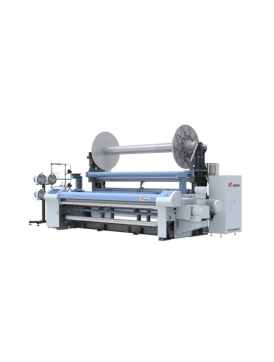

RFJA32 Fiberglass Weaving Machine

RFJA32 Fiberglass Weaving Machine

The RFJA32 Fiberglass Air Jet Loomis a specialized weaving machine designed for the production of glass fiber fabrics. This type of loom uses an air jet mechanism, which involves shooting the weft yarn across the loom using a jet of air. This method is highly efficient and allows for high-speed weaving. The RFJA32 fiberglass weaving machineis specifically designed to handle the unique properties of glass fiber, which is known for its strength, durability, and heat resistance. This makes it ideal for producing fabrics for industries such as aerospace, automotive, and construction, where these properties are highly valued.

Features of RFJA32 Fiberglass Air Jet Loom

1

Automatic Control System: Implementing a high-performance 32-bit computer enables real-time transfer of operational parameters, data collection, and adjustments, offering both the hardware reliability and software assistance necessary for achieving autonomous operations, digital administration, and network-based supervision in the facility. This technology not only delivers abundant information but also boasts a lifespan that is double that of the intelligent keyboards typically utilized in China, specifically in the context of fiberglass weaving machines.

2

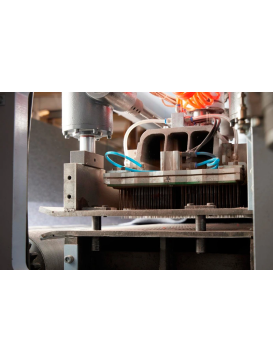

Beating Mechanism: Based on the characteristics of glass fiber fabric, adopt the special 4-link beating mechanism for glass fiber designed and optimized by computer. The beating motion is featured at short travel, small vibration, and long weft insertion time. The fiberglass air jet loom can make strong and stable beating during ultra-high speed operation and ensure weave high-quality fabric products.

3

Take-Up Mechanism: The rolling cloth fell support rod, stretching roller and cloth pressing roller completely eliminate the “removed weft” phenomenon caused by the winding of glass fiber fabric, to maintain a good style of the cloth surface off-machine. The take-up roller and cloth guide roller are wrapped with special friction materials to avoid pressure mark of the fabric.

4

Weft Insertion System: Adopt weft insertion components, e.g. weft feeder, main nozzle, auxiliary nozzle and stretch nozzle specially adapted to glass fiber yarn to meet the weft insertion needs of glass fiber yarn, reduce the damage to glass fiber weft yarn, reduce the wear of yarn to weft insertion components, and extend service life.

5

Double Back Rest Electronic Let-Off Mechanism: The double back rest electronic let-off mechanism specially designed for fiberglass loom machinerycan accurately measure and maintain the warp tension. The control accuracy and response speed are improved significantly via AC servo motor driving technology, which can ensure the surface quality of glass fiber fabric.

6

High Efficiency Air Suction Device: The high-efficiency air suction device on the fiberglass weaving machine can effectively absorb the fine fibers produced during weaving, and it is helpful to the physical and mental health of operators.

7

Take-Up Mechanism: The control technology in combination of AC servo motor drive and angular displacement sensor can control the winding tension constantly and realize more accurate winding. Adopt large winding mechanism on the machine, with the maximum winding diameter can reach 800mm, which not only realizes large winding length, but also significantly reduces the floor area of equipment. The quick doffing mechanism of our fiberglass loom machinery makes doffing simple and fast.

8

Special Scissors Temple Mechanism: Based on the characteristics of high hardness and being difficult to cut of glass fiber, the fiberglass weaving machine specially designs cutting scissors to cut off the excess yarn head, featured at low cost, good effect and long service life.

As a textile machinery company, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

| RFJW03 Water Jet Looms | RFJW03 Water Jet Looms RFJW03 series water jet loomis suitable for weaving light and medium-thickness fabrics. Drawing on Rifa's experience in dev... | |

| RFAD10 Full-Automatic Drawing-In Machine | RFAD10 Full-Automatic Drawing-In Machine RFAD10 full-automatic drawing-in machineis a kind of drawing-in equipment based on seed yarn mode. Drawin... | |

| Needle Punched Non-woven Fabrics Production Line | Needle Punched Non Woven Needle Punching Machine The Needle Punched Non-woven Fabrics Production Line from RIFA is an advanced system designed for... | |

| Needle Punched Non-woven Fabrics Production Line | Needle Punched Non-woven Fabrics Production Line The needle punching machinefrom RIFA is an advanced system designed for the production of high-qu... | |

| Spun-Laced Non-woven Fabrics Production Line | Spun-Laced Spunbond Non Woven Fabric Machine The spunlace linefrom RIFA is a cutting-edge system designed for the production of high-quality non-w... |

Same products

| Spun-Laced Non-woven Fabrics Production Line | Seller: ZHEJIANG RIFA TEXTILE MACHINERY CO., LTD | Spun-Laced Non-woven Fabrics Production Line The Spun-Laced Non-woven Fabrics Production Line fr... | |

| Needle Punched Non-woven Fabrics Production Line | Seller: ZHEJIANG RIFA TEXTILE MACHINERY CO., LTD | Needle Punched Non-woven Fabrics Production Line The needle punching machinefrom RIFA is an adva... | |

| Non-woven Fabric Machine | Seller: ZHEJIANG RIFA TEXTILE MACHINERY CO., LTD | NonWoven Fabric Machine RIFA’s nonwoven slitting machineis a groundbreaking addition to th... | |

| RFJA32 Fiberglass Weaving Machine | Seller: ZHEJIANG RIFA TEXTILE MACHINERY CO., LTD | RFJA32 Fiberglass Weaving Machine The RFJA32 Fiberglass Air Jet Loomis a specialized weaving mac... | |

| RFJAT28 Air Jet Terry Looms | Seller: ZHEJIANG RIFA TEXTILE MACHINERY CO., LTD | RFJAT28 Air Jet Terry Looms The RFJAT28 Air Jet Terry Loomis a specialized weaving machine desig... |