Fluid Bed Granulator Substitute Hot Selling Laser Welding Plate Heat Exchanger

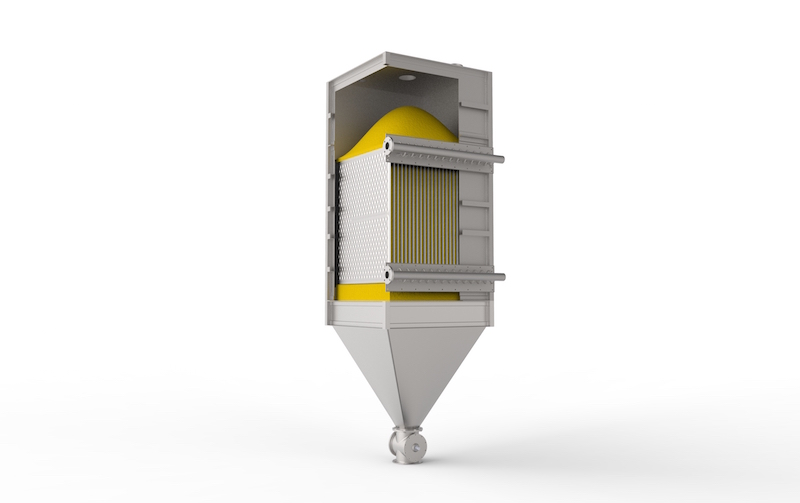

SV bulk solid heat exchanger is a kind of heat exchanger using pillow plate to heat or cool bulk solid particle or powder.

Technical features:

- Dense phase conveying design: The speed and temperature of powder discharging is even and controllable, with stable and reliable quality.

- Wall type heat exchange: Heat exchange medium exchanges heat with powder by high efficient pillow plate, no direct contact with powder.

Product Advantages:

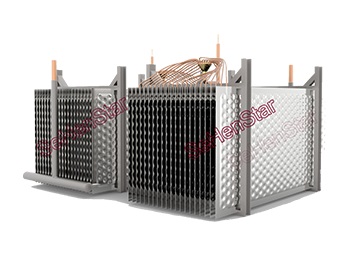

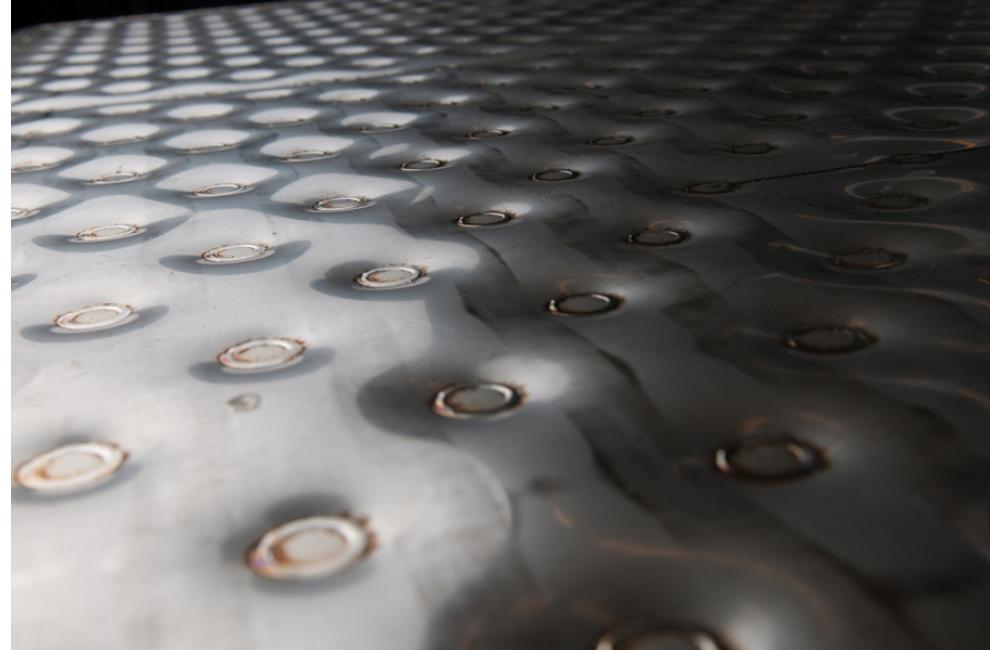

- World leading laser welding pillow plate heat exchange technology:

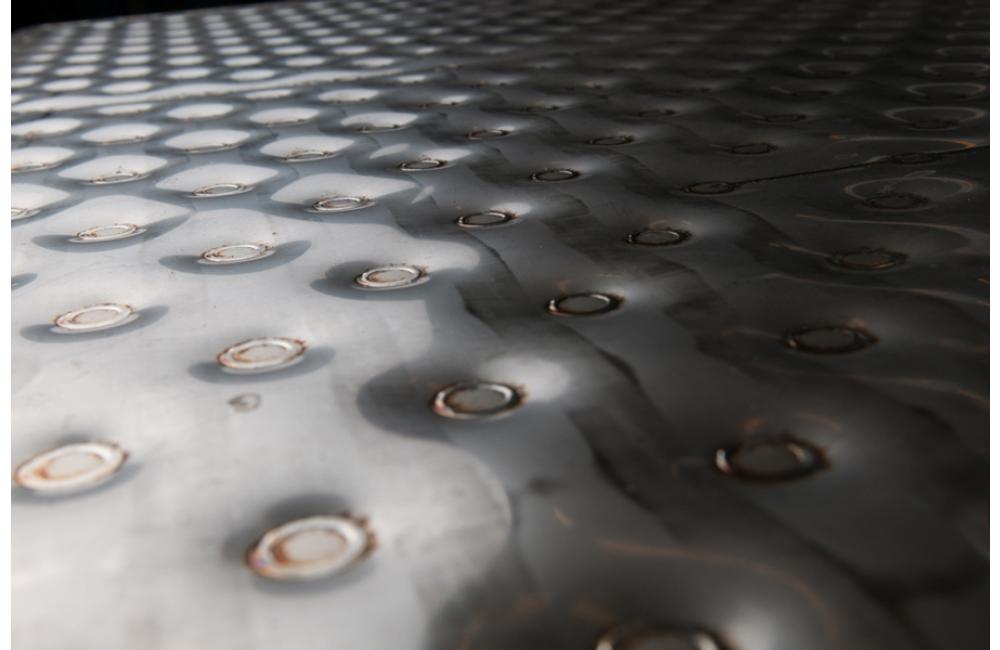

Pillow plate is laser welded by two plates all around and in the middle area full of weld flowers. After the forming process, the inner part of the heat exchange plate forms a pillow type cavity. Pillow design creates excellent turbulence and provides self supporting structure. In practical applications, the additional welding path is often added in the pillow heat exchange plate, in order to adjust and control the flow of fluid into and out of the heat exchange plate nozzle position, the fluid velocity and flow rate inside plate, so as to optimize the heat exchange effect.

Technical advantages of pillow plate:

1)Excellent turbulence design, high heat exchange coefficient

2)High welding realiability

3)Small external surface resistance, not easy to product dirt

4)High temperature and high pressure resistance

5)Wide channel, low pressure drop, easy to clean

6)Flexible shape to maintain optimal heat exchange effect

- Full closed operation with zero emission:

In the process of using wall type heat exchange technology of SV bulk solid heat exchanger, there will be no direct air contact with bulk solid. So it fundamentally eliminates dust, fine particles and odor emissions, as well as prevent dust explosion effectively.

- Saves energy up to 90%:

Compared with the traditional heat transfer technology, the energy consumption of SV powder flow heat exchanger is decreased by more than 90%

- Ensure superior product quality:

The controllable low velocity when the powder passes through the heat exchanger can effectively prevent the wear and tear and decomposition of product. Also ensures the particle properties and crystal shape, so as to achieve the best product quality.

- Even heat exchange effect:

Based on dense conveying principle, powder in the heat exchanger flows evenly and in low speed, which ensures the even temperature of product discharging. Also the temperature of final product has good consistency.

- Modular structure, easy to expand:

The vertical structure of SV bulk solid is compact and modular. The processing amount could be adjusted by increasing or decreasing pillow plate quantity. It saves lots of installation space.

- Compact structure, easy to install

The wall type heat exchange and dense conveying designs means there is no need of high power consumpting equipment, such as electric motor, fan, dust catcher and emission control systems.

Comparison of SV bulk solid heat exchanger with fluid bed and drum dryer

|

SV bulk solid heat exchanger |

Fluid bed |

Drum dryer |

||

|

Operation energy consumption |

Low |

High |

High |

|

|

Installation cost |

Low |

High |

High |

|

|

Maintenance cost |

Low |

Medium |

High |

|

|

Material degradation |

No |

High |

High |

|

|

Modular structure |

Yes |

No |

No |

|

|

Compact design |

Yes |

No |

No |

|

|

Exhaust and dust emission |

No |

Yes |

Yes |

Application:

SV bulk solid heat exchanger is used in the process of on-line cooling and heating of solid particles, including chemical, fertilizer, polymer, mineral, sand and bulk crop, etc. SV bulk solid heat exchanger uses simple and easy to access medium to exchange heat. For example, cool water from cooling tower or water chilling unit for powder cooling; hot water, steam and heat conducting oil to heat powder. In most applications, energy could be recovered by SV heat exchanger, so enables users to obtain multiple benefits.

在线联系供应商

Other supplier products

| Effective Energy Saving and Environment Protection Heat Exchange Immersion Plate Heating Plate | Pillow Plate is a highly versatile panel-type heat exchanger that can be welded, formed, or fitted to meet your exact needs. It can be applied in i... | |

| Low Energy Consumption and Environmental Protection Pillow Plate Heat Exchanger for Fresh Produce | SPI immersion heat exchanger is applied for working condition of liquid heating, cooling and heat recovery. SPI immersion heat exchanger is based o... | |

| Ice Machine Maker Plate Heating Plate | Pillow Plate is a highly versatile panel-type heat exchanger that can be welded, formed, or fitted to meet your exact needs. It can be applied in i... | |

| Solid Cooler Energy Saving Laser Welded Exchanger | SV bulk solid heat exchanger is a kind of heat exchanger using pillow plate to heat or cool bulk solid particle or powder. Technical features: ... | |

| Hot Selling Laser Welding Immersion Low Energy Consumption and Environmental Protection Pillow Plate | Pillow Plate is a highly versatile panel-type heat exchanger that can be welded, formed, or fitted to meet your exact needs. It can be applied in i... |