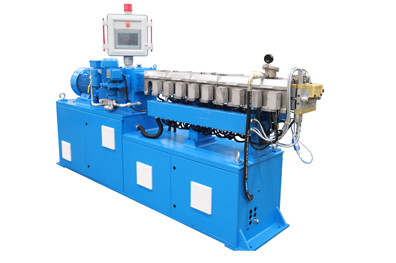

HK Series Co Rotating Twin Screw Extruder

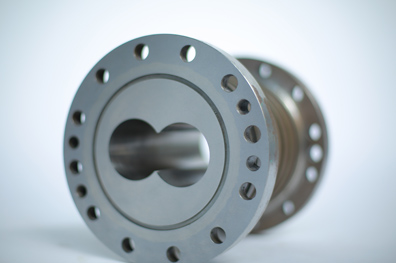

Nanjing KY provides more material selections for the process parts of the HK Series co rotating twin screw extruder. Besides standard nitriding steel and tool steel, the HIP materials made in China also provide higher wear resistance for machines. Different corrosive powder metallurgy materials are also applied to screw element and cylinder bushing manufacture, and their properties are very close to the same.

HK Extruder for Small Batch Production

HK36 and HK53 are very competitive equipment models for small batch production scale, especially for the Color Masterbatch industry.

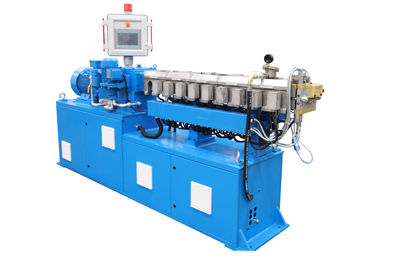

HK Extruder for Mass Production

In the field of engineering plastics and high filling, mass production and stability have always been the most concerned problem for users.

HK Large Extruder Production System

KY also offers a larger-scale HK extruder, with the commonly used screw diameters ranging from 110 mm to 165 mm (HK110-165) available for user selection.

Your Premier Twin Screw Extruder Manufacturer——KY

The process components of KY's HK co-rotating twin screw extruder Chinaseries, such as the screw and cylinder, can be interchanged with AK or SK specifications, and the geometric design of this small extruder for saleis completely consistent. This also means that customers of Nanjing KY AK or SK can seamlessly transfer the original products to newly purchased HK equipment, to achieve higher output or better return on investment.

HK Series Twin-screw extruder is a medium-high torque and high-speed co-rotating extruder launched by Nanjing KY in recent years to meet the new needs of customers. It has gained a huge market share and currently produces more than 120 extruders annually.

HK transmission system including large extruder production system based on Nanjing KY independently developed high-torque gearbox adopts the leading transmission technology in the industry, strengthens the output system of the gearbox with enhanced structure, achieves the ideal result of pure torque output with parallel biaxial output, and greatly improves the safety of gearbox. The transmission parts of our co-rotating twin pe extruder machine, small extruder machine can be manufactured by German or British torque limiter so that gearboxes and process parts can be safely protected when the torque exceeds the standard. As a mature extruder machine manufacturer, Keya would love to be your premier twin-screw extruder partner.

Difference Between Co Rotating And Counter-Rotating Twin Screw Extruder

As the names themselves suggest, while the screws of the co-rotating twin screw extruders will rotate in the same direction, the screws of the counter rotating screw extruder machine will rotate in opposite directions. As for the co-rotating extruder, there are two possible ways to rotate, either clockwise or counterclockwise. In practice, the more common one is clockwise rotation and the screw thread should be right-handed. And regarding the counter-rotating twin-screw machines, they normally use inward rotation and outward rotation.

Parameter of HK Series Co-rotating Twin Screw Extruder

|

HK Series Co-rotating Twin Screw Extruder Model |

Production Capacity kg/hr (Reference Value) |

|||||||

|

Material Process Category |

Typical Material |

HK26 |

HK36 |

HK53 |

HK63 |

HK73 |

HK96 |

HK136 |

|

Filling modification |

PE, PP, EVA, etc. + calcium carbonate, talcum powder, titanium dioxide |

5~10 |

40 ~ 80 |

130 ~ 260 |

260 ~ 460 |

500 ~ 700 |

1000 ~ 1300 |

1500 ~ 2300 |

|

ABS, PC, PS, etc. + aluminum hydroxide, magnesium hydroxide, antimony oxide |

||||||||

|

PP, PA, ABS, etc. + iron powder, magnetic powder, ceramic powder |

10 ~ 20 |

80 ~ 120 |

160 ~ 260 |

330 ~ 460 |

600 ~ 800 |

1200 ~ 1600 |

1500 ~ 2600 |

|

|

Blending modification |

PP, PE, PS + SBS; PP, PA + EPDM; PP + NBE; EVA + silicone rubber etc |

5~ 10 |

50 ~ 100 |

130 ~ 210 |

230 ~ 390 |

450 ~ 650 |

900 ~ 1400 |

1400 ~ 2600 |

|

PE, PA, PC, CPE + ABS; ABS + TPU; PBT + PET; PP + PE etc |

5~ 10 |

40 ~ 80 |

100 ~ 210 |

230 ~ 330 |

400 ~ 500 |

850 ~ 1300 |

1000 ~ 2600 |

|

|

Color masterbatch |

PE, PP, ABS, EVA, PS, etc. + pigments and other additives |

3~ 8 |

50 ~ 70 |

130 ~ 200 |

230 ~ 310 |

300 ~ 450 |

800 ~ 1000 |

800 ~ 1600 |

If you want to know more details of twin screw extruder machine price, please contact us.

在线联系供应商

Other supplier products

| KY-Lab Twin Screw Extruder | Overview of KY-Lab Twin Screw Extruder Since its establishment in 1993, KY has been devoted to the development and manufacture of small laboratory ... | |

| KY-Lab Twin Screw Extruder | Overview of KY-Lab Twin Screw Extruder Since its establishment in 1993, KY has been devoted to the development and manufacture of laboratory twin s... | |

| Barrels | The body of the basic grade barrel is made of 45 # steel. The liner of the barrel is made of basic alpha-101 bimetallic material. The high-grade... | |

| HK Extruder for Small Batch Production | HK36 and HK53 small plastic twin-screw extruders are very competitive equipment models for small batch production scale, especially for the Color M... | |

| 1twin screw extruderPlastic Extruder & Pelletizer For Masterbatch | What is Masterbatch? Masterbatch is an indispensable part of the plastic industry. It can not only give colorful plastic products, improve the val... |