TOWER PACKING/COLUMN PACKING

Leading Tower Packing/Column Packing

Tower packing refers to the tower packing in the packed tower. The function of tower packing is to provide sufficient contact surface for the gas and liquid phases, and to create conditions for improving the turbulence (mainly gas phase) to facilitate mass transfer (including heat transfer)

Tower packing has the advantages of large production capacity, high separation efficiency, small pressure drop, small liquid holding capacity, and large operating flexibility.

Column packing produced by tower packing manufacturers like NAIKE chemical is especially suitable for vacuum distillation, distillation under normal pressure and medium pressure, and of course the two-phase contact process of the atmosphere (such as gas absorption, cooling, etc.), but be particularly cautious when apply it in high-pressure rectification towers.

Tower Packing Types By Shape

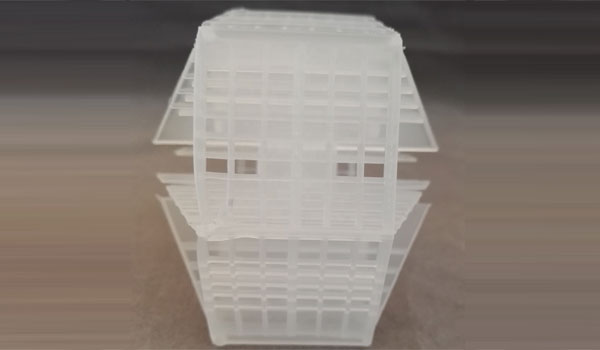

Structured Packing

Structured packing is also called Distillation Packing Bed, which has large specific surface area and low pressure drop, be widely used in distillation, absorption, stripping, desorption, heat exchange, extraction,etc.

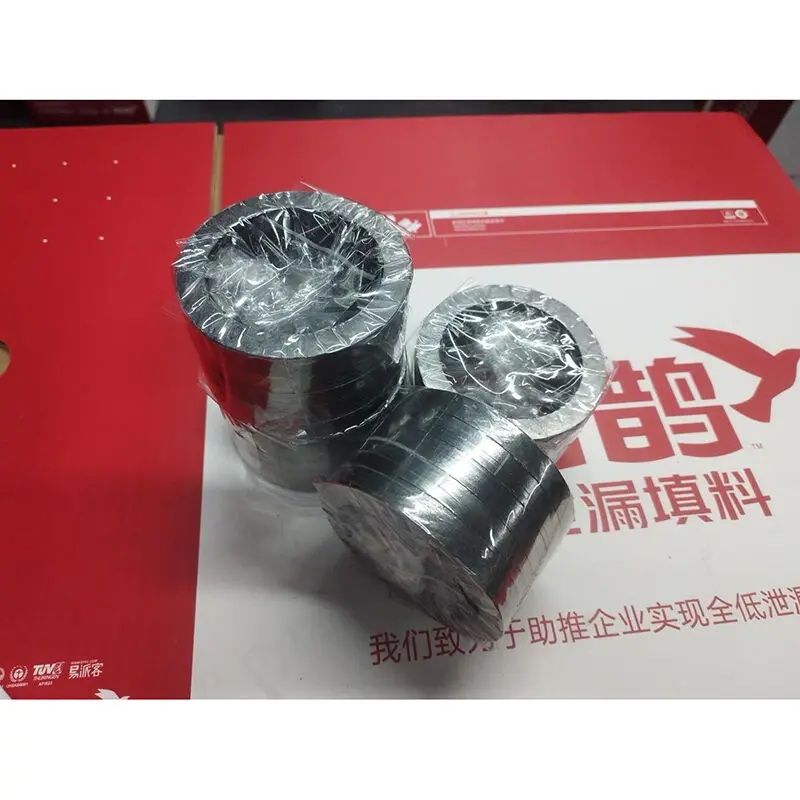

Random Packing

We can supply all shapes and materials in the area of tower packing, right from the simple sphere through the high-performance tower packing.

Ceramic Ball

The ceramic balls produced by our company are mainly divided into the following categories:Inert alumina ballActivated alumina ballGrinding ballRegenerative ballWater treatment filter ceramic ball.

Other supplier products

|

|

CERAMIC STRUCTURED PACKING |

Ceramic Structured Packing

Ceramic structured packing is made up of many packing unit bodies that share the same geometry shape. Corrugated cera... |

|

|

CERAMIC PALL RING |

Ceramic Pall Ring

Ceramic Pall Ringis a kind of random packing further developed based on Raschig Ring, with two layers of windows opened along it... |

|

|

Pad Demister/Mist Eliminator |

Wire mesh demister, also known as a wire mesh mist eliminator, is a kind of vapor liquid separating device. It is widely used in the chemical, petr... |

|

|

Lanpack |

Plastic Lanpack PackagingFor Tower Packing is the most distinguishing feature. This design enables an extraordinarily high scrubbing efficiency whi... |

|

|

CERAMIC RASCHIG RING |

Ceramic Raschig Ring

Ceramic Rasching Ringhas excellent acid resistance and heat resistance. It can resist to corrosion of various inorganic acids... |

All supplier products

Same products