FUXI ® EPOXY PAINT

Liquid epoxy paintare the most important category of anti-corrosion coating products.

They are widely used in:

the hull of the ship, deck (including skid board and flight deck, etc.), ballast tanks and cargo tanks;

the superstructure of the oil platform, ground pipelines, buried pipelines and submarine pipelines, etc.;

the inner walls of pipes and storage tanks with media of drinking water, wine, food, etc.;

industrial floor;

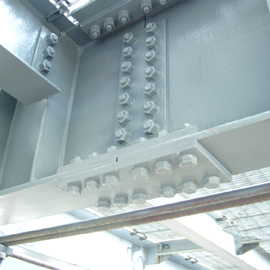

bridges and so on.

Normal atmospheric temperature curing epoxy paints are the most commonly used. They can be combined into anti-rust primers, high build coatings, novolac coatings, topcoats and glass flake coatings, which are used on steel and concrete surfaces.

Epoxy paints have very strong adhesion with substrates. The cured epoxy paint film has a very compact molecular structure. Its benzene ring and ether bond are stable, so it can be used in a chemical environment.

Types of FUXI ® Epoxy Paint

The Advantage of Epoxy Paint

Epoxy paints has strong and good adhesion to most substrates

Good physical and mechanical properties, such as hardness and flexibility.

Outstanding abrasion resistance, of which solvent-free epoxy paint is the best.

Excellent alkali resistance, excellent chemical resistance and solvent resistance. Amine curing coating is best

It is good to the temperature 120°C in a dry environment.

How to Apply Epoxy Paint

Step 1. Make sure the surface is clean

The first step is to ensure that the area to which the epoxy will be applied is clean. After ensuring that the surface is clean, use more paper towels or rags to dry it. Try to ensure that the wall is absolutely dry, as any moisture will affect the performance of the epoxy paint.

Step 2. Add epoxy

Next, you can start applying epoxy paint on the surface. In order to achieve the best results for your paint, please stir the contents of the bucket thoroughly before use, as this will help mix the various ingredients together and prevent bubbing. Apply the paint evenly, being careful not to leave air pockets or part of the brush in the paint. Stir the remaining paint in the tank from time to time, as this will ensure that the ingredients stay together when the paint is applied.

Step 3. Drying

After this is done, you will have to dry the paint for a few hours before deciding whether you need a second coat. You must make sure that no one touches the paint during the drying process. If you decide to add a second layer to completely cover the wall, you must ensure that the surface is completely dry before repainting. Leave it for about 24 hours to ensure complete drying.

Step 4. Finishing

Before completing the project, a layer of varnish must be applied to the surface. This will help increase the gloss of the epoxy coating and provide a proper seal for the wall. Before applying the varnish, you must wait again until the surface is completely dry. Use spray to ensure that the walls are covered with even paint

Epoxy Paint vs Acrylic Paint

Epoxy paint has a long service life

In terms of the service life of acrylic paint relative to epoxy resin, epoxy resin is bound to win! Epoxy resins are very difficult to cure, so they are more durable than acrylic paints. Painted epoxy pools can take 7 to 10 years (sometimes longer). Acrylic paint is not as durable as the latter. It needs to be repainted every 2 to 3 years to maintain the best condition.

Acrylic paint is easier to use

Acrylic paint can be used on almost any surface without any special measurement or mixing. Acrylic paint is also usually water-based, so it is easy to clean up. On the other hand, epoxy resin requires a mixture of catalyst and hardener. Epoxy resin can only be applied to other epoxy resins or bare, unpainted surfaces. The epoxy resin begins to cure as soon as it is mixed, so it must be used as soon as possible. Both types need to be prepared before use.

Epoxy paint is more cost-effective

In terms of cost, the cost of epoxy paint per square is much higher, which is an upfront investment. Acrylic paint is cheap and has a higher coverage per gallon. Because epoxy paint has a longer service life, the cost will become lower or even lower over time. You must also consider labor costs when using acrylic paint.

FAQS of Epoxy Paint

What is epoxy paint used for?What is epoxy paint used for?

Epoxy paints are the most important category of anti-corrosion coating products.

To mix with different hardeners, epoxy paint can be abrasion resistant, chemical resistant, solvent resistant, fire retardant, waterproof, and heat resistant.

Is epoxy paint waterproof?Is epoxy paint waterproof?

Why does epoxy paint lose its color fast outdoors?Why does epoxy paint lose its color fast outdoors?

There are ether bonds in the epoxy resin, and the resin molecules are easily degraded and broken under the sunlight and ultraviolet rays. That is why the epoxy coating film will lose gloss and get chalking when used on outdoor projects.

We are the paint supplier. we provide special coatings, bottom coat paint for boats, epoxy paint vs regular paint, china outdoor epoxy floor, wine tank coatings, micca pool paint, high build epoxy resin, modified epoxy paint, marine grade paintand etc. Want to know more, contact us.

Send product request

Other supplier products

| FUXI ® ZINC-RICH PAINT | Zinc powder is the most important electrochemical antirust pigment. A primer made with a large amount of zinc powder is called a zinc-rich primer. ... | |

| Epoxy Enamel | Under FUXI® brand, Jinhai Special China Coatingshas developed our own formulation system, including epoxy, phenolic, alkyd, acrylic, silicone, ... | |

| Exterior Wall Paint | Weather Resistant Acrylic Exterior Latex Wall Paint is a premium quality, water based 100% acrylic emulsion paint, with excellent UV resistance and... | |

| CALCULATION OF CONSTRUCTION AREA OF EPOXY ZINC-RICH PRIMER WITH DIFFERENT ZINC CONTENT | Everyone knows that the performance of epoxy zinc-rich primer mainly depends on its zinc content, and the zinc content also affects thezinc rich pa... | |

| Chlorinated Rubber Anticorrosive Primer (Iron Red) | Chlorinated Rubber Anticorrosive Primer (Iron Red) Chlorinated rubber anticorrosive primer is combined with a chlorinated rubber resin, curing age... |

Same products

| Epoxy Primer Sealer for Concrete Parts | Seller: Tianjin Jinhai Special Coatings & Decoration Co., Ltd | Epoxy primer-sealer for concrete parts is a two-component self-drying paint composed of epoxy res... | |

| Epoxy Phenolic Finish | Seller: Tianjin Jinhai Special Coatings & Decoration Co., Ltd | Epoxy phenolic paint is a two-component product, a special paint composed of epoxy resin, phenoli... | |

| FUXI ® EPOXY PAINT | Seller: Tianjin Jinhai Special Coatings & Decoration Co., Ltd | Liquid epoxy paintare the most important category of anti-corrosion coating products. They are... | |

| Epoxy MIO Intermediate Paint | Seller: Tianjin Jinhai Special Coatings & Decoration Co., Ltd | The epoxy MIO paintis composed of epoxy resin, mica iron oxide-based anti-rust pigments, solvents... | |

| Epoxy Intermediate Floor Paint | Seller: Tianjin Jinhai Special Coatings & Decoration Co., Ltd | This product is made of specially modified epoxy resin, high-quality solvent, additive, special a... |