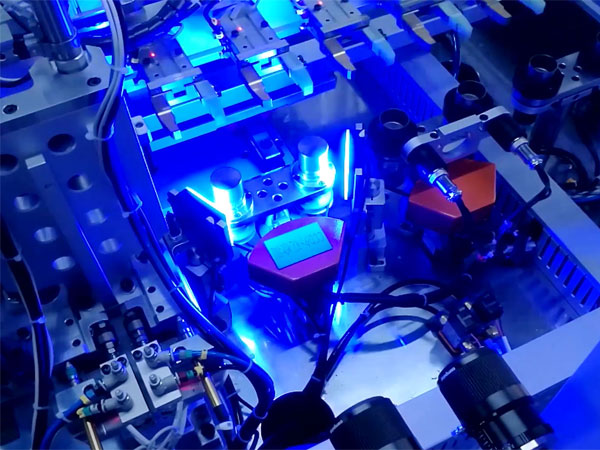

Visual Inspection

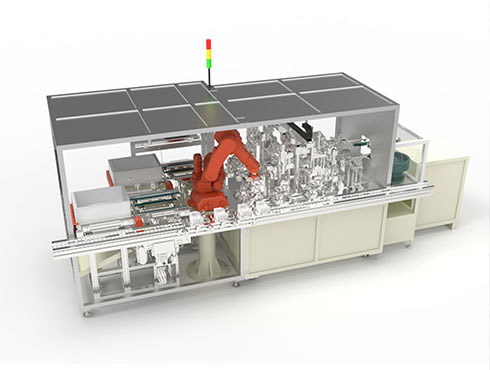

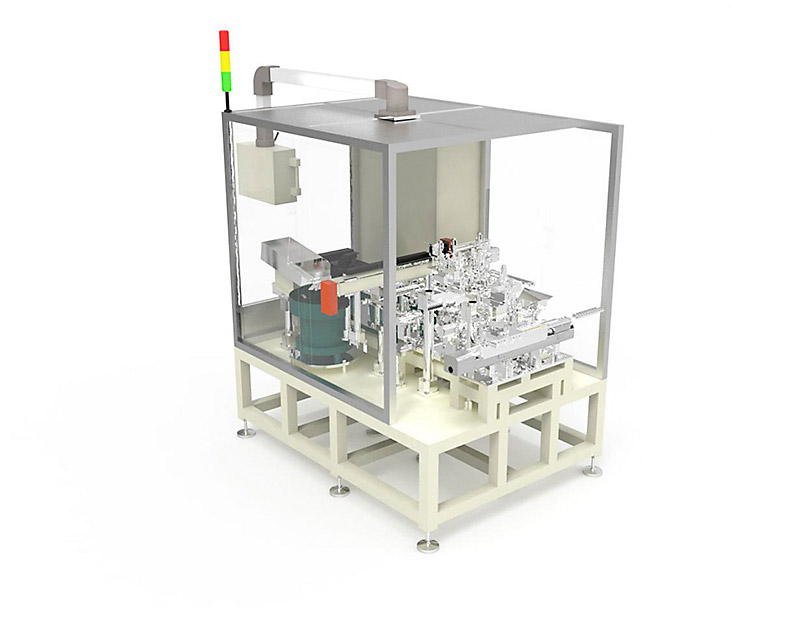

With the combination of lighting, image and data processing, the automated part inspection systems can detect and monitor the production process and product appearance damage, which guarantees the high quality of products. Automated vision inspection has been wildly use in many fields such as automotive, low voltage electrical, hardware, precision electronics and other fields. With many years of experience and abundant professional knowledge, Yiheda can design a complete automated part inspection solution based on your needs.

Industrial automated visual inspection systems are produced in industrial automation. In modern industrial automation production, it involves a wide range of inspection, measurement and part identification applications, such as auto parts size inspection and automatic assembly integrity inspection, electronic assembly line component automatic positioning, beverage bottle cap printing quality inspection, bar code and character recognition on the product packaging. The common feature of types of automated inspection systems is continuous mass production and high requirements for appearance quality. Usually this kind of work with high repetitiveness and intelligence can only be done by manual inspection. We often see hundreds or even thousands of inspection workers to perform this process behind the modern assembly line of some factories. While the factory adds huge labor costs and management costs, it still cannot guarantee 100% inspection pass rate, and today's competition between enterprises has not allowed even 0.1% defects. In some cases, such as accurate and rapid measurement of small size, shape matching, color recognition, etc., it is impossible to continuously and stably perform with the human eye, and other physical quantity sensors are also difficult to use. At this time, people began to consider to combine computer's rapidity, reliability, and reproducibility of the results with the highly intelligent and abstract capabilities of human vision, thus there is gradually forming a new

discipline - automated visual inspection equipment.

Visual inspection is the science and technology that have research on using computers to simulate the macroscopic visual functions of living things. In layman's terms, it is to use machines instead of human eyes to make measurements and judgments. Firstly, the assembly line inspection camerais used to convert the ingested target into an image signal, which is transmitted to a dedicated image processing system, and converted into a digitized signal according to pixel distribution, brightness, color and the like; the image system performs various operations on these signals to extract the characteristics of the target, such as: area, length, quantity, position, etc.: Finally, it output results according to preset tolerances and other conditions, such as: size, angle, offset, number, pass/fail, presence/absence, etc. Visual inspection is characterized by automation, objectivity, and non-contact. Visual inspection emphasizes recognition and judgment, as well as reliability in an industrial field environment compared to image processing systems in general.

Visual inspection is a fairly new and rapidly developing field of research. From the 1950s, people began to study the statistical pattern recognition of two-dimensional images. In the 1960s, Roberts began research on 3D Visual inspection. In the middle of 1970s, MIT Artificial Intelligence Lab officially opened the "Visual inspection" course, and the research began to boom globally in the 1980s, Visual inspection has flourished, new concepts, new theories continue to emerge. Today, Visual inspection is still a very active area of research, with related disciplines include: image processing, computer graphics, pattern recognition, artificial intelligence, artificial neural networks, and more.

Dongguan Yiheda Automation Co., Ltd. was established in 2010. Yiheda has 1700 staffs including 110 automation R&D personnel, specializes in designing and manufacturing the custom automation solution to customers, such as custom assembly machines, automatic machines, assembly solutions, industrial automation design.

在线联系供应商

Other supplier products

| Conveyor | The conveyor includes flat belt conveyor, synchronous belt conveyor, plastic chain conveyor, nets chain conveyor, jig straight return conveyor, spe... | |

| Low Voltage Switch Assembly Machine | Introduction of Low Voltage Switch Assembly Machine The low voltage switch assembly machine automated production machinerycompletes multiple funct... | |

| Low Voltage Switch Assembly Machine | Introduction of Low Voltage Switch Assembly Machine The low voltage switch assembly machine automated production machinerycompletes multiple functi... | |

| Feeding System | The feeding component is used for material automatic feeding includes screw feeding machine, automatic supplement machine and material hopper mac... | |

| Oil Tube Welding Machine | The oil for welding machinewith the linear arrangement is composed of oil tube automatic feeding station, riveting station, unloading station and g... |