OIL PURIFIER choose Filter equipment and accessories, its U

Henan Uters International CO.,LTDfocus on High quality and excellent service Gas separation filter,In short supply FILTER CARTRIDGE,PALL FILTER s brandandGood quality and excellent service Filter housing, is committed to be listed into Chinas Industry filter industry well-known brands .With the original concept of new media marketing, novel, fast development and mature, high quality, accurate for the unique characteristic expression of corporate strategy , We provide customers with all-round good OIL PURIFIERservice.

Henan Uters International CO.,LTD have Good quality and excellent service Filter housing,With a long history HYDAC FILTER,panel filter specialty,nasal air filter insert volvo,Easy to use Hydraulic Filters,pleated filter specialty and other areas of expertise, combined with excellent service capabilities, To provide customers with professional, customized Industry filter. Moreover, since the establishment of a long time ago,the Filter equipment and accessoriesbusiness of UTERS has always maintained a high-speed and stable growth. details:

Working principle of filter

Working principle, when the filter works, the water to be filtered is entered from the nozzle and flows through the filter.

The granular impurities in the water are intercepted inside the filter. This constant cycle, more and more particles trapped down, filtering speed more slowly, and imported into the sewage is still Everfount, filter holes will become increasingly smaller, resulting in pressure difference between inlet and outlet, when largeddifference reaches the set value, the differential pressure transmitter electrical signals will be transmitted to the controller, control system start the drive motor to rotate through the transmission shaft assembly drives the sewage outfall, at the same time open, discharged from the sewage outfall, when the filter cleaning is finished, the pressure dropped to the minimum value, the system returns to the initial filter, the normal operation of the system. The filter is composed of a shell, a multiple filter core, a backwashing mechanism, and a differential pressure controller. The diaphragm of the shell is divided into two chambers, the upper cavity and the lower one. The upper chamber is equipped with a plurality of filter cores, so that the filter space is fully reduced, and the volume of the filter is significantly reduced. The backwashing chuck is installed in the lower cavity. When working, the emulsion entrance into the filter chamber, and the inner baffle hole into the filter. The impurities which are larger than the filter core are intercepted, and the net liquid goes through the gap to the upper chamber, and then it is sent out from the exit. The filter uses high strength wedge-shaped filter net to automatically clean the filter core through pressure difference control and timing control. When the impurity in the filter is accumulated on the surface of the filter element, causing the inlet and outlet pressure difference to increase to the set value, or when the timer reaches the preset time, the electric control box sends out a signal to drive the backwashing mechanism. When the backwash suction port and the filter is imported when the sewage valve is opened, the pressure relief drainage system, the sucker and the inside of the filter is a relative pressure below the negative pressure zone of the filter lateral pressure, forcing some clean circulating water from the outside into the inside of the filter cartridge, adsorption of impurities particles in the filter on the inner wall with the water flow into the Rang disc and is discharged from the drain valve. A specially designed filter makes the interior of the filter produce a jet effect, and any impurity will be washed away from the smooth inner wall. When the pressure difference between the inlet and outlet of the filter is restored to normal or the timer setting time is over, during the whole process, the material is not broken down, and the water consumption of backwashing is less, which realizes continuous and automatic production. The filter is widely used in the fields of metallurgy, chemical industry, petroleum, papermaking, medicine, food, mining, electric power and urban water supply. Such as industrial waste water, circulating water filtration, emulsion regeneration, waste oil filtration treatment, continuous casting water system and blast furnace water system in metallurgical industry, and high pressure water descaling system for hot rolling. It is an advanced, efficient and easy to operate fully automatic filter.

The water to be treated by the filter is entered into the body from the inlet, and the impurities in the water are deposited on the stainless steel filter network, resulting in the pressure difference. The pressure difference of the inlet and outlet is monitored by the differential pressure switch. When the pressure difference reaches the set value, the electronic control device gives the hydraulic control valve to drive the motor signal. Equipment installation, debugging by the technical staff, filtration time and cleaning time conversion, the water to be treated into the body from the water inlet filter to begin work, when it reaches the preset cleaning time, electric controller for hydraulic control valves, motor drive signal, triggered a series of actions: the motor drives the rotation of the brush to clean. At the same time filter, the control valve is opened to discharge, the whole cleaning process needs to last only tens of seconds, when cleaning at the end, close the control valve, the motor stops rotating, the system returned to its initial state, began to enter the next filtering process. The inner part of the filter is mainly composed of coarse filter screen, fine filter screen, suction pipe, stainless steel brush or stainless steel suction nozzle, sealing ring, anticorrosive coating, rotating shaft and so on. A filter is formed by separating the container into the upper or lower chamber with the filter medium. The suspension is added to the upper cavity. Under pressure, it enters the lower cavity through filtration medium and becomes filtrate. Solid particles are trapped on the surface of filtering medium to form filter residue (or cake). During the filtration process, the filter slag layer gradually thickened, the resistance of liquid through the slag layer increased and the filtration speed decreased. When the filter chamber is filled with filter residue or filtration speed for too small hours, the filter is stopped, filter slag is cleared, and the filter media is regenerated to complete a filtration cycle. The liquid must overcome the resistance by filtering the slag layer and the filter medium, so there must be pressure difference on both sides of the filter medium, which is the driving force for filtering. The pressure difference can accelerate the filtration, but the pore of the filter medium is easily blocked in the large pressure difference after the pressure difference, and the filtration is slowed down.

There are 3 kinds of filtration methods: filtration of slag layer, deep filtration and sieve filtration.

Filter slag filter: the filtration medium at the initial stage of filtration can only intercept the large solid particles, and the small particles follow the filter medium with the filtrate. After the formation of the initial slag layer, the slag layer plays a major role in the filtration, and the large and small particles are all intercepted, such as the filter of the plate frame filter press.

(2) deep filtration: the filter medium is thicker, and the solid particles in the suspension are less, and the particles are smaller than the filter media. When the particles are filtered, the particles are adsorbed in the channel, such as the filter of porous plastic pipe and sand filter.

Filtration and filtration: the solids retained by filtration are greater than those in the filtration medium, and no solid particles are adsorbed inside the filtration medium, for example, the rotary filter screen can filter coarse particles in the sewage. In the actual filtering process, the three ways are often at the same time or successively>

As we all know, established in a long time ago,UTERS was a professional private enterprise engaged inHenan Province,Zhengzhou City,City area,North Third Ring Road ,wound filter,Metal Filters,oil filtration unitx1dd01f6n . With years of industry advantages, information accumulation and market development experience, UTERS has established a good and close business contacts with the majority of customers and friends . More cooperation intention to negotiate, please call the hotline: ,or visit our official website:

在线联系供应商

Other supplier products

| one-stop service Separate Air Compressor Filter,COMPRESSOR | Henan Uters International CO.,LTD is a professional company engaged in COMPRESSOR FILTERx1dd01f6n,PRECISION FILTER,FILTER CARTRIDGEand other projec... | |

| UTERSpanel filter, a professional one-stop service ofoil fi | Henan Uters International CO.,LTD founded in Henan Province,Zhengzhou City,City area,North Third Ring Road, is a professional production precis... | |

| Give Air filters a try | Henan Uters International CO.,LTDis a Lubricating oil filter,Stainless steel filterin one large multi-functional integrated modern enterprise,and d... | |

| Air Compressor Filter, you won't want to miss | Henan Uters International CO.,LTDis a company with Trustable wound filter,air filter elementx1dd01f6nandFilter housing as the main business. We are... | |

| UTERS panel filterhave not only reliable quality but also | Henan Uters International CO.,LTD was established in Henan Province,Zhengzhou City,City area,North Third Ring Road, is Chinese earlier established ... |

Same products

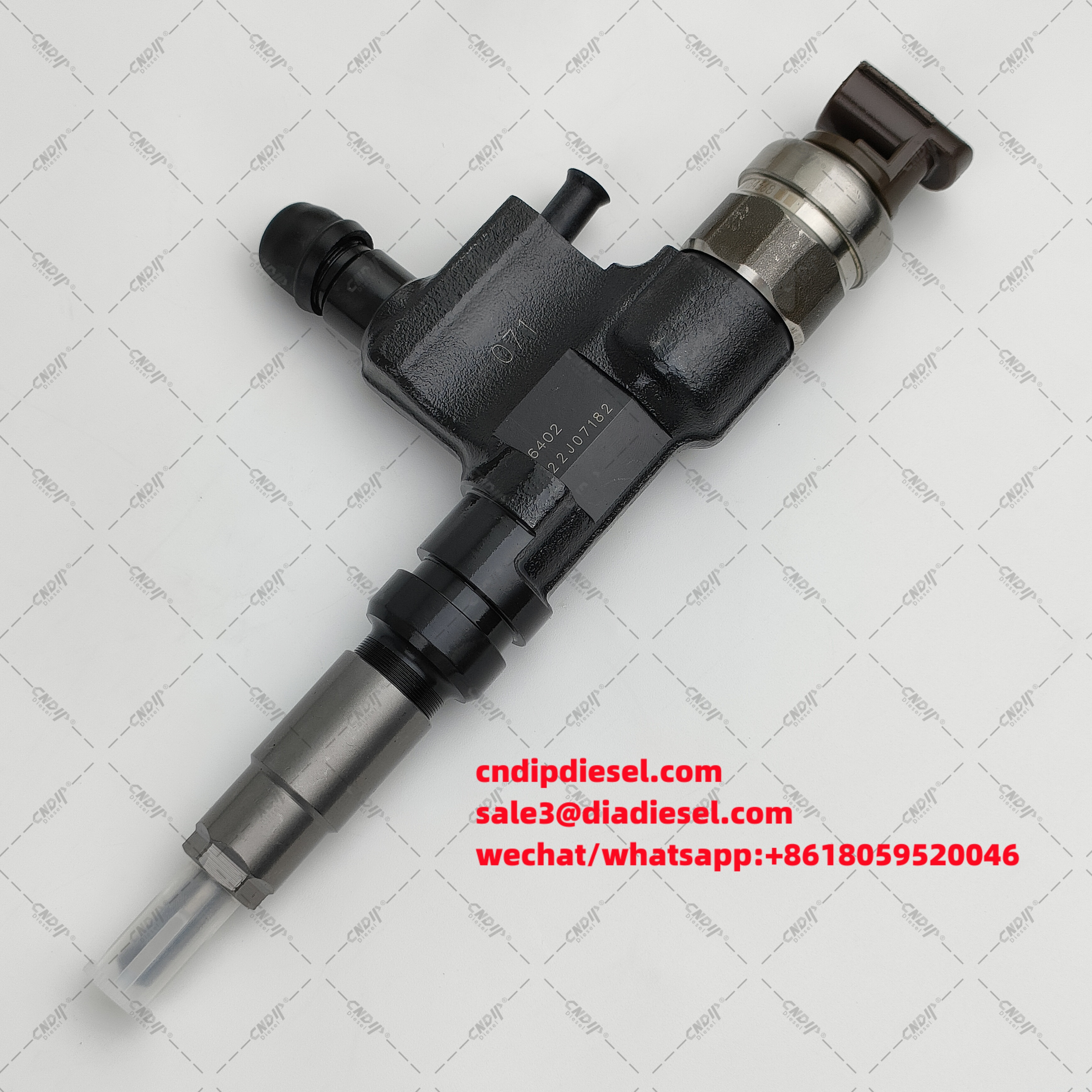

| 共轨喷油器 | 卖方: 德艾普(厦门)进出口有限公司 | 商品名称:柴油喷油器型号: 最小起订量:1 件 材质:钢 包装详情:纸箱包装 库存:有库存 品牌:CNDIP 质保:6个月 | |

| 共轨喷油器 | 卖方: 德艾普(厦门)进出口有限公司 | 商品名称:柴油喷油器型号: 最小起订量:1 件 材质:钢 包装详情:纸箱包装 库存:有库存 品牌:CNDIP 质保:6个月 | |

| 共轨喷油器 | 卖方: 德艾普(厦门)进出口有限公司 | 商品名称:柴油喷油器型号: 最小起订量:1 件 材质:钢 包装详情:纸箱包装 库存:有库存 品牌:CNDIP 质保:6个月 | |

| 帕劳灌装液氮罐KGSQ液氮瓶 | 卖方: 河南天之道生物科技有限公司 | 在生命科学研究中,液氮是较为常用的冷冻介质,储存它的容器则成了重要实验工具。实验进行中,为了样本的低温储存环境稳定,需要定期补液以保证充足供应,因为液氮易挥发,液氮量随时间推推移而减少。因此,为... | |

| Micronized Polyethylene Wax for Pigment Dispersant | 卖方: Syntop chemical Co.,Ltd. | Polypropylene wax is a chemical produced by pyrolysis, cut by heating and crushed by hot air It i... |