C Z Purlin Roll Forming Machine

The c&z purlin forming machine, also calledC Z purlin China roll formerC Z purlin making machine. This type of C Z China forming machinecan change the profile and specifications automatically without replacing the rollers if want to do different purlines with different specifications, and there is a screen showing the changes. In mass production, the PLC can control the profile, specification, length, vertical punching, cutting, and roll forming automatically.This C Z purlin machine, purlin machineChina can form the hot/cold rolled steel coil to get various specification purlins. The C-shapeZ-shape and specification modification can be shifted automatically. The forming speed can reach 30m/min, and it's ideal equipment for the steel structure industry. The thickness range of products depends on different material, normally we can achieve 1.6-3.2mm.

Jinggong is one of the TOP Chinapurlin roll forming machine manufacturers, contact us and get C Z purlin machine price!

Types of JinggongCZ Purlin Roll Forming Machine for Sale

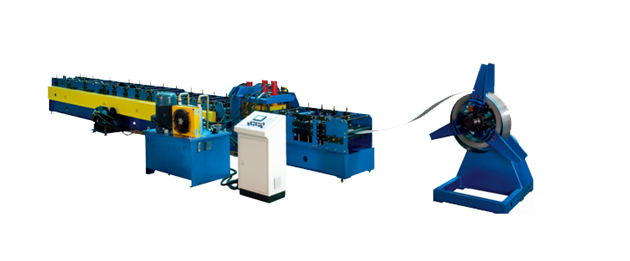

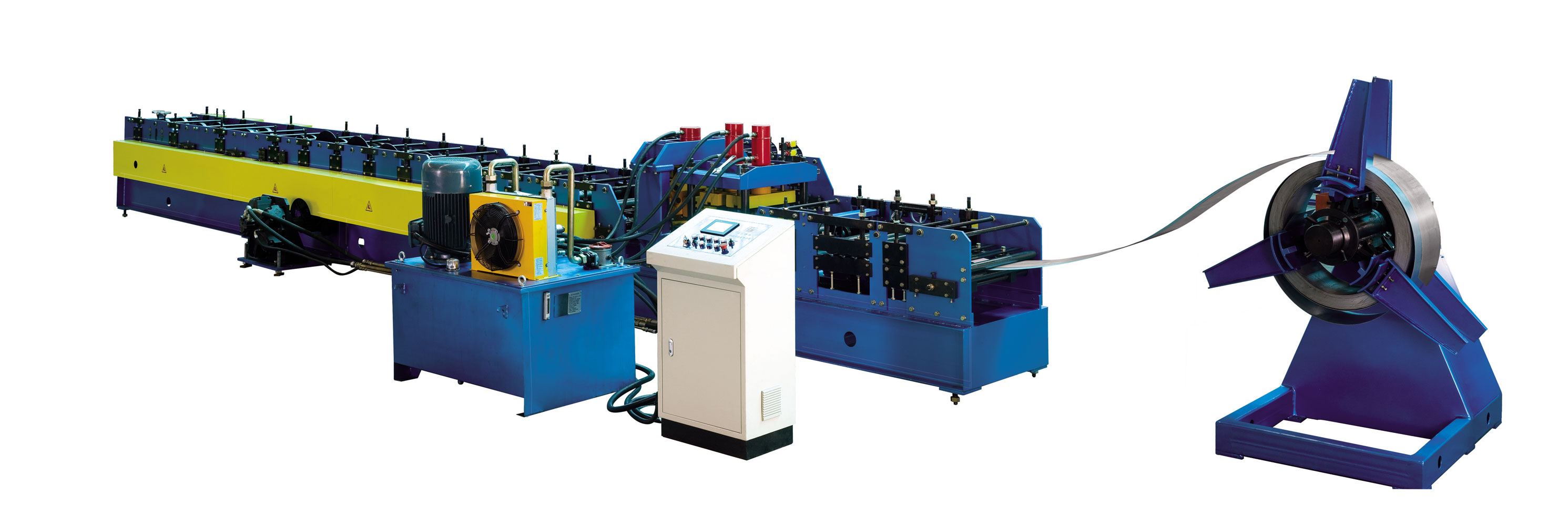

C/Z Purlin Roll Forming Machine

This machine can form hot/cold rolled metal strip through leveling, cold roll forming, punching and cutting off to produce C type or Z type purlin. Various specifications of purlin can be produced by changing the spacers.

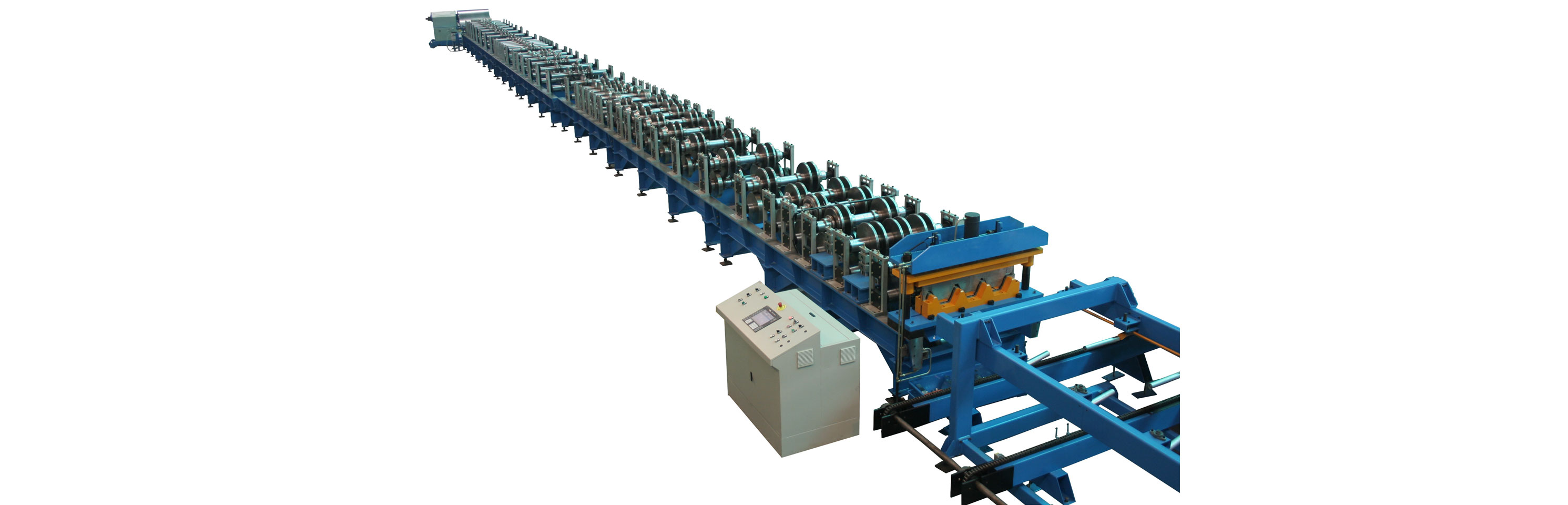

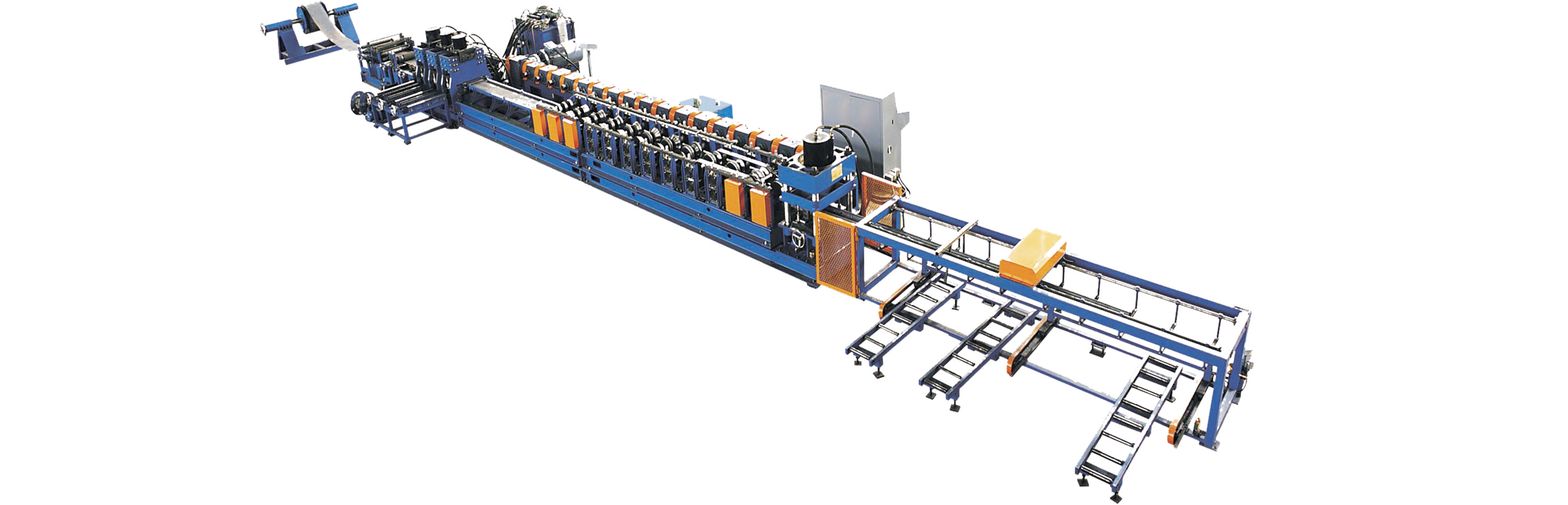

CZ Changeable Purlin Forming Machine

CZ changeable purlin machine can produce both C channel and Z change profiles in one machine, and the machine can change the profile and specifications automatically, while without replace the rollers if want to do different purlines with different specifications. And there is screen showing the changes.

Video of CZ Purlin Roll Forming Machine

C/Z changeable purlin automatic machine can produce both c-shaped steel purlin and z-shaped steel purlin in one machine quickly. And the machine can auto-change the profile and specifications automatically. The c-shaped steel purlin has good flatness, anti-bending, and anti-pressing property. The z-shaped steel purlin can reverse install that can increase the structural efficiency of the connecting point, decrease the thickness of the used steel, shorten the construction cycle, and add the benefit. They can be used as the main supporting structure and are widely used in large and medium scale factory buildings and civil constructions.

The C/Z automatic changeable purlin machine manufactured by Zhejiang Jinggong Science and Technology Co., Ltd.changes the situation of using two different machines to produce, and manually changing specifications. This machine can produce different specifications of purlin automatically. It was known for its safe and high-efficiency workflow.

The conversion and specification transformation of the CZ interchange purlin production line can be completed by automatic adjustment. It completely changes the simple processing methods that use two different types of equipment: C purlin machine and Z purlin machine.

The production process adopts automatic control mode, which can automatically complete punching, cutting, and roll forming according to the input purling length, longitudinal hole distance, quantity, and other parameters. The punching device can customize different holes according to customers' requirements, which adopt multi-station hydraulic control. And the main hydraulic valve adopts Bosch Rexroth. The cutting device adopts an arc design with full cutting and half cutting. The main drive adopts an acceleration motor and frequency conversion control. It is accurate and reliable for speed control, length fixed, and positioning control. The roll forming machine adopts fast conversion and transfers shift of magnetic red ruler with accurate purlin size, angle, and straightness. The whole line is communicated by the Mitsubishi frequency converter, plc, and touch screen through the rs-422 interface and programmable controller. All components are organically combined to form a complete control system with the advantages of simple structure, beautiful interface, reliable performance, convenient operation, high production efficiency, and so on.

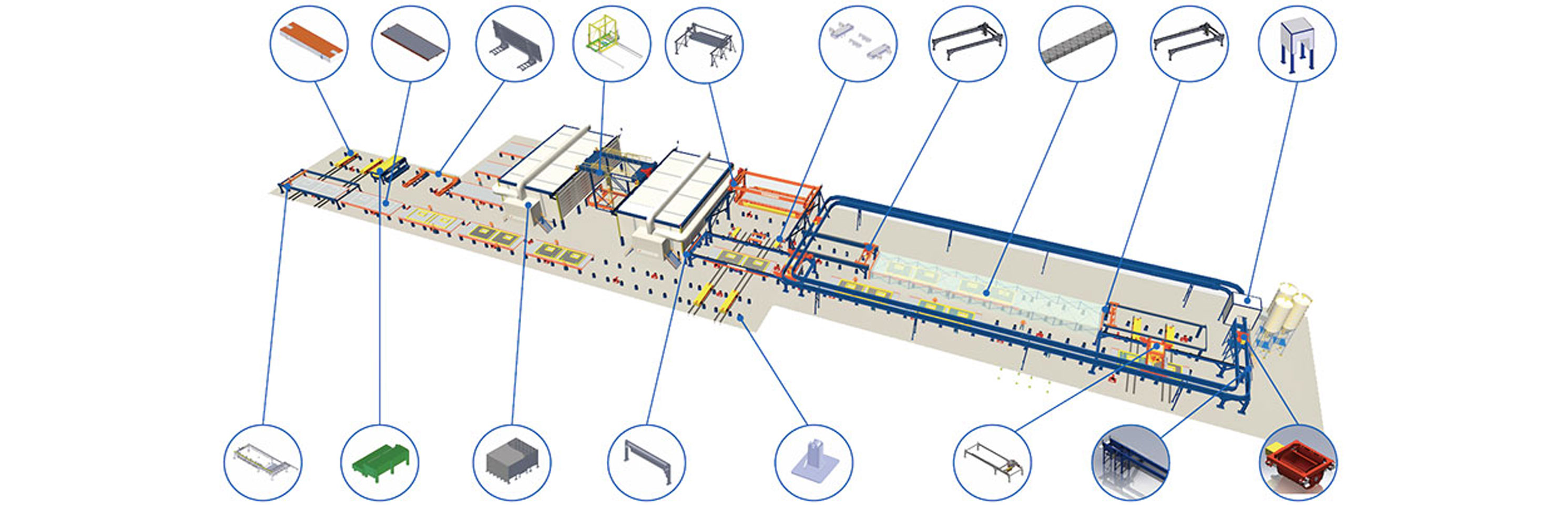

CZ Purlin Roll Forming Machine Components

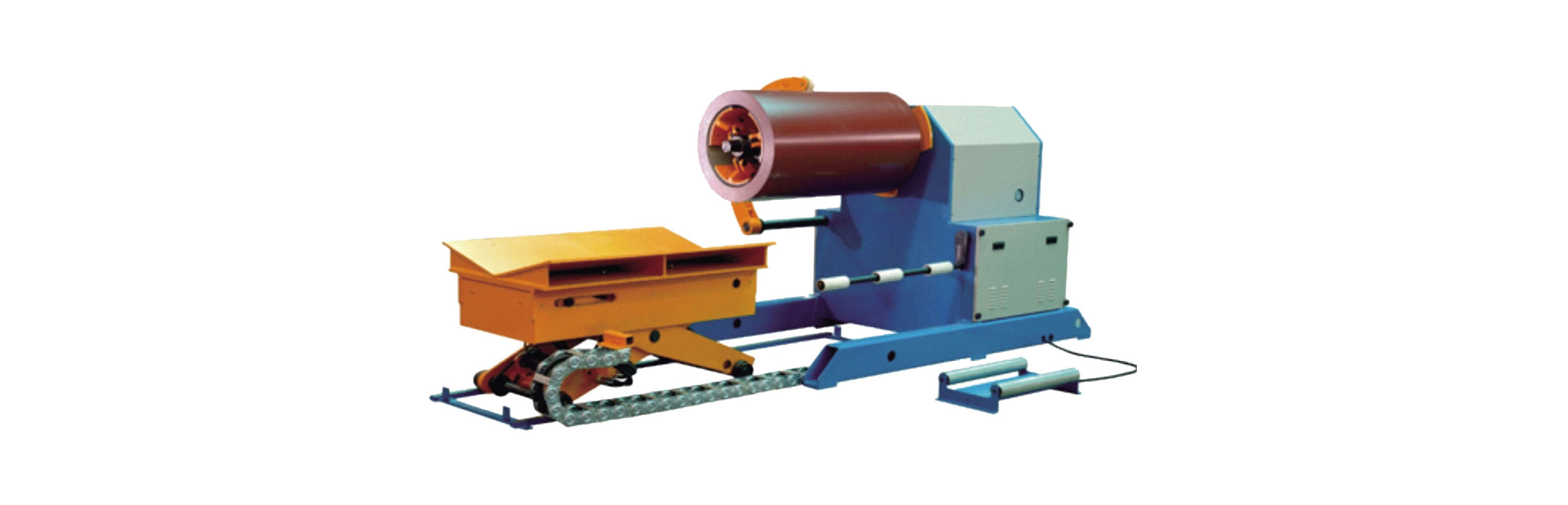

Hydraulic uncoiler

The machine adopts decoiler tighten and loosen of the steel welding structure,make the decoiler steel has some tension by brake apparatus. Besides, in order to avoid coil loosen,the decoiler opens by the sway pressure arm of the cylinder.

Leveling device

It consists of a feeding device, coil guiding roller, two sides adjustable guiding device, and leveling rollers.It is under the power of the hydraulic motor. And meanwhile,use the synchronous system to keep the leveling speed the same as the roll forming speed.

Hydraulic punching equipment

It adopts a hydraulic punching device of gantry-type frame to punching randomly around the longitudinal direction.

The punching distance in width way is 45 to 500 millimeters.

Hydraulic cutting equipment (Pre-cutting)

It can cut the panel according to the set length. Its max. coil thickness is 3.2mm and max. coil width is 620mm.

Changeable purlin roll former

Auto changeable equipment is achieved by three reducers through trains and sprockets, under 100 degrees of the fixed rotors,and lock with cylinder. Its max roll forming speed is 30 meters per minute.

Finished products stacker

Electric control system

Besides achieving the whole line automatic production, active and stable alarming devices can ensure safe and stable working of the whole line.

The whole line drive adopts ratio servo control technology with correct speed, length, and position setting, and it has an overload self-protection function.

Hydraulic system

Hydraulic system is to provide power to whole line, main function is to supply power to flattening rotor,</p><p>punching equipment, cutting, and forming rotors.

在线联系供应商

Other supplier products

| Introduction of Uncoiler and Its Functions and Features | 2020-12-29 Uncoileris special equipment for sheet metal leveling. It is applied to the leveling line of steel plates and uneven plates, which can ... | |

| Steel Deck Roll Forming Machine | The sheet produced by this steel roll forming machine has high strength with big wavelength, and adheres well to concrete. Used on tall buildings, ... | |

| Precast Concrete Panel Production Line | As the main component in precast concrete components, the assembly part, connection, combination of cast-in-place reinforced Concrete structure, PC... | |

| C/Z Purlin Roll Forming Machine | The C/Z purlin roll forming machine can form hot/cold rolled metal strip through leveling, cold roll forming, punching and cutting off to produce C... | |

| Guardrail Roll Forming Machine | Guardrail Roll Forming Machineis the special forming equipment for producing the speedway guide rail. One shift every month can produce 600 tons (m... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |