Die Casting

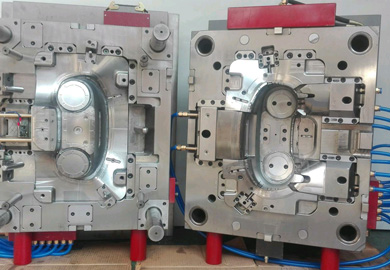

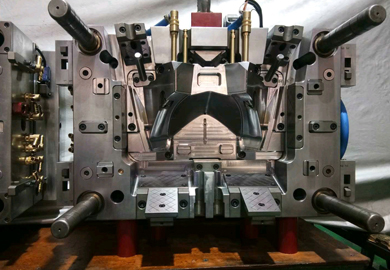

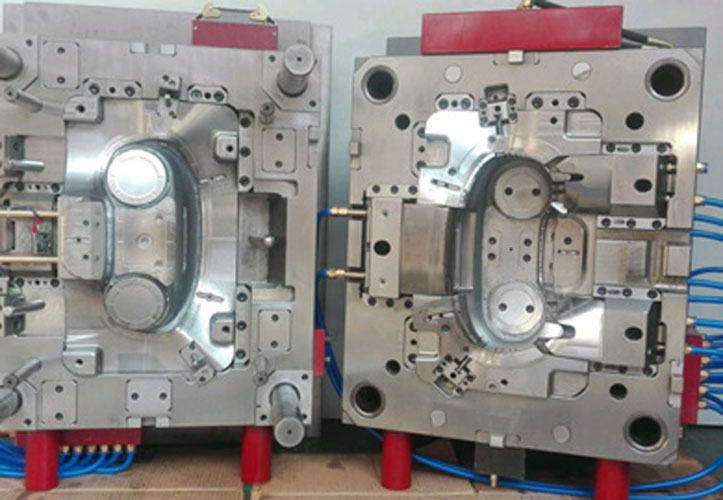

We are a plastic injection manufacturer. In the spirit of a "one-stop-shop", our own tool workshop as well as an assembly and an international sales service. We have an precision injection moldingprocess with a component load capacity of up to 2 kg in a large machine, carrying out assembly of complex component modules and offer painting and other finishing services all accompanied by the most sophisticated of logistics processes.

Aluminum dies castings are all around us. Aluminum is the most common element used in custom die casting. Aluminum dies castings are primarily used in the automotive industry for components in your car. (think engine block and transmission housing). Other uses include heat sinks, handles, valve bodies, light fixtures, and many others.

The benefits of aluminum as a cast material of automotive die castingare as follows: Lightweight, High strength, High melting temperature, Corrosion resistance, Electrical shielding properties, Good thermal conductivity, Recyclable etc. Commonly used materials for die casting productsare zinc alloys, aluminum alloys, magnesium alloys, and copper alloys.

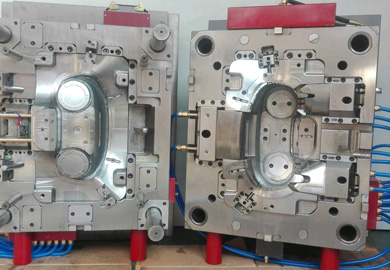

GM-TECH also focuses on the mold design service and manufacture of magnesium alloy and aluminum alloy parts, mainly including: magnesium alloy die casting china, aluminum alloy die casting, precision magnesium alloy die-casting mold, precision aluminum alloy die-casting mold, electric vehicle accessories die-casting, LED lamp accessories die-casting, sports equipment accessories, photography equipment accessories, photography tripod die-casting, projection equipment accessories, children's car accessories, motorcycles Mechanical parts and other series of products.

As a professional die casting supplierand die casting manufacturer, we provide many high quality products by our own die casting factory.

Die Casting FAQs

Is your company familiar with export mould standard?

Yes, as a professional custom injection molding company, we are very familiar with DME, HASCO and Mishmi standards.

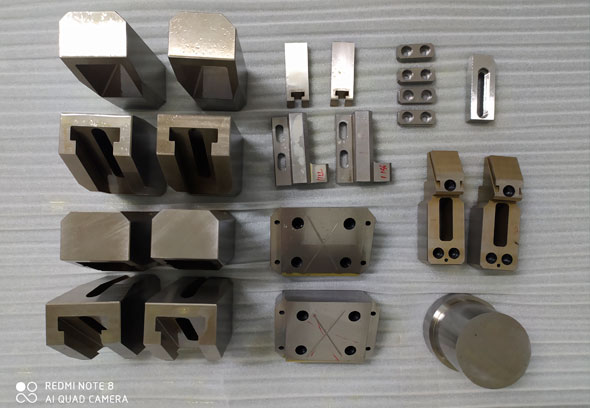

What are your common mold steel?

Generally, we use steel materials required by customers, such as 1.1343, H-13, S136, NAK80, P20 and so on. And we will provide steel certification to customers.

How do you guarantee the quality of the mould?

Mold design: when the design is completed, our engineers will meet to review the mold. Mold processing: CMM inspection will be carried out for each machining step (electrode, CNC,) of parts .

How long is the delivery time for mold processing?

specific to see the difficulty of mold, generally 2-8 weeks

在线联系供应商

Other supplier products

| Mould Slide | Mould Slide The mould slideris a mold component that can slide in a certain angle perpendicular to or with the opening and closing direction dur... | |

| Electronics Product Mould | Electronics Product Mould Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding pr... | |

| Mould Spare Part | Plastic molded productsinclude single section shoot, double section shoot, double section shoot, flat tip, flat tip, positioning column, plastic mo... | |

| 2K Mould | GM-TECH, injection moulding manufacturers,has been manufacturing tools for injection molding of plastics for various industries for more than 10 ye... | |

| Multi Cavity Mould | A multi cavity moldis known as a mould with multiple cavities. The multi-cavity mold consists of a multi-cavity of different plastic parts. Thou... |