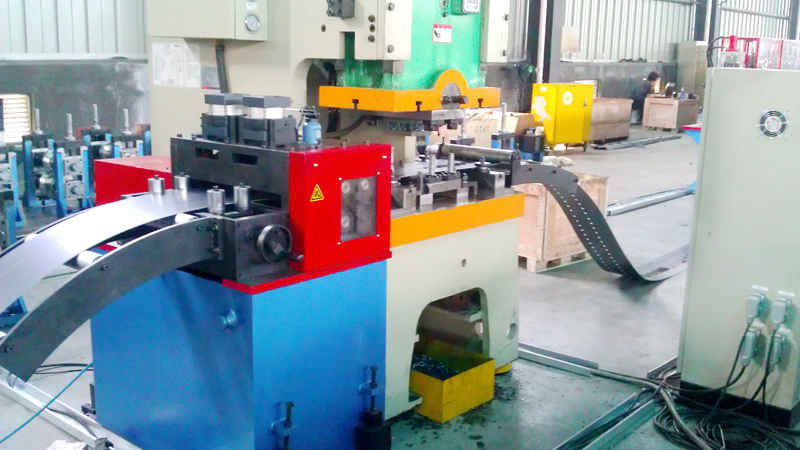

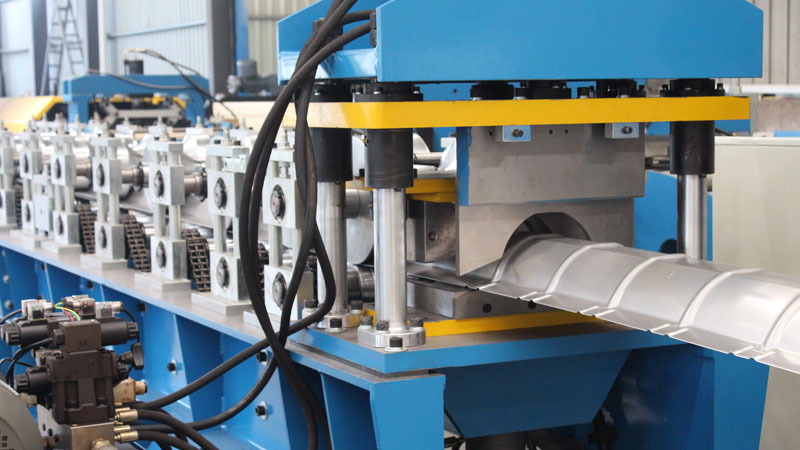

Heavy Duty Shelf Column Roll Forming Machine

Our heavy-duty shelf column roll forming machine has been widely used in the production of city shelves, storage shelves, super heavy shelves, and other profiles of cold roll forming. Adopting industrial control PLC and man-machine operation interface, thisheavy plate rolling machinecan effectivelyrealize production automation. By inputting parameters such as hole spacing, product length and quantity, punching, molding, and cutting can be completed at one time during production.

Able to conduct continuous production without shutdown, theseheavy plate rolling machines can ensure stable product quality with accurate sizes. With the help of machines in this series, you can not only lower the production cost of your shelf column roll racks but also greatly improve the working efficiency. In short, with multiple functions, ourheavy plate rolling machines can be combined with different production needs so as to make the enterprises in the fierce market competition become more competitive.

Features and Advantages of Heavy Duty Shelf Column Roll Forming Machine

Cassette-type platform and quick-change machine base formulti-profile purposesare available for choice.

Both underground pit and overground accumulating devices are available for further selections.

Ground pit/overground accumulating unit, non-stop hole punching unit, and flying tracking cutting and automatic stacking devices are available for the choice to improve production speed greatly.

With a non-stop punching, flying cutting system, this heavy plate rolling machine can reach the production speed of 30m/min.

Patents under both CECertified and EUROPEANquality standards

Ready heavy plate rolling machines in stock for prompt delivery.·

Suitable Coil Sheet Material forHeavy Duty Shelf Column Roll Forming Machine

Suitable material: Cold/hot Rolled Steel, Galvanized Steel

Thickness: 1.0-2.0 (mm)

Yield Strength: 230-300 (MPa)

Width: As profile requests

Production Line Components and Parameters ofHeavy Duty Shelf Column Roll Forming Machine

|

Decoile |

3T/5T/8T |

|

Leveling device |

|

|

Underground pit/ overground accumulating unit |

optional |

|

Servo Feeding Device |

|

|

Holes punching device |

|

|

Ground pit/ overground accumulating unit |

optional |

|

Guiding device |

|

|

Roll forming system |

10-30m/min (adjustable) |

|

Post cutting device |

flying cutting, tracking cutting and stop to cut are available for choice |

|

Output System |

Manual supporter/ Auto Stacker (optional) |

|

Auto Stacker |

(Output direction) Lateral/Longitudinal (optional) |

|

Hydraulic system |

Power supply for holes punching /post-cutting system |

|

Electric control system |

MITSUBISH/ SIEMENSE/AMS/Omron (optional or as requested ) |

Working Flow ofHeavy Duty Shelf Column Roll Forming Machine

Decoiler - Leveling device - Ground pit/ overground accumulating unit (optional) - Servo feeding device - Hole punching device - Ground pit/ overground accumulating unit (optional) - Guiding unit - Roll Forming System - Post-Cutting to length(flying cutting, tracking cutting, and stop to cut are available for choice)

Rack Profile Drawings

Finished Panels byHeavy Duty Shelf Column Roll Forming Machine

Specification ofHeavy Duty Shelf Column Roll Forming Machine

|

Machine Condition |

Fully New, A Grade quality |

|

Panel Shape |

As profile drawing and customer’s requirements |

|

Operator needed |

1 person |

|

Power Supply |

220V/380V/415V/460V, 50/60Hz, 3P (as requests) |

|

Equipment Weight |

about10-20T |

|

Dimension |

(L*W*H) about 30*3*2m |

|

LOADING SIZE |

Normally need 2 x 40' container |

|

Equipment Color |

normally Blue/White, or as requests |

|

Place of Origin |

Zhejiang, China (Mainland) |

|

Packing |

Standard and careful export packing |

Our company, Hangzhou Roll Forming Technology Co, Ltd, has engaged in desingning and manufacturing roll forming, coil processing equipment and tube/pipe mill for 17 years. We provide roll forming production line, tube mill machineand etc.

在线联系供应商

Other supplier products

| Downspout Elbow Machine | The series of elbow forming machines are mainly used to bend A and B style elbow downspouts. Aiming to meet the needs of different occasions, this ... | |

| High Speed Double Deck Roll Forming Machine | Features and advantages of High Speed Double Deck Roll Forming Machine With 2 layers of guiding tables, roll forming and cutting to length systems... | |

| Hydraulic Shearing Machine | 1. According to the shape of the scissors, the shearing machines are divided into straight knife shears and disc knife shears. Straight knife shear... | |

| Ridge Cap Roll Forming Machine | ridge cap machineIntroduction This machine is used to make ridge capping. Ridge capping is a critical part of the structure of a roof. Ridge cappi... | |

| CNC FOLDER | Hangzhou Roll Forming Technology, a professional CNC folding machine supplier, has high-quality sheet metal cnc folder for sale. The numerical cont... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |