Hydrogen Peroxide Production Plant

There are several methods for , among them the AO(auto-oxidation) process is the most prevailing one. In this process, 2-alkyl anthraquinone is mixed with organic solvent to make up the working solution, which is hydrogenated in presence of catalyst, and the resulting is oxidized by air (or oxygen) in counter-current way before being extracted, regenrated, purified and enriched to get commercial hydrogen peroxideproduct. Depending upon the different reactor type in the hydrogenation unit, AO process is further divided into Fixed Bed Reactor Process and Fluidized Bed Reactor Process. SL Tec provides both processes.

For this , SL TEC cooperates with one of the branch companies ofSEDIN Ningboto offer a turnkey hydrogen peroxide plant.

The Fluidized Bed Reactor Process SL TEC offers uses heavy aromatics-TBU binary solvent in the working solution(WS) system, with the WS capacity (H2O2-kg/m3-WS) reaching 12g/L.

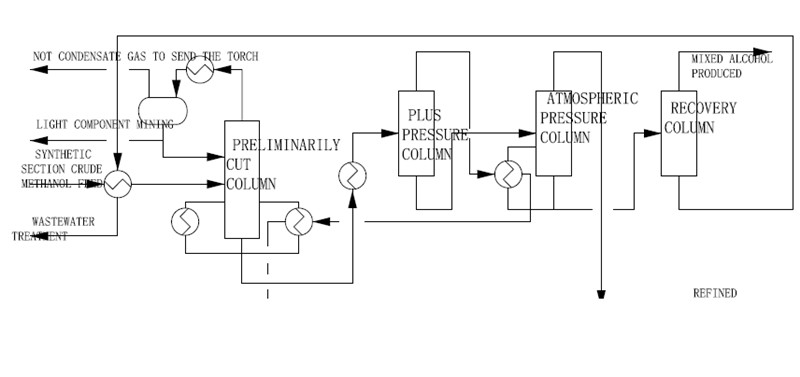

Process Flow Descriptionof

The working solution (WS) is pressurized and enters into the WS Temperature conditioner before being charged to the bottom of the hydrogenation column with Pd catalyst; fresh hydrogen from the surge tank is filtered and combined with the recycling hydrogen from the hydrogen compressor before entering the bottom of the hydrogenation column. The WS and hydrogen flows up in a co-current way, part 2-EAQ is hydrogenated to HEAQ, and the non-reacted hydrogen flows from the hydrogenation column to the separation and cooling unit before mixing with the fresh hydrogen and enters into the hydrogenation column again.

The hydrogen and the hydrogenated solution goes through gas-liquid separation, and the resulting hydrogenated solution is filtered, cooled and fed to the hydrogenated solution storage tank. While the filtered Pd catalyst powder is re-flushed by the re-flushing liquid into the bottom of the hydrogenation for re-use.

The hydrogenated solution in the storage tank is pressurized, and goes through two-stage filters to avoid the entering of the catalyst powder into the hydrogen peroxide solution and causing any possible mistake.

The oxidation column consist of air distributor, re-distribution plate, distribution cooler and packings. In this column, the hydrogenated solution from the last step is oxidized and the oxidation solution is obtained. The off-gas obtained from gas-liquid separation is cooled and condensed to get the mixture of aromatic and water before entering into the off-gas recovery cooler to have heat exchange with the low temp. oxidation gas from the expander. The heat exchanged off-gas enters into the off-gas recovery tank to separate out the condensed aromatic, which is to be recovered.

More information please via:

Send product request

Other supplier products

| Acrylic Impact Resistant Modifier | is mainly used to improve the impact properties and processability of PVC. PVC is important among general plastics. It has high strength, low pri... | |

| Methylal Refining Technology | Methylal Refining Technology Proprietary Technology and Plants Technical Features: Methaldehyde has excellent physical and chemical properties, tha... | |

| PODE Plant | is a kind of oligoether compound which is produced by acetalization reaction. When both ends of poden are blocked by methoxy, it is called polymet... | |

| Proprietary Technology and Plants | Dimethyl Carbonate (DMC) Refining Technology Proprietary Technology and Plants TechnologyIntrodction: Dimethyl carbonate (DMC) is an important o... | |

| Proprietary Technology and Plants manufacrurer | Ethyl Acetate Plant and Process Technology Proprietary Technology and Plants Technology Introduction: There are 4 main prevailing processes for ... |

Same products

| Epoxy Powder Coating/powder coating paint company | Seller: Standard International Group (HK) Limited | We are a professional epoxy powder coating manufacturer in China, offering factory-direct supply,... | |

| L-Cysteine S-Sulfate Na Marke quotation | Seller: 846340 | Carboxylate Group (-COO^-) Reactivity of L-Cysteine S-Sulfate Na The carboxylate group is in a de... | |

| L-Cysteine S-Sulfate Na Supply price | Seller: 846340 | Amino Group (-NH_2) Reactivity of L-Cysteine S-Sulfate NaThe α-amino group in the molecule ... | |

| High purity L-Cysteine S-Sulfate Na | Seller: 846340 | Hydrolysis Properties of L-Cysteine S-Sulfate NaThe functional groups in L-cysteine S-sulfate sod... | |

| High quality L-Cysteine S-Sulfate Na | Seller: 846340 | Redox Properties of L-Cysteine S-Sulfate NaTheS-sulfonate-thiol linkage (-S-SO_3^-)is the core st... |