Automatic Assembly

Nowadays, assembly automation technologyis gradually replacing the manual assembly, since it can reduce labor costs and improve production efficiency and product stability. Yiheda has wealth of experience in developing automated assembly machine for many industries, such as automotive, low voltage electrical, hardware, precision electronics and other industries, we can provide customers with complete automation solutions with a short delivery. The assembly cycle time and precision can be adjusted according to the customer's needs, thus the performance of the equipment can be maximized.

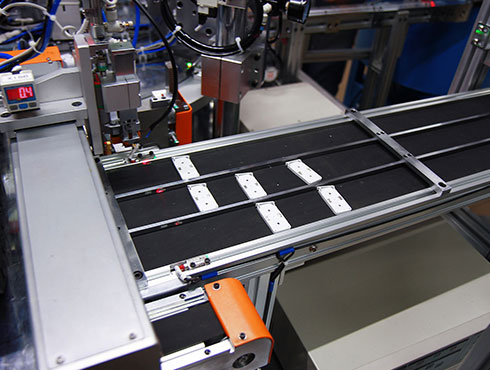

Automated assembly refers to an automatic assembly technology that replaces manual labor with automated machinery. The assembly machine design technology uses robots as assembly machinery and requires flexible peripheral equipment. During the assembly process, automated assembly can complete the following forms of operations: parts transmission, positioning and connection; press-fitting or fastening screws and nuts to fix the parts to each other; assembly size control and guarantee the quality of the connection or fixation of the parts; transporting the assembled parts or products and pack or stack them in containers, etc.

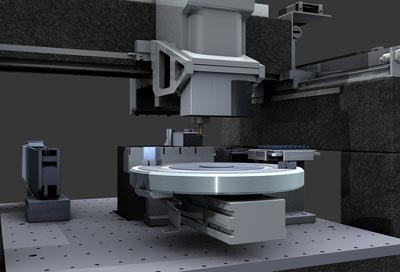

Assembly automation systems are created with the help of automation and mechanized equipment that performs various processes when creating a single item/product. Mechanical systems are usually designed to perform fixed repetitive motions, such as the fixed sequence required to assemble parts and products.

What are the assembly machine functions of the automatic assembly machine?

- assembly automation machinesrefers to the mechanism used to complete the main action of the assembly work, such as pressing, clamping, screwing, clamping, bonding, welding, riveting, bonding, welding the work piece to the previous part.

- The mechanism for picking up of automation assembly equipment machine work piece is used to sort out the assembled qualified parts and defective parts from the machine.

What is automatic assembly machine?

The automatic assembly machine refers to the mechanical equipment that combines several parts of the product through tight fitting, snapping, screwing, bonding, riveting, welding, etc. to obtain a finished product (semi-finished product) that meets the predetermined dimensional accuracy and function.

Machine features:

As one of the assembly machine manufacturers, Dongguan Yiheda Automation Co., Ltd. was established in 2010. Yiheda has 1700 staffs including 110 automation R&D personnel, specializes in designing and manufacturing the custom automation solution to customers, such as automation equipment, automatic machines, assembly solutions, industrial automation design.

在线联系供应商

Other supplier products

| Automotive rocker arm assembly machine | Yiheda automation is one of the best industrial assembly automation companies, as an expert custom automation company, specializes in designing and... | |

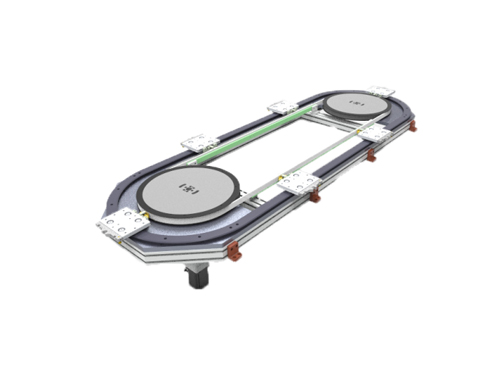

| Jig circular conveyor | The jig conveyor is driven by servo motor, the transmission structure can be customized for different loading requirements. With high accuracy and... | |

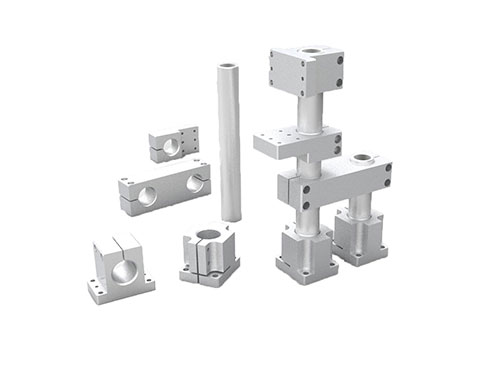

| Pillar Assembly System Mounting Plates | As one of the reliable chinese automation companies, Dongguan Yiheda Automation Co., Ltd. was established in 2010. Yiheda has 1700 staffs including... | |

| Oil Tube Welding Machine | The Oil For Welding Machinewith the linear arrangement is composed of oil tube automatic feeding station, riveting station, unloading station and g... | |

| Lithium Battery Automatic Assembly Machine | The battery assembly machinecompletes the automatic feeding, assembly and testing requirements of battery, such as battery case feeding, battery fe... |