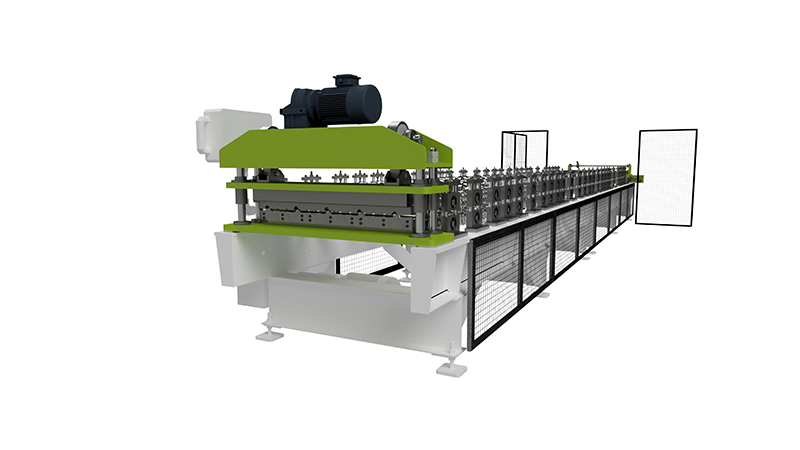

AG PANEL ROLL FORMER

This ag panel roll forming machineseries is used to make high-quality AG panels. As a professional roof and wall panel roll forming machine manufacturer, Hangzhou Roll Forming Technology Co., Ltd. provides high-quality used ag panel roll former for salefor saleat reasonable prices. Please feel free to contact us for more information.

Features and Advantages of AG Panel Roll Former

AG panel roll forming equipment, specially designed for forming roofing corrugated sheet, siding panel, floor decking, under mass-production.

Production speed: 20/30/40/50/60 m/min optional.

Working with a non-stop flying cut and full automatically stacking system, Max speed of the line can reach 60 m/min.

Cassette-type platform change rolling machine base for multi-profile purposes is available for choice.

Certified with Multi-Patents; CE Certified, EUROPEAN quality standard

Most of the hot & popular profiles models, we have a variety of ready ag panel roll forming machines in stock for prompt delivery.

Suitable Raw Material for AG Panel Roll Former

|

Material type: |

Color coated Steel, Galvanized Steel, Aluminum sheet, stainless steel |

|

Thickness: |

|

|

Yield Strength: |

230-300/350/550-675(MPa) optional |

|

Width: |

1038,1055,1092 (mm) |

Production Line Components and Parameters of AG Panel Roll Former

|

5t/8t/10t//15t Motor/hydraulic motor/passive (optional) |

|

|

optional |

|

|

optional |

|

|

no need |

|

|

20/30/40/50/60 m/min (optional) |

|

|

optional |

|

|

Motor/hydraulic (optional) |

|

|

Manual supporter/ Automatic Stacker (optional) |

|

|

Stackmaster |

(Output direction) Lateral/Longitudinal (optional) |

|

Power supply for decoiler /post-cutting system |

|

|

MITSUBISH/ SIEMENSE/AMS (optional or as requested ) |

AG Panel Roll Former Layout

Working Flow of AG Panel Roll Former

The working flow of our AG panel roll forming machines is as follows: Coil Charging Car (optional) - Decoiler (passive/auto) - Front Shear(optional) - Feeding and Guiding Table - Filming Covering (optional) - Roll Forming System - Post-Cutting to length (Hydraulic/Motor) - Output Manual Supporter/Stackmaster(optional)

Application of AG Panel Roofing

The Advantage Panel is a durable, weather-resistant metal roofing option for both residential and agricultural projects. These sturdy panels can provide excellent protection against harsh weather conditions and will increase the lifespan of your roof. Plus, AG-Panels are not only cost-effective & provide high-performance standards but they also lower the need for maintenance on your roof. Advantage panels are perfect for retro-fitting over existing composition shingles. These sheets of lower-profile metal roofing save time, labor, and disposal costs, which means a lower total project cost. The design with bold ribs, making it an exceptionally attractive and high-performance roofing and cladding.

AG Roofing Profile Drawings

Finished AG Panel Metal Roof by AG Panel Roll Former

Specification of AG Panel Roll Former

|

Machine Condition |

Fully New, A Grade quality |

|

Panel Shape |

As profile drawing and customer’s requirements |

|

Operator needed |

1-2 persons |

|

Power Supply |

220V/380V/415V/460V, 50/60Hz, 3P (as requests) |

|

Equipment Weight |

About 15t |

|

Dimension |

(L*W*H) about 25*3*2m |

|

LOADING SIZE |

Normally need 1x 40' (+ 1x 20GP) container. |

|

Equipment Color |

Normally Blue/White, or as requests; |

|

Place of Origin |

Zhejiang, China (Mainland) |

|

Packing |

Standard and careful export packing |

As a roll forming factory, we will do our best to meet all customers’needs.

在线联系供应商

Other supplier products

| Guardrail Roll Forming Machine | The highway guardrail is the main form of the semi-steel guardrail. It is a continuous structure in which corrugated steel guardrails are spliced t... | |

| Crimping & Curving Machine | Technical Parameters and Components of CrimpingCurving Machine Service and Terms of sheet crimping machine&Curving Machine As a professiona... | |

| Heavy Duty Shelf Column Roll Forming Machine | Features and Advantages of Heavy Duty Shelf Column Roll Forming Machine Cassette type platform quick-change Machine base for multi-profile purpose... | |

| Cold Roll Forming Machine | The cold roll forming machine is the equipment for continuously processing metal sheets of a coil, a strip, by a multi-pass forming roller which is... | |

| CABLE TRAY ROLL FORMING MACHINE | Well designed by engineers at Hangzhou Roll Forming Technology, this series of cable punching machines can produce rolling cable tray and caps from... |

Same products

| Micronized polypropylene wax for injection moulding | 卖方: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | 卖方: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |