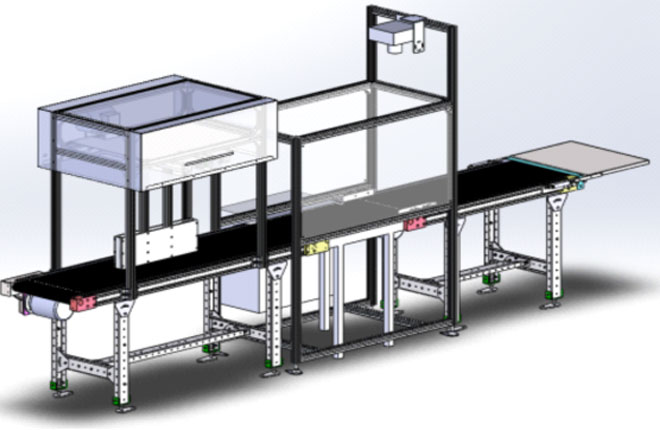

AUTOMATED SCANNING AND WEIGHING LINE(DWS)

Lisen Automation group is a national high-tech material handling system supplierthat provides integrated intelligent logistics solution, application technology and equipment, is a professional material handling equipment supplierof product manufacturing and circulation enterprises. After near 20 years of development, Lisen Automation has become a famous brand in the industry in China.

Four indicators: Small footprint, wide application range, labor force reducing, high efficiency

Automated scanningand weighing line: it's used at the inbound and outbound ends of parcels on each sorting conveyor belt, with camera installed for data identification, and can automatically read barcode, weigh the parcel and measure parcel dimension. Parcel scanning and weighing status (normal parcel or abnormal parcel) will be known after the system interchanging information with customer system. Normal parcel will directly pass through the automated weighing, and abnormal parcel will be pushed aside by partition for sorting operator to check and handle it. The automated vulnerability scanningand weighing line greatly reduces manual checking workload, and improves sorting efficiency, also cuts down the time and labor cost, thus it plays an important role and means a lot in parcel sorting.

Specification of Small Parcel DWS

|

Item name |

Parameter |

|

|

1 |

Overall dimension |

Width4800mmXLength1300mmXHeight1000mm |

|

2 |

Power supply |

Single phase220V Power1.43KW |

|

3 |

Conveying line speed |

|

|

4 |

Efficiency |

Theoretical efficiency up to 6000pcs/hr,actual efficiency 2000~3600pcs/hr |

|

5 |

Barcode reader |

HIKVISION/DATALOGIC/SICK/COGNEX(customizable) |

|

6 |

Dynamic scale |

Weighing range: 10g – 6Kg Weighing precision:±2g,±5g,±10g Maximum parcel size:Length400mmxWidth320mmxHeight250mm |

|

7 |

Dimension measuring |

Minimum parcel size: Length100mm xWidth60mm xHeight1mm Measuring precision:±10mm(HIKVISION)/ ± 5mm(datalogic/SICK) |

|

Item name |

Parameter |

|

|

1 |

Overall dimension |

Width4000mmXLength1300mmXHeight1500mm,angle 14 (customizable according to actual need)(Optional removing device, push plate, turntable, transfer conveyor can be added, or coordinating with sorter module) |

|

2 |

Power supply |

3phase380V Power4.1KW |

|

3 |

Conveying line speed |

|

|

4 |

Efficiency |

1800~3600pcs/hr(customizable) |

|

5 |

Barcode reader |

HIKVISION/DATALOGIC/SICK/COGNEX(customizable) |

|

6 |

Plane dynamic scale |

Weighing range: 300g – 60Kg Weighing precision:±10g,±20g,±60g(customizable) Maximum parcel size:Length1000mmxWidth700mmxHeight700mm |

|

7 |

Dimension measuring |

Minimum parcel size: Length200mm xWidth100mm xHeight100 mm Measuring precision:±10mm(HIKVISION)/ ± 5mm(datalogic/SICK) (customizable) |

Advantages of Automated Scanning and Weighing Line(DWS)

Linear design, compact structure, small footprint, much space saving

Wide application range, applicable for various goods with different sizes, shapes and natures, lower than 10kg, including very small and thin ones

Extremely low running noise

Low operation and maintenance cost, simple and safe to operate.

Application Industries of Small Parcel DWS

Cross-border e-commerce industry

Express industry

Postal industry

Application Scenarios of Small Parcel DWS

Cross-border e-commerce, Postal small packet service, warehouse inbound/outbound auto barcode reading, weighing and dimension measuring.

Application Industries of Large Parcel DWS

E-commerce industry

Express industry

Cosmetics industry

Application Scenarios of Large Parcel DWS

Applicable for small packet in e-commerce express industry, warehouse inbound/outbound auto barcode reading, weighing and dimension measuring.

We provide automated weighing scaleand automatic weighing system,etc.

在线联系供应商

Other supplier products

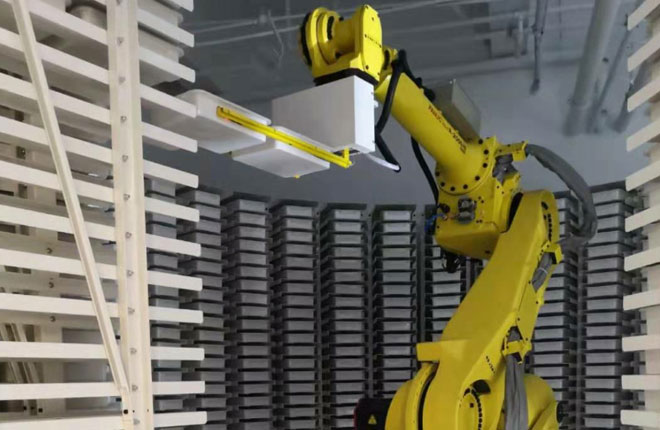

| ROBOTIC PICKING SYSTEM | Pick and place vision system: it consists of 6 major modules, including robot order picking system, robot piece picking system, robot de-palletizin... | |

| ROBOTIC PICKING SYSTEM | Robotic picking system : it consists of 6 major modules, including robot order picking system, robot piece picking system, robot de-palletizing sys... | |

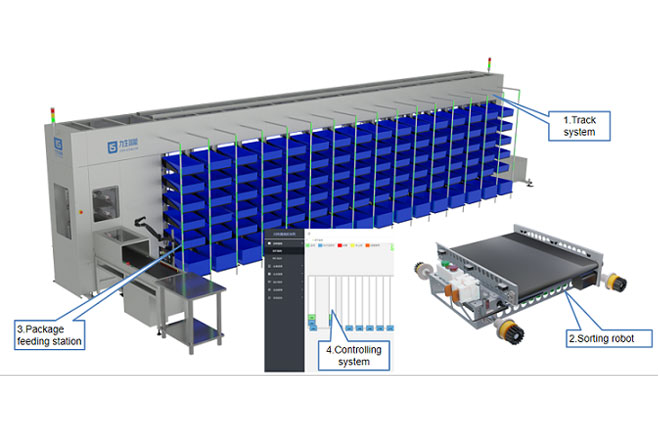

| AUTOMATED PUT WALL | Lisen Automation group is a national high-tech logistics solutions companythat provides integrated intelligent logistics solution, application tec... | |

| LOOP CROSS-BELT SORTER | Crossbelt sorter: cross belt sortersystem is mainly composed of parcel supply, sorter host, parcel discharging, and control system the four section... | |

| MOLD MONITOR | Mold monitor, also called mold protector and electronic eye, is a mold protection system mainly for monitoring, controlling and inspecting the oper... |