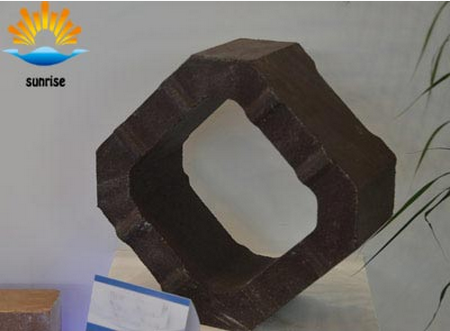

Clay refractory brick

Clay refractory brick is refractory clay refractory products. It is widely used in industry. Clay brick refractory bricks are divided into ordinary clay bricks, clinker clay bricks, clay bricks and high-silica content of clay bricks and other varieties.

Clay refractory brick is acidic refractory material, with the brick Al2O3 content increases its acid gradually weakened. Its thermal conductivity is the lowest of all refractory materials. Although the fire resistance of up to 1700 ° C, but the load softening temperature is only about 1300 ° C, which is the biggest drawback of clay bricks, it can not be used at high temperatures, can not be under pressure. When it is attacked by a large amount of R2O, its softening temperature is further reduced to about 1050 ° C, so it can only be used in the lower part of the wall or in the lower part of the bottom.

Clay refractory brick thermal expansion rate is the smallest of the commonly used refractory materials. At the same time due to the small crystalline clay brick, stomata small and evenly distributed, so that the stress is easier to be buffered, so in a wide range of thermal shock resistance. Low temperature in the lower part of the regenerator Plaid bricks, flue and day glass furnace Furnace refractories near the feeder such as punch, bowl and other places require good thermal shock resistance, can play its role.

Clay brick manufacturing methods are more, you can hand molding, ramming molding, extrusion molding, mud casting and molding machine and other high-pressure molding. Different molding methods, the nature of products are very different. Even the chemical composition of the same type of raw materials, but also because of its different methods of forming brick caused by different properties. According to different parts of the use of different molding methods. Regenerative cells Lattice brick, brick size is small, with high pressure press molding products for the best; for large pool wall tiles, trough tiles and other vacuum exhaust using the best mud casting method; and the size of the exact product Molding method better.

The clay bricks used by friends all know that clay bricks are very useful, but sometimes we will meet the damaged clay bricks, and this is damaged brick that is due to the firing time is too high temperature formed, so that We need to control the firing temperature, today we will introduce the burning of clay brick needs to control the size of it.

Clay refractory bricks at the time of firing the level can be divided into a and two, in the time of its firing temperature is about 1440 ℃, up and down ups and downs can not exceed 50, the usual holding time is 40h. However, when faced with three levels of clay brick temperature control 1400 ℃, insulation moment is shorter than the previous two. I met in the tunnel using a second grade refractory fired at a temperature of 1500-1560 at the mercy of the temperature scale. Depending on the firing of different materials and finished products, the rate of warming is not the same. The rising temperature should be controlled at 600 ℃, and then start to change a little bit according to the difference, until the temperature is 1200 ℃. There is that we should pay attention to the temperature of the cooling time to do a good job.

在线联系供应商

Other supplier products

| Magnesia Chrome Brick | Description:♦ High strength ♦ Corrosion resistance♦ Erosion resistance ♦ Excellent slag resistance ♦ Good thermal shock stabilityIt is made with si... | |

| Magnesia Brick | Magnesia Brick Features: Excellent performance of basic slag resistance, high refractoriness, thermal stability, anti-erosion and anti-peelingExcel... | |

| Improve the service life of chrome corundum bricks for gasifiers | The main factors influencing the service life of chrome corundum bricks include gasifier load, operating temperature, coal ash melting point, ash c... | |

| Hot! magnesia refractory bricks for kilns | Specifications 1. Excellent thermal shock resistance2. High refractoriness under load3.Good mechanical strength Magnesia bricks: 1. The pr... | |

| High Alumina Insulating Brick | DescriptionHigh alumina insulating bricks are also known as high alumina heat insulating bricks. It is a new type of lightweight insulating materia... |

Same products

| YC160W Wheel excavator YC160W | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |