CNC Die Sinker EDM Machine For Sale

CNC Die Sinker EDM Machine For Sale

As a professional CNC Die Sinker EDM Machine manufacturer, we aim at providing you erosion machines with high quality. EDM sinker for saleis waiting for your contact with a warm welcome. We are available if you have any questions about spark erosion machine for sale.

What is CNC Die Sinker EDM Machine?

CNC die sinker EDM machine refers to a machine that can realize the discharge machining or the multi-axis dynamic discharge machining. The mechanical structure of the sinker EDM machine is firm and strong with a practical function. Sinker EDM machine is perfect machining applied in the tooling industry for it can produce molds with high precision and smoothness. EDM die sinking machine is wildly used in any industry which requires a precision finish. Due to the hard property of metal, the spark erosion machine only comes out with the electrical sparks rather than touches the metal directly.

Die Sinking EDM Operation

Die sinking EDM is carried out in a liquid medium. The automatic device of the EMD die sinking machine keeps a proper discharge gap between the workpiece and the tool electrode. When a strong pulse voltage is applied, the dielectric insulation strength is at the lowest point. Because the discharge area of the CNC EDM spark machine is very small and the discharge time is very short, the energy is highly concentrated, so that the temperature is as high as ℃. Then the metal is thrown into the working fluid. And the shape of the sinker EDM machine electrode is reproduced on the workpiece.

Types of CNC Sinker/Sinking EDM Machine For Sale

Windows Platform CNC EDM Machine

As a type of EDM CNC electric discharge machine, ADI series high precision CNC EDM die sinking machine has the latest DMNC's 6th generation Windows platform control system, upgraded mechanical structure with better accuracy, three years casting aging treatment, SP grade linear guideway and C2 grade ball screw, new designed optimized mechanical structure, all upgradations make ADI series the right choice for present and future demands in high accuracy CNC EDM machine technology. The latest control system has high scalability to make up-gradation in the future is quite easy, lifelong up-gradation is available.

Automation CNC EDM Machine

ADV series new generation CNC EDM spark erosion machine is designed for automation, there are many different flexible options. Equipped with a robot and electrode and workpiece store, EDM CNC automatic machine itself can realize small parts, large quantity, and man-free production, for this solution, before production starts, the operator needs to set electrodes and workpiece. Furthermore, the CNC milling center of electrode and CMM can be brought in to realize full automation from electrode machining, electrode checking, spark erosion machining, product checking and etc. The cost of labor cost is increasing rapidly recently, to release the pressure of labor cost and increase efficiency, automation application in EDM machining industry is born for the future.

VIEW MORE

CNC EDM Sinker Machine C Structure A30, A45

CNC EDM Sinker Machine C Structure A30, A45

“C" structure CNC EDM machine A30 and A45 are equipped with a 5th generation electric discharging machining control system, which has excellent machining performance of both copper electrodes and graphite electrodes. With excellent performance, the EDM CNC die sinker machines are suitable for processing small and medium-sized precision plastics and die-casting molds, especially for cosmetics molds, high-end toy molds, molds of medical products, carbide machining and other industries. Welcome to contact us if you need any kind of CNC EDM die sinker spark erosion for sale!

Ram Type CNC EDM Machine with Fixed Table

This type of EDM machines are usually big for heavy loading, therefore, we call them large CNC EDM machines, the structure has a fixed working table, the motion of X, Y, and Z-axis are all located on the saddle side. Because the weight of the workpiece is not giving gravity on moving axes, so when the workpiece comes very heavy, there is no influence of moving parts, the ideal of heavy molds machining.

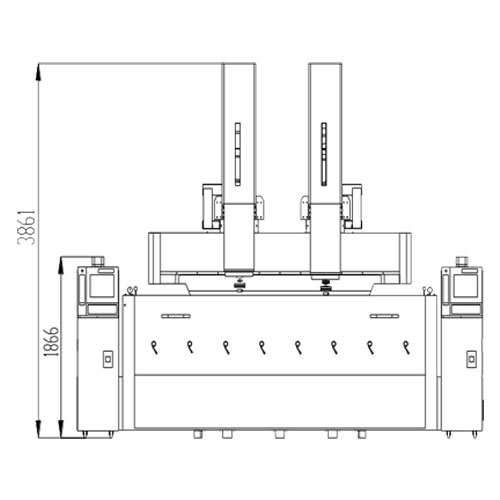

Double Heads Large CNC EDM Machine

Twin-head large EDM CNC sparking machine has two separated spindle heads and two separated controllers, also called double column CNC EDM machine, it was developed for some kinds of molds with very large size. Max table size could be up to 3500mm, and load capacity up to 20000kgs. Besides, two separated CNC electric discharge machines could be performed at the same on different locations of one mold. Of course, the dynamic and mechanical of double head CNC EDM is not as good as single-head CNC EDM die sinking EDM machine.

General Purpose CNC EDM Machine P40

P40 CNC EDM machine has three axis simultaneous control and 4th generation electrical discharging control system, best surface finish Ra≤0.12μm, Min. electrode wear ≤0.05%, standard equipped with 50A controller and Max machining efficiency ≥500mm3/min. Good performance, favorable price and suitable dimension make P40 the good choice for starting the business in the field.

Main Dimensions of General Purpose CNC EDM Machine P40

X×Y×Z travel: 400×300×320mm;

Working table dimension: 700×400mm;

Working tank on the table: 1200×680×440mm

ZNC Die Sinking EDM Machine

ZNC electrical discharge machining machine is the traditional type with X and Y-axis manual control, usually, the operator needs to manually move the working table to the location of where to do spark eroding on the workpiece. Z-axis is automatically controlled by servo motor, operation of ZNC EDM spark erosion machine is simple compared to CNC die-sinking EDM. Due to the limitation of no control of the X and Y axis, the ZNC EDM spark erosion machine can't do simultaneous orbital machining, even use an orbital cutting head, the result of accuracy and surface is not as good as what can achieve on CNC EDM machines. But thinking about the cost of ZNC EDM, it's ideal for the start or jobs without a strict requirement of accuracy and surface finish. Contact us to get our ZNC EDM spark erosion machine price now!

BIEM is one of the key edm parts supplier in china, we provide cnc sparking machine, high speed small hole drilling edm, electrical discharge machine for saleand etc. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| CNC EDM Hole Drilling Machine for Sale | CNC EDM drill, also known as CNC EDM small hole edm drilling machine, basically, there are three axis control(X, Y, Z), 4-axis control(X, Y, Z and ... | |

| General Purpose CNC EDM Wire Cut Machine F Structure | CNC Die Sinking/Sinker EDM Machine, also known as CNC die-sinking EDM electrical discharge machine and CNC Spark Erosion Machine provided by one of... | |

| ZNC Die Sinking EDM Machine | CNC wire cut EDM, which is a kind of spark erosion machine or electrical discharging machine, utilizes electrode wire (normally molybdenum wire or ... | |

| A1880 Double Heads CNC RAM EDM Machine | A1880 twin heads CNC spark erosion machine has two separated controllers and two separated machine heads, three axis simultaneous control of each h... | |

| A1880 Double Heads CNC RAM EDM Machine | A1880twin heads CNC spark edm machinehas two separated controllers and two separated machine heads, three axis simultaneous control of each head an... |