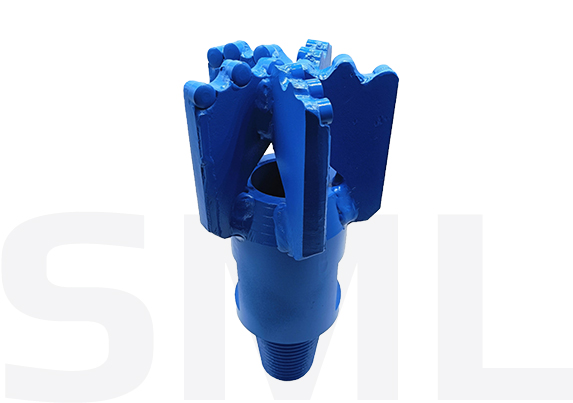

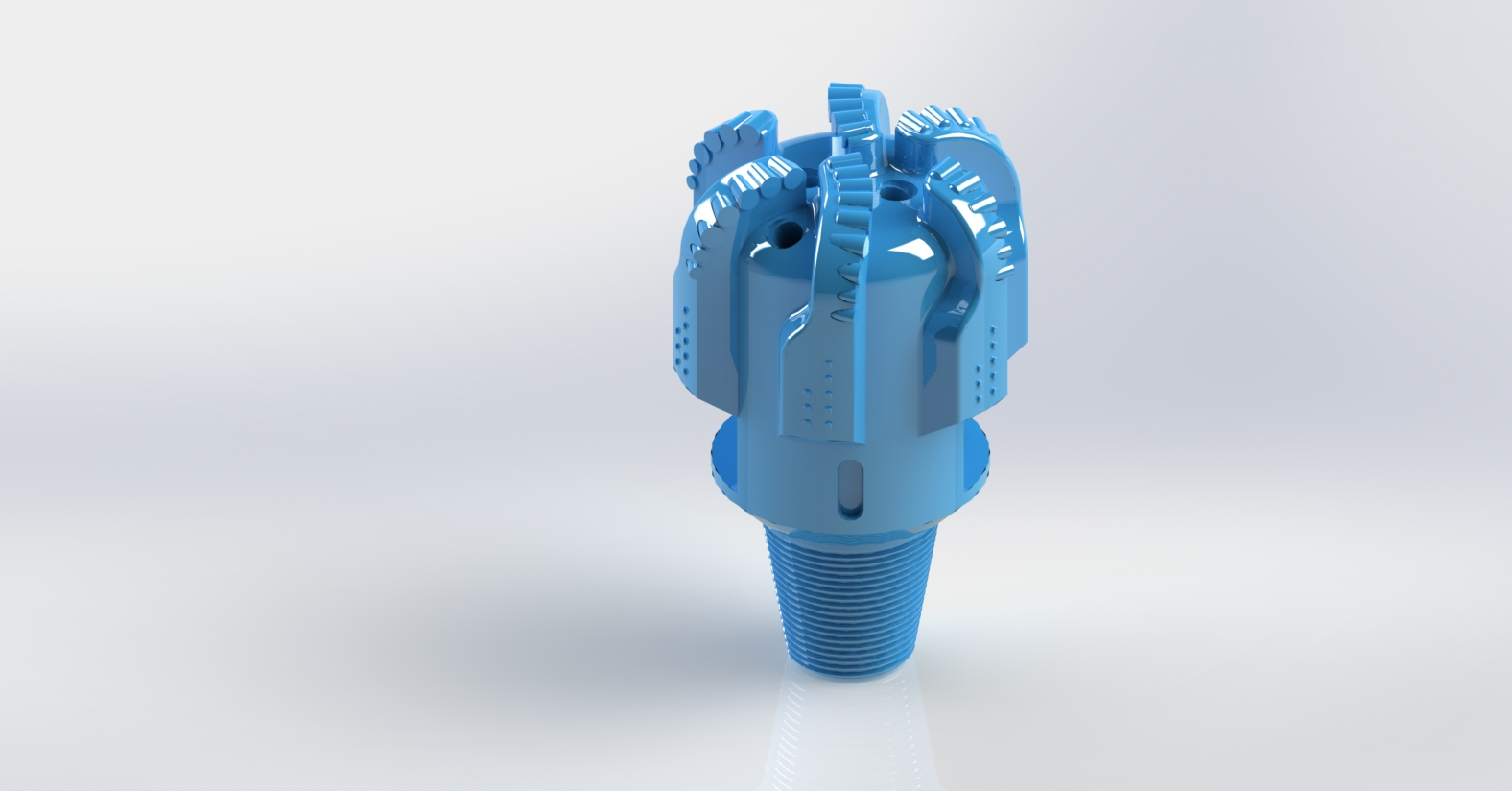

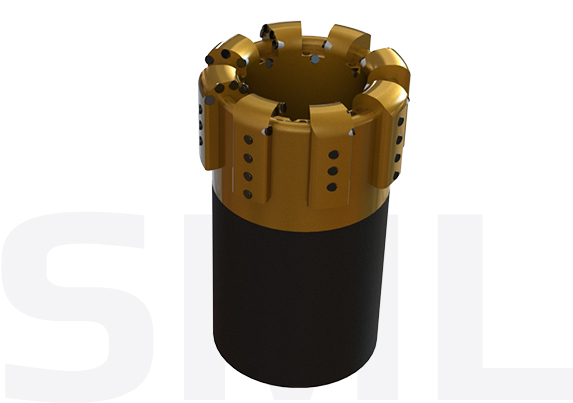

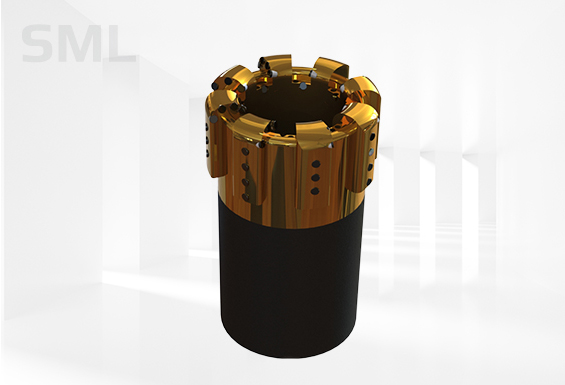

PDC DRAG BIT

The PDC drilling drag bit consists of four parts: the bit body, the scraper blade, the water divider cap and the nozzle. The drill body is the body of the scraper bit with welded scraper blade and water divider cap, which is made of medium carbon steel. The lower end is welded with scraper blade and water dividing cap, and the upper end is connected to the drill column with a wire fastener. The drag blade, also called the blade wing, is the main working part of the scraper bit.

PDC Drag bit are suitable for drilling in soft to soft soils and plastic and brittle formations such as mudstone, muddy sandstone, shale, etc. SML's Drag bits are generally produced in customized styles, mostly based on customer drawings and size requirements.

Features Of PDC Drag Bit

PDC Drag Bit are suitable for soft and cohesive formations. Scraper bits break rock by cutting. When a scraper bit works in a soft plastic formation, the cutting process is similar to that of a knife cutting soft metals. The blade eats into the formation under drilling pressure, while the rock in front of the cutting edge is continuously flowing plastically under torsional force, and the rock at the bottom of the well is stripped up in layers.

Advantages Of SML PDC Drag Bit

Professional customization: senior designers design corresponding drawings according to customer needs to meet customer demands.

Extra large water hole design is conducive to water intake and slag discharge, increasing drilling efficiency.

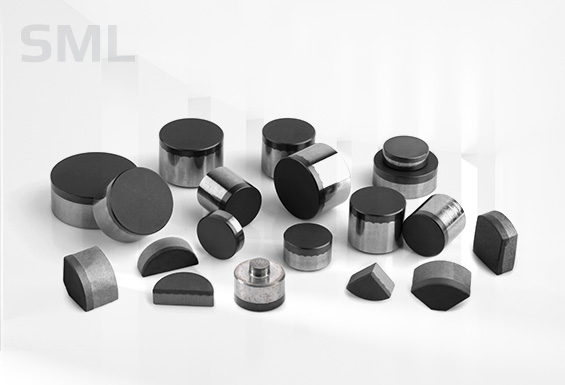

PDC Drag Bit adopts the principle of equal cutting volume to lay the teeth, which makes the bit wear more evenly and prolongs the bit life to the maximum;

The PDC Drag Bit adopts the hydraulic structure of blade wing combined with water eye and flow channel, so that the bit can be cleaned timely, avoiding the repeated breaking of rock chips and giving full play to the cutting efficiency of the bit.

In terms of manufacturing process, we have researched and developed medium frequency induction low temperature brazing technology and PDC drill bit mold forming technology to ensure the manufacturing quality of the drill bit.

Drag Bit has wide adaptability to the formation and can be used for drilling in soft to medium-hard (2-6.5 grade) non-abrasive formations.

If you are looking for a reliable drill bit factory, don't hesitate to contact us!

Other supplier products

|

|

PDC CORE BIT |

PDC core bits, also known as hollow bits, are tubular multi-toothed instruments embedded with carbide chips. Outfitted with carbide inserts, they e... |

|

|

5 Wings PDC Drag Bit |

Drag bits for water well drilling by using a polycrystalline diamond compact cutter, has high hardness and wear resistance, the drag bit blade betw... |

|

|

Matrix PDC Drill Bit |

PDC matrix bitis a kind of cutting bit that weld the diamond composite piece on the drill head body by brazing. PDC matrix bitis sintered with tung... |

|

|

Matrix PDC Drill Bit |

PDC matrix bit is a kind of cutting bit that weld the diamond composite piece on the drill head body by brazing. PDC matrix bit is sintered with tu... |

|

|

PDC BIT |

PDC bit Big blade design: The blades of all PDC drilling series are raised and increased. Using oversized crumb running design can more effectively... |

All supplier products

Same products