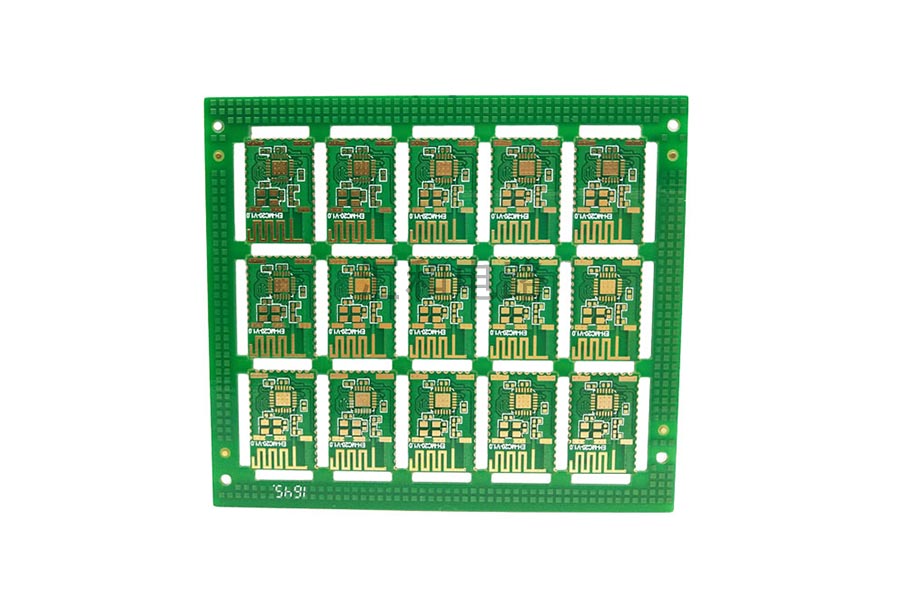

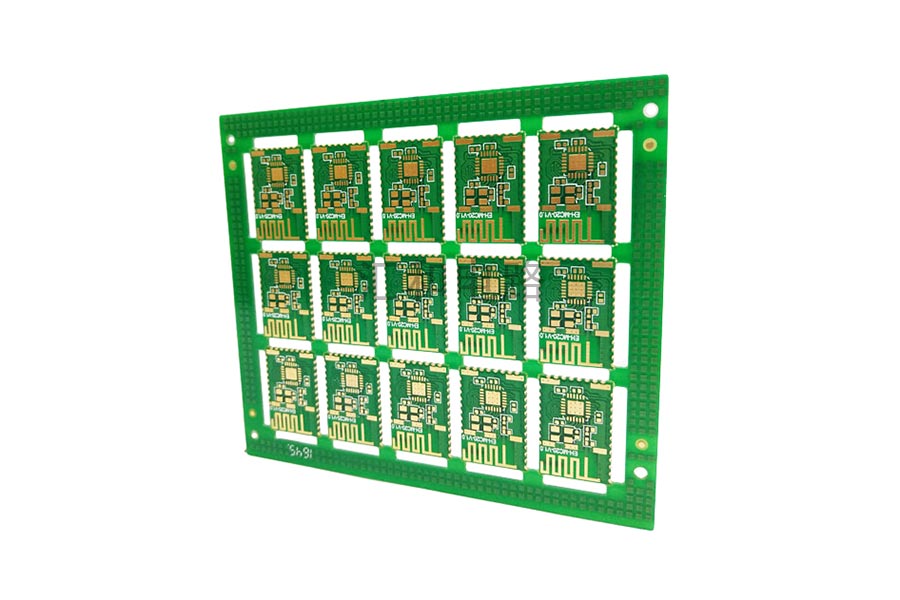

PCB Board

As aprofessionalpcb manufacturing company, HUIHE Circuits has mastered advanced technology in the PCBindustry, we own reliable production equipment, test machine and fully functional P&C lab. Our products include 2-28 layers, high TG, heavy copper, high frequency, mixed-dielectric laminate and buried & blind via board.

With the help of a technology development team for professional pcb manufacturing, HUIHE Circuits has mastered advanced technology in the PCB industry, we own reliable production equipment, test machine and fully functional P&C lab. Our products include 2-28 layers, high TG, heavy copper, high frequency, mixed-dielectric laminate and buried & blind via board.

What Is PCB

Printed circuit boards for saleis one of the important parts of the electronics industry. Almost every kind of electronic equipment, from electronic watches to computers and military weapon systems, as long as there are electronic components such as pcb printed circuit, small printed circuit board and large printed circuit board must be used in order to make electrical interconnections between the various components.

The blank copper pcb board and electrical pcb board has good product consistency, and it can adopt standardized design, which is conducive to the realization of mechanization and automation in the production process.

The reason why PCB can be used more and more widely is because it has many unique advantages, which are roughly as follows:

High-density

Over the years, the high density of printed boards/blue pcb board has been able to develop correspondingly with the improvement of integrated circuit integration and the advancement of mounting technology.

Testability

A relatively complete test method and test standard have been established. Various test equipment and instruments can be used to detect and appraise the eligibility and service life of PCB products.

Maintainability

Since PCB products and various components are assembled in a standardized design and large-scale production, these components are also standardized. Therefore, once the system fails, it can be replaced quickly, conveniently and flexibly, and the system can be quickly restored to work.

High reliability

Through a series of inspections, tests and aging tests and other technical means, the PCB can be guaranteed to work reliably for a long time.

Assemblability

PCB products are not only convenient for standardized assembly of various components, but also for automated and large-scale mass production. In addition, by assembling the PCB and various other components as a whole, larger parts and systems can be formed to the complete machine.

What Are PCB Board Made Of?

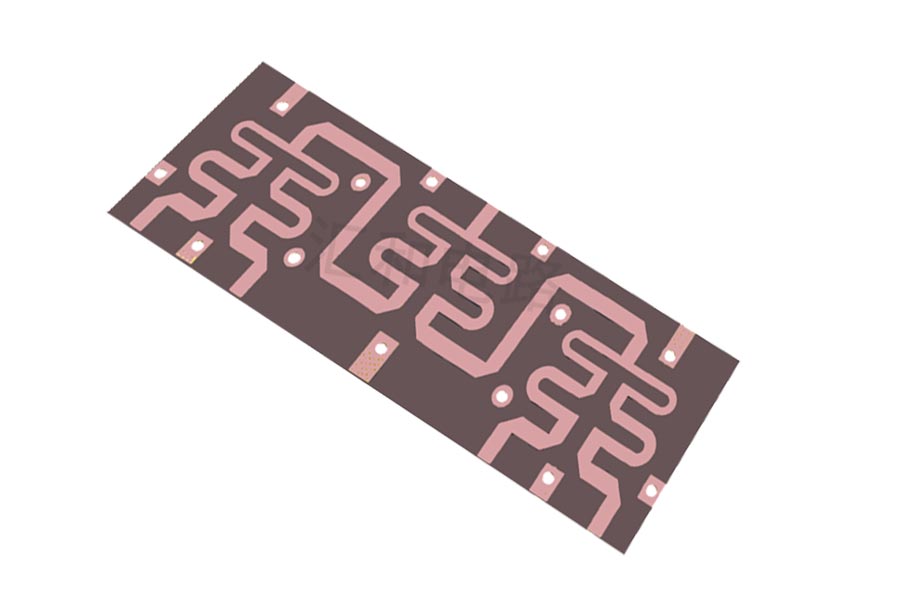

Substrate

Insulating laminate composed of polymer synthetic resin and reinforcing material can be used as the substrate of copper clad laminate. There are many kinds of synthetic resins, commonly used are phenolic resin, epoxy resin, polytetrafluoroethylene and so on. Reinforcement materials generally have two types: paper and cloth, which determine the mechanical properties of the substrate, such as solder dip resistance and bending strength. According to raw materials, there are usually

lPaper substrate: a. The blue HB is a non-repellent fuel; b. The red HB is a fuel-repellent fire rating of 94v0.

lSemi-glass fiber material: a, 22F b, CEM-1 c, CEM-3, also known as imitation FRA

lFull glass fiber material: What is the inner fiber content of FR1, 2, 3, 4, and FR4 is commonly used.

The key material for the manufacture of copper-clad plates must have high conductivity and good weldability. According to ministerial standards, the nominal series of copper foil thickness are 18, 25, 35, 70 and 105um. my country is currently gradually promoting the use of 35um thick copper foil. The thinner the copper foil, the easier it is to etch and drill, which is especially suitable for manufacturing high-density printed boards with complex circuits.

Claim:

lThere must be no scratches, sand holes and wrinkles on the surface of the copper foil

lMetal purity is not less than 99.8%

lThe thickness error is not more than ±5um

Requirements

The adhesive is an important factor in whether the copper foil can be firmly covered on the substrate. The peel strength of the copper clad laminate mainly depends on the performance of the adhesive. 4. Board thickness: usually refers to the requirements of the finished product, respectively, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.6mm, etc

If you want to know blank pcb board price, please contact us.

在线联系供应商

Other supplier products

| 2 Layer F4B ENIG PCB | Number of layers: 2 Surface finish: ENIG Base material: F4B Outer Layer W: 6mil Outer layer S: 6mil Thickness: 1.0mm Advantages Of 2 Layer F4... | |

| New Energy PCB | As aprofessionalpcb manufacturing company, HUIHE Circuits has mastered advanced technology in the PCBindustry, we own reliable production equipment... | |

| PCB Application | As aprofessionalpcb manufacturing company, HUIHE Circuits has mastered advanced technology in the PCBindustry, we own reliable production equipment... | |

| 2 Layer ENIG Half Hole PCB | Number of layers: 2 Surface finish: ENIG Base material: FR4 Outer Layer W/S: 8.5/3.5mil Thickness: 0.8mm Special process: half hole Advanta... | |

| 2 Layer ENIG Impedance Control Half Hole PCB | Advantages of 2 layer pcb board Own lamination process to convenient production for Multilayer PCB and shorten the lead time. Jiangxi facility is... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |