BGA Rework Station

Zhuomaois one of the best bga machine manufacturersis what we called ball grid array rework station, also abbreviated as BGArs. BGA is a chip packaging technology, which is applied to improve the performance of digital products and reduce the volume of products through the ball grid array structure. All digital products through this technology will have common characteristics, that is, small volume, strong performance, low cost and powerful function. BGAmachine Chinais the exact equipment used to repair BGA chips. According to the operation requirements, we have launched different BGA rework machines that enjoy a good reputation from our clients all over the world recently.

Now, we are providing the best ball grid array rework station including manual, semi-automatic, and fully automatic BGA repair station and workstation for PCBA repairing; microfocus BGA X-Ray inspection machines, such as offline X-Ray inspection machine, online X-Ray inspection machine, 3D/CT X-Ray inspection machine; Online& offline SMD X-Ray reel counter and SMD smart storage systems, such as smart storage rack, smart storage tower, and smart storage warehouse. This diversified BGA machine for motherboard range with reasonable price and technical support enables us to help more and more EMS companies could use higher-level automation production equipment.

As one of the professional BGA Rework Station manufacturers from China, Zhuomao promises to provide the best BGA rework station machine to our customers. We have various BGA rework stations for sale with good quality. If you want to get the BGA rework station machine price list or have any other questions, please contact us as soon as possible.

FAQ of BGA Rework Station

What is BGA Rework Station?

The BGA rework station, as the name suggests, is a machine used to rework BGA. BGA is a sealed chip. If there is a bad BGA on the production line, this machine needs to be used for rework. The BGA rework station for mobile adopts an integrated design of BGA device removal, placement, alignment, and soldering. It is suitable for the repair of BGA, CSP, POP, PTH, WLESP, QFN, CHIP0201/01005, shielding frames, modules, and other components on PCBA substrates such as servers, PC motherboards, tablet computers, and smart terminals.

How does a BGA Rework Station work?

The working principle of the BGA rework station is to use artificial intelligence (AI) technology to set a good temperature curve, and through the temperature control system, to achieve high-precision inspection and monitoring of the process of disassembly, soldering, and assembly of the BGA chip rework. The high-end BGA rework system has a visual high-definition automatic alignment function. After the PCB board and BGA, images are captured and positioned by the CCD, the image processing software analyzes and automatically corrects the deviation to achieve precise alignment and placement. The repeat placement accuracy can reach ± 0.01mm. The upper heating device and the placement head realize fully automatic identification of the placement device and placement height and have the functions of fully automatic alignment, fully automatic mounting, fully automatic soldering, and fully automatic desoldering. After knowing the working principle of the rework station, you may want to bulk buy the perfectBGA rework stationfor your electronic equipment repairing. If you want to purchase at a reasonable infrared soldering station price, please contact Seamark ZM first.

How to choose a BGA rework machine?

There are somefactors that need to be considered when you want to buyBGA rework machines.

1.Type selection

Generally, there is the hot-air rework station machine and infrared/IR rework station machine. The hot air repair station obtains the heat required for reflowing BGA Solder by blowing hot air onto the circuit card. IR BGA repair station has an infrared lamp that can receive infrared light for heating BGA components to the reflux point.

The hot air rework station has been on the market for a longer time, so technicians may be more familiar with this type. Hot air systems are also generally cheaper than IR BGA rework stations. Its disadvantage is that it is difficult to shield the surrounding components. There is a noise problem. If properly designed, the IR rework station can well locally heat BGA components. The infrared station has an additional advantage, that is, the structure is not complex and easier to maintain. When selecting an IR repair station, pay attention to discrimination. It uses infrared to work, rather than infrared as a decoration.

2. Temperature control

The best BGA rework station will provide accurate, closed-loop, digitally controlled temperature. For example, the ZMR5860 BGA machineis perfect for temperature control.

3. Work area

There are two points to note. First, the size of the work area will determine how large circuit cards the rework station can handle effectively. Secondly, the install style of the slide rail. Generally, the installation guide rail is adjusted on at least one axis, but there will be multiple adjustments in the high-end SMT rework station. This will make it easier to capture and hold circuit cards with complex shapes.

Apart from these three factors, you need to find some reliable BGA rework station manufacturers. After you choose a reliable manufacturer, you should consider the BGA rework station price. To get good quality machines at a reasonable price. Contact Zhuomao immediately!

在线联系供应商

Other supplier products

| ROHS Testing Machine | CIC-D100 Ion Chromatograph for Halogen-free Detection Industry In terms of instrument analysis, ED-XRF (X-ray fluorescence spectrometer) and CIC (... | |

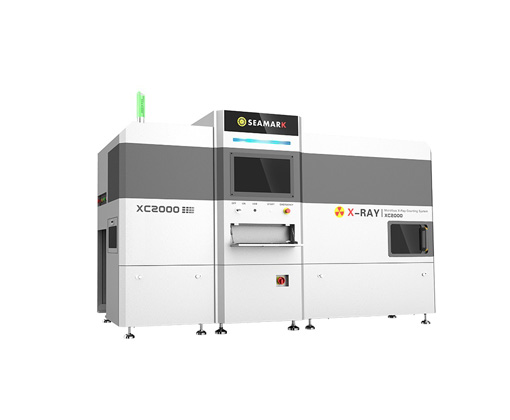

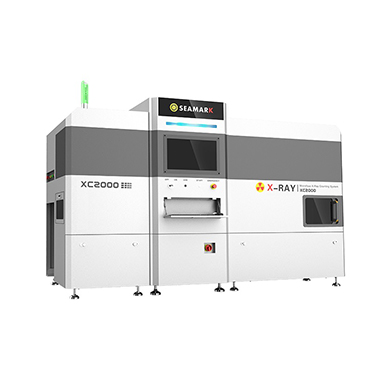

| XC2000 Inline Component Counting Equipment | XC2000 is an inline automatic counting machine. It uses the X-Ray perspective principle and the independently developed algorithm software with AI ... | |

| XC1000 Offline Reel Counter | XC1100is a micro-focus X-ray full-automatic counting machine. It uses X-Ray perspective principle and independently developed algorithm software... | |

| Online Reel Counter | Online Reel Counter X-Ray counting machine, also known as SMD components counter. The equipment adopts the principle of photoelectric sensing and ... | |

| Offline Component Counting Equipment | The offline counting machine is a micro-focus X-Ray automatic counting machine. This X-Ray counting machine uses the X-RAY perspective principle... |

Same products

| Micronized polypropylene wax for injection moulding | 卖方: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | 卖方: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |