SK Series Co Rotating Twin Screw Extruder

SK series double screw extruder machineis the crystallization of more than 30 years'experience in the equipment manufacturing industry, more than 400 kinds of material technology application and thousands of working conditions verification of KY. Screw diameter can be selected from 26 mm to 135 mm.

SK Series double plastic extruder Chinaadopts the welding and manufacturing process of international leading standards. It provides the best stability and reliability in operation and has successfully succeeded in replacing imported products in China.

SK26/36 Twin Screw Extruder

SK36 twin screw extruderis mainly used for experiment and small batch production, especially for small batch and multi-variety materials

SK53 Twin Screw Extruder

SK53 twin screw extruder can be used in engineering plastics, color masterbatch, functional masterbatch, blending modification and other industries.In order to adapt to the high temperature

SK63 Twin Screw Extruder

SK63 twin screw extruder can be used in filling masterbatch, engineering plastics, color masterbatch, functional masterbatch, blending modification and other industries.

SK73 Twin Screw Extruder

SK73 twin screw extruder can be used in a large number of filling masterbatch, engineering plastics, functional masterbatch, blending and modification industries.

SK96 Twin Screw Extruder

SK96 twin screw extruder can be used in single filling masterbatch, engineering plastics, polyolefin powder granulation and other industries.

SK135 Twin Screw Extruder

SK135 twin screw extruder can be used in polyolefin powder granulation and other industries, but also can be used in reactive extrusion, devolatilization and other operations.

SK Series Twin screw extruders have the following advantages:

High-efficiency transmission system

The SK Series Mini Twin screw extruder adopts the high speed and high torque transmission system of Henschel of Germany. The screw has a maximum speed of 900 rpm. and a torque of 13 Nm/cm³. The system of K Series Twin screw extruder adopts the latest design of Henshl, and the overall strength and gear system stability are greatly improved. At the same time, the system is smaller and equipped with more powerful lubrication and cooling system, which enables users to use extruders safely and quietly.

British BiBBY torque limiter with high sensitivity and reliability can effectively avoid equipment shutdown due to improper operation or accidental overload.

Siemens's global joint insurance ILE0 series inverter motor has the characteristics of high efficiency, energy-saving, safety and so on. It provides technical support and service for localization.

Optimizing Processing Section

The processing section of the SK series double screw extruder can be flexibly configured for transportation, plasticization, mixing, shearing, homogenization, devolatilization, and pressure according to the technological requirements of users' materials.

The screw and barrel of this kind of plastic extrusion equipment for sale can be made of HIP powder metallurgy material, which can achieve high wear resistance, high corrosion resistance and other extensive fields of operation.

The involute spline of the German standard (DIN5480) is adopted to meet the requirements of higher torque and higher speed.

Optimized screw size-diameter ratio (D0:D=1.55), reliable inter-model amplification effect

Internet-based New Generation Control System

The control system of SK series twin-screw extruder can choose conventional instruments, PLC, PCC, DSC to meet different needs.

Modular design, the touch screen can be compactly installed on the mainframe

Customized programming design is satisfied with the upstream and downstream matching equipment of different mixing projects

Provide formulation, project management functions, process and production data visualization

Integrating computer technology, mobile Internet technology and industrial automation technology to realize real-time data management and control of multi-terminal

Parameter of SK Series Co-rotating Twin Screw Extruder

|

SK Series Co-rotating Twin Screw Extruder Model |

Production capacity kg/hr (reference value) |

|||||||

|

Material Process Category |

Typical Material |

SK26 |

SK36 |

SK53 |

SK63 |

SK73 |

SK96 |

SK136 |

|

Filling modification |

PE, PP, EVA, etc. + calcium carbonate, talcum powder, titanium dioxide |

5~10 |

45~90 |

150~300 |

300~500 |

600~800 |

1200~1500 |

1800~2700 |

|

ABS, PC, PS, etc. + aluminum hydroxide, magnesium hydroxide, antimony oxide |

||||||||

|

PP, PA, ABS, etc. + iron powder, magnetic powder, ceramic powder |

10~20 |

90~135 |

180~300 |

380~500 |

700~900 |

1300~1800 |

1800~3000 |

|

在线联系供应商

Other supplier products

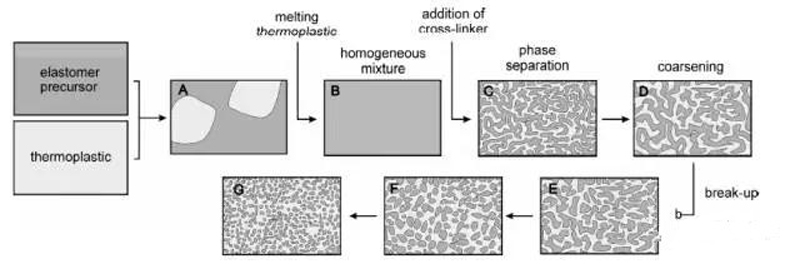

| Plastic Extruder For Thermoplastic Elastomer | Mixing Modification of Elastomer——Blending Modification of SBS/SEBS Applications of Thermoplastic Elastomer: The English acronym ... | |

| Plastic Extruder & Pelletizer For Masterbatch | Masterbatch is one important part of the plastic industry. As a professional extruder supplier and manufacturer, Nanjing KY knows a lot about maste... | |

| KY-Lab Twin Screw Extruder | Overview of KY-Lab Twin Screw Extruder Since its establishment in 1993, KY has been devoted to the development and manufacture of small lab scale t... | |

| Plastic Extruder For Thermoplastic Elastomer | Mixing Modification of Elastomer——Blending Modification of SBS/SEBS Applications of thermoplastic extrusionElastomer: The English a... | |

| AKP Series Strand Pelletizer | As the most commonly used granulation auxiliary machine, stretch granulator is one of the key equipment for users to obtain stable quality and beau... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |