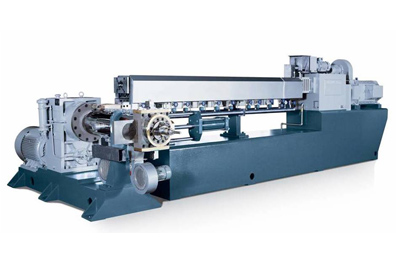

HKY / SKY Two Stage Extruder

HKY / SKY series two stage extrudersystem: the first stage is HK or SK series high speed and high torque co-rotating twin screw extruder, the second stage is single screw extruder to form a two-stage compound extrusion system.

The system combines twin screw high speed, strong mixing with single screw low speed, low temperature and weak shearing characteristics to enhance advantages and avoid disadvantages. It is the preferred model for mixing and modifying heat-sensitive and shearing-sensitive materials efficiently nowadays. The main granulation methods are air-cooled hot cutting and eccentric water mist granulation. This plastic extrusion equipment for sale can also be matched with drawing strip cold cutting and water ring hot cutting.

HK53-120 Extruder

HKY 53-120 is mainly used for the production of PVC cable materials and medical materials: the upper stage is HK 53 twin-screw extruder, the high-torque twin-screw transmission box produced by Koya

HK63-150 Extruder

HKY 63-150 is mainly used to produce EVA shielding material and PE/EVA carbon black masterbatch: the upper stage is HK 63 twin screw extruder, KY produced high-torque twin-screw transmission box

HK73-180 Extruder

HKY 73-180 low smoke halogen-free (HFFR) or halogen-free flame retardant cable material: the upper stage is HK 73 twin screw extruder

HK96-200 Extruder

HKY 96-200 is mainly used for XLPE cross-linked insulated cable material: the upper stage is HK 96 twin screw extruder

Applications of HKY / SKY Two Stage Extruder:

PVC Cable Material and XLPE Peroxide Crosslinking Material

Soft PVC Medical Material

Hard PVC Products

EVA Foamed Shoe Bottom Material

PE Low Smoke Halogen Free Resistance Fuel

Main Features of HKY / SKY Two Stage Extruder:

Plasticization, mixing and homogenization of twin screw processing section

Open melt feeding single screw extruder without backpressure, and exhaust and devolatilization can be carried out at the same time.

Soft extrusion of materials through the template of single screw extruder

Air-cooled granulation, eccentric water mist granulation, stretch granulation and water ring granulation can be selected according to material properties.

Smaller power and area

Fully automatic raw material mixing and granulation process to reduce labor costs

Easy to operate, excellent safety and stability

If you want to buy China extruder machine, please choose our company.

在线联系供应商

Other supplier products

| AKP Series Strand Pelletizer | Plastic Pelletizer Machine for Sale As the most commonly used granulation auxiliary machine, stretch granulator is one of the key equipment for ... | |

| Plastic Extruder & Pelletizer For Masterbatch | Plastic Extruder and PelletizerFor Masterbatch Masterbatch is one important part of the plastic industry. As a professional extruder supplier an... | |

| HK Large Extruder Production System | Introduction of HK Large ExtruderProduction System KY also offers a larger-scale HK twin screw extruder, with the commonly used screw diameters ra... | |

| HK Extruder for Small Batch Production | HK36 and HK53 small plastic twin-screw extruders are very competitive equipment models for small batch production scale, especially for the Color M... | |

| SK53 Twin Screw Extruder | Overview of SK53 Twin Screw Extruder SK53 small twin screw extruderis a mini extruder machine that can be used in engineering plastics, color mast... |