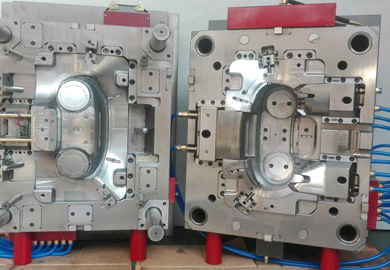

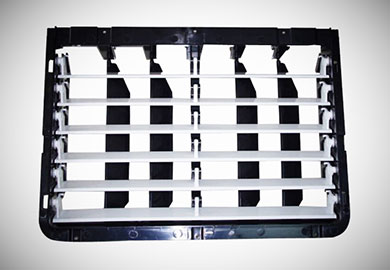

Die Casting Mould

We are a plastic injection manufacturer. In the spirit of a "one-stop-shop", our own tool workshop as well as an assembly and an international sales service. We have an precision injection moldingprocess with a component load capacity of up to 2 kg in a large machine, carrying out assembly of complex component modules and offer painting and other finishing services all accompanied by the most sophisticated of logistics processes.

Die casting mould is a method of casting liquid die forging. It is a process completed in a special die casting moulding machine.

The major advantage of mould die castingis that thousands of castings can be produced quickly by die casting mould manufacturerthrough one mould. All mould components and parts of die castings are manufactured in mass mount at relatively low unit costs.

Features of Die Casting Mould

Die casting mound technology offers many outstanding features which include:

High corrosion resistance

High strength and hardness

High thermal conductivity

High electrical conductivity

Good processing properties

As one of the die castingmould supplier, GM-TECH provides you with CNC or ultrasonic removal of the part nozzle, rotary hole, tapping, and so on. Since there are many benefits of the die casting mould, please do not hesitate to contact us if you are interested in our products.

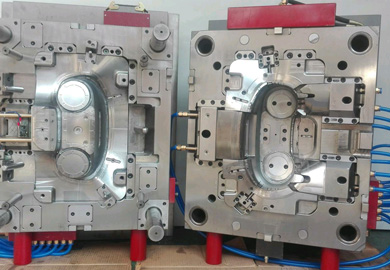

Specification of Die Casting Mould

|

Part material |

zinc alloy |

|

Cavity |

1 |

|

Mould steel |

H 13 |

|

Mould steel |

|

|

Mould life |

10W |

|

Mould standard |

HASCO |

|

Mould structure |

direct ejection |

|

Exporting country |

Russia |

|

Leadtime |

5 weeks |

|

Mould quality customer satisfaction |

99% |

|

FAI pass rate |

99% |

|

Project cooperation service customer satisfaction |

98% |

How does Die Casting Mould Work?

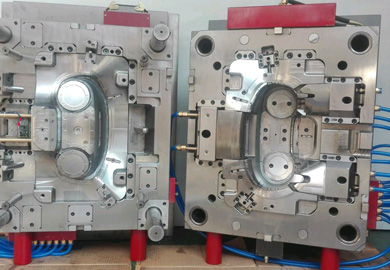

The basic working process of the die casting mouldcnc componentsis as follows. The liquid metal first low speed or high-speed casting filling mold into the mold cavity. The die casting mould has an active cavity surface with the cooling process of the liquid metal pressure forging.

It not only eliminates the blank shrinkage cavity shrinkage porosity defects but also makes the blank internal organization reach the forged state of broken grains. The comprehensive mechanical properties of the blank are remarkably improved.

在线联系供应商

Other supplier products

| Mould Design | GM-TECH have a much experienced design team, familiar with China domestic, European, American, Japanese and other mold design standards, be able to... | |

| Mould Base | Mould Base After years of development, mold base production industry has been quite mature. Injection molding manufacturers can purchase custom... | |

| 2K Mould | 2k mouldingis a manufacturing process that refers to molding two materials or colors into one plastic part. This technology combines two materia... | |

| Home Appliance Part | Home Appliance Part The development and design of plastic injection molding home appliance parts pay attention to safety and health. In-home appli... | |

| Die Casting Mould | Die casting mould is a method of casting liquid die forging. It is a process completed in a special die casting moulding machine. The major adva... |