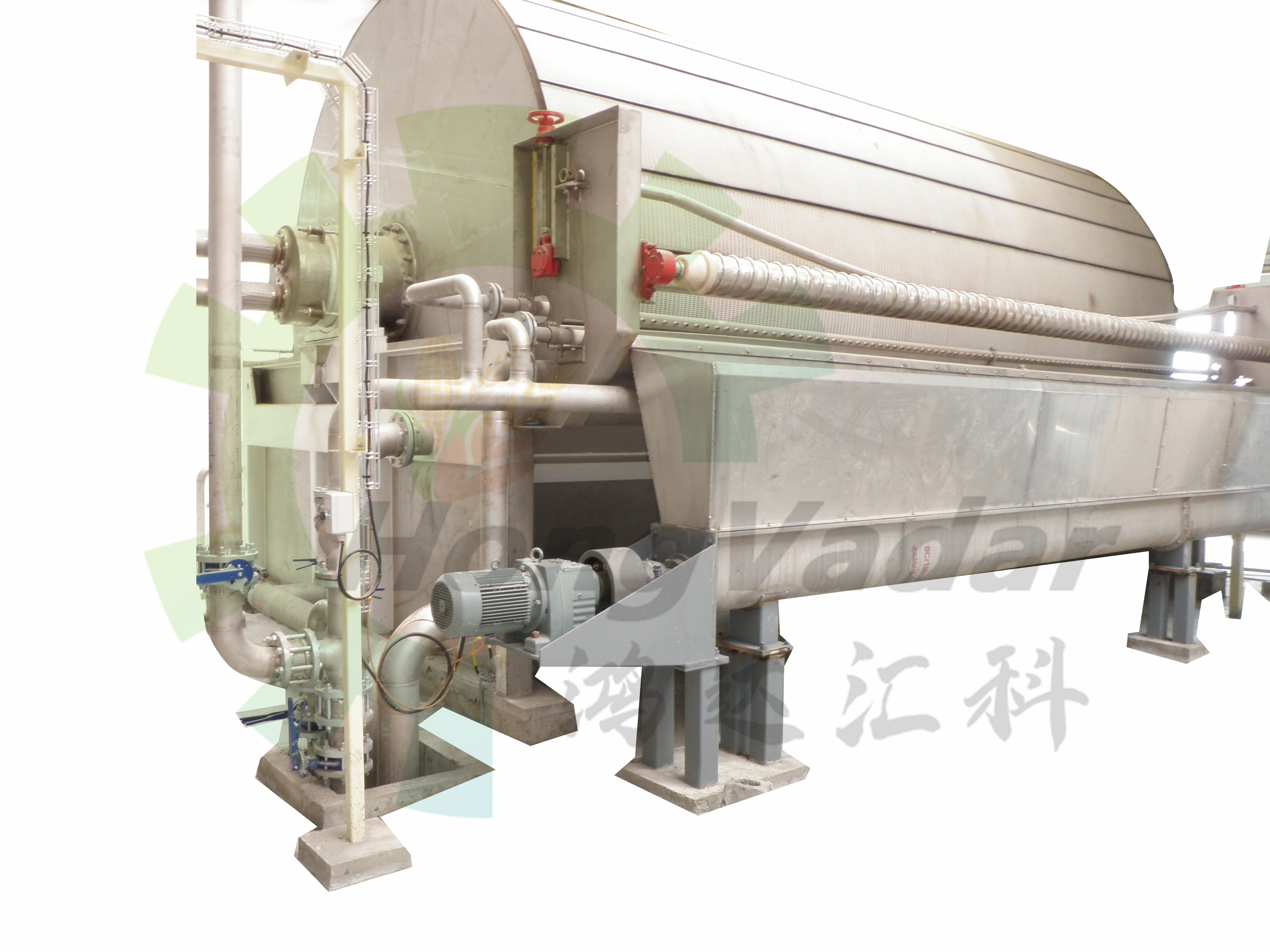

Liquefaction System

HongVadar Co. abides by the business philosophy of "Take honesty as the foundation and Keep credit to develop", adheres to the practice principles of scientific, standard and fair practice; To build the world-class systems engineering, intelligent and high-efficiency corn starch production plantas the goal; Strive to find engineering solutions technology partner, enlarge the business team and enhance the technical strength, and complete the internal management system and business operation procedures, to provide the most advanced and perfect technology, equipment and services for the domestic and foreign customers.

HVD-LF-Q liquefaction and reliquefaction system description: Starch milk from the starch production line is adjusted to meet the optimal working requirements for liquefaction. Add the high-temperature resistant α-amylase required for the starch liquefaction. Under the efficient shearing action of the jet cooker, the starch multi-branched chain was instantly opened to generate monosaccharides or polysaccharides. After a certain maintenance time, the starch milk was completely liquefied to meet the different DE value requirements for the production.

Features ofLiquefaction System

- High efficiency and high conversion rate.

- Automatic intelligent control, stable production, and low labor cost.

- Better flocculation effect of the protein, which is conducive to the subsequent process and the separation of the protein.

HongVadar relies on professional design, strict production management, the fine processing procedure, provides high efficiency and energy-savingliquefaction equipmentfor the customer. The liquefaction plantand reliquefaction planthas passed the international ISO9001 quality system certification, and with the design and manufacturing capacity of pressure vessels. Customers can choose international ISO, EU CE, and other standards for equipment design and production according to their needs.

Liquefaction SystemTechnical Parameter

|

Model |

Feed DS, % |

Jet cooking capacity, m3/h |

Liquefaction temp., ℃ |

Maintaining time, min |

Product capacity, tpy |

DE value |

|

HVD-LF-Q1.0 |

28-35 |

105-110 |

90-120 |

10000 |

20-98 |

|

|

HVD-LF-Q2.0 |

28-35 |

105-110 |

90-120 |

20000 |

20-98 |

|

|

HVD-LF-Q3.0 |

28-35 |

105-110 |

90-120 |

30000 |

20-98 |

|

|

HVD-LF-Q6.0 |

28-35 |

105-110 |

90-120 |

60000 |

20-98 |

|

|

HVD-LF-Q10.0 |

28-35 |

105-110 |

90-120 |

100000 |

20-98 |

|

|

HVD-LF-Q15.0 |

28-35 |

105-110 |

90-120 |

150000 |

20-98 |

|

|

HVD-LF-Q20.0 |

28-35 |

105-110 |

90-120 |

200000 |

20-98 |

Other Agriculture Processing Product

Let Us Know How We Can Help

在线联系供应商

Other supplier products

| Products | HongVader as agricultural processing plants play the roles of corn, sweet corn processing plant, potato processing plant, starch of corn and wheat ... | |

| Liquefaction System | HongVadar company provides you the Lysine, Tryptophan, Threonine, Valine, Leucine, etc. fermentation products project. HongVader as agricultural pr... | |

| Desand Cyclone and Germ Cyclone | Desand Cyclone HVD-CY-DS series desand cyclone is mainly used in starch production to remove sediment, metal particles, and other impurities in st... | |

| 12-stage Hydrocyclone System | VD-HC-D series 12 stage starch washing hydrocyclone systemis mainly used to extract refined starch milk, that is, to remove soluble and insoluble p... | |

| Rotary Vacuum Filter | Pre-coating Vacuum Filter System HVD-PVF-P series pre-coating vacuum filter works on the same principle as the general rotary vacuum filter in sug... |