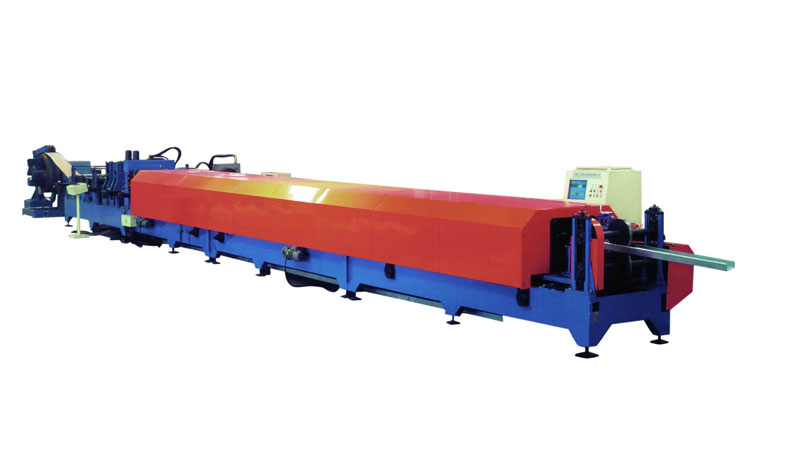

Fully Automatic CZ Purlin Roll Forming Machine

The fully automatic C/Z steel integrated machine is also called the C/Z interchange molding machine, and C and Z interchange purlin machine. The fully automatic CZ purlin machine provides users with highly automatic roll forming machinethat can realize the interchange production of C/Z two models and various specifications purlins in a short time by PLC computer control. The production process of the fully automatic C and Z interchange purlins is completely automatic, and there is no need to change the forming rollers when changing the specifications. The invention of theC&Z purlin forming machinehas changed the history of processing C and Z different purlins by using two different C and Z equipment, saving users lots of investment cost and space.

Features and Advantages of Fully Automatic C&Z Purlin Roll Forming Machine

Fully automaticmulti-size adjusting on PLC screen.

FullyautomaticC & Z changeover mode on PLC screen.

High Forming speed: 30m/min

Certified with Multi-Patents; CECertified, EUROPEANquality standard

Most of the hot & popular profiles models, we have ready machines in stock for prompt delivery.

Suitable Coil Sheet Material for Fully Automatic C&Z Purlin Forming Machine

Suitable material: Cold/hot Rolled Steel, Galvanized Steel

Thickness: 1.6-3.2(mm)

Yield Strength: 230-300 (MPa)

Width: as profile requests

Production Line Components and Parameters of FullyAutomatic C&Z Purlin Forming Machine

FullyAutomatic C&Z Purlin Forming Machine

|

3t/5t automatic |

|

|

30m/min |

|

|

closed type |

|

|

Automatic Stacker |

|

|

Power supply for pre-cutting and hole punching system |

|

|

industrial computer communicates with PLC through RS485 connector. The system use WINDOWS2000 with soft ware IFIX |

Working Flow of Fully Automatic C&Z Purlin Roll Forming Machine

Which is Stronger: Z purlin or C purlin?

From the viewpoint of loading capacity, Z purlin is normally seen as much stronger than C purlins, as the Z steel purlins have better integrity and can be overlapped continuously. Thus, when it comes to constructing metal buildings with continuous spans, it is better to use Z purlins; whereas, regarding the building of supporting walls, C purlins will be much more favored as they can be installed and calculated more easily. As a professionalforming machine manufacturer,Hangzhou Roll Forming Technology can provide you with high-quality fully automaticCZ roll forming machinethat can produce both purlin styles to better meet your needs.

Specification ofC&Z Purlin Forming Machine

|

Machine Condition |

Fully New, A-Grade quality |

|

Panel Shape |

As profile drawing and customer’s requirements |

|

Operator |

needed 1 person |

|

Power Supply |

220V/380V/415V/460V, 50/60Hz, 3P (as requests) |

|

Equipment Weight |

About25T |

|

Dimension |

(L*W*H) about 45*3*2m |

|

LOADING SIZE |

Normally need 2x 40' container. |

|

Equipment Color |

Normally Blue/White, or as requests; |

|

Place of Origin |

Zhejiang, China (Mainland) |

在线联系供应商

Other supplier products

| Coil Upender | Thecoil upender is used for 90-degree rollover of steel coil. Thesteel coil upender consists of a base, turntable, roller shaft group system, trans... | |

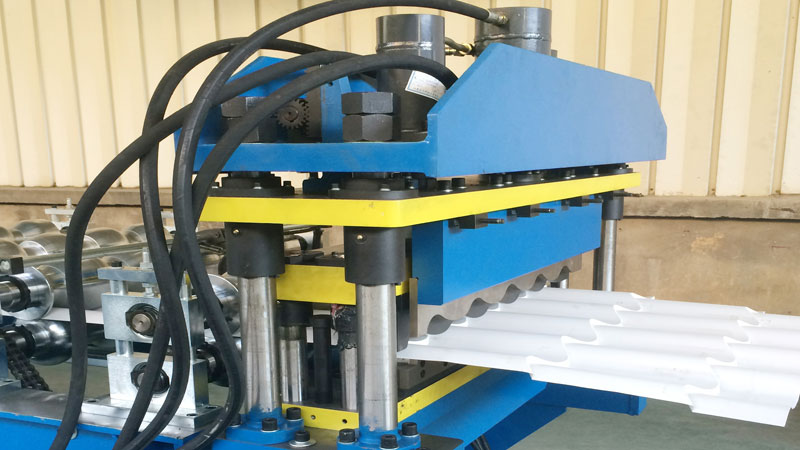

| Metal Deck Roll Forming Machine | The metal deck roll forming lineis a steel structure building material produced by cold roll forming, which is used for supporting floor concrete i... | |

| HIGH SPEED ROOFING TILE MAKING MACHINE | The high-speed metal roof tile machineis for continuously roll forming and pressing step tiles sheets. The step length of this series can be set up... | |

| Roof And Wall Panel Roll Forming Machine | The cold roll forming machine is the equipment for continuously processing metal sheets of a coil, a strip, by a multi-pass forming roller which is... | |

| Cut To Length Line | Function of Cut To Length Line It is used for cutting steel coils into certain length sheets. Technical parameter of decoiling machine cut to l... |

Same products

| Micronized polypropylene wax for injection moulding | 卖方: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | 卖方: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |