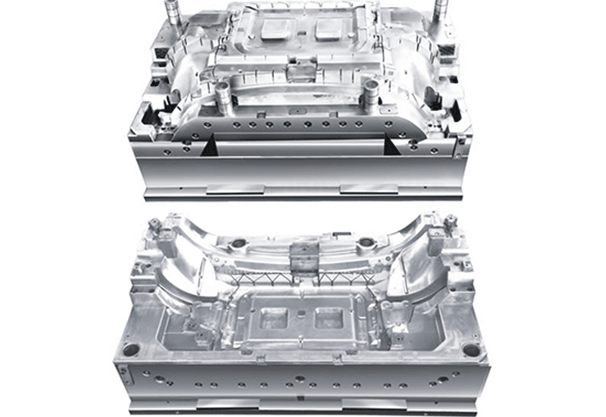

Overmolding Injection Molding

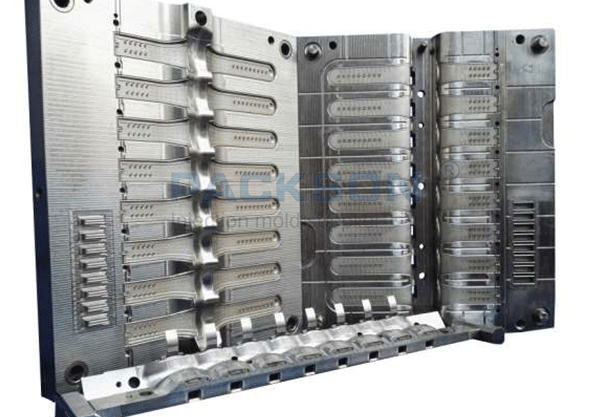

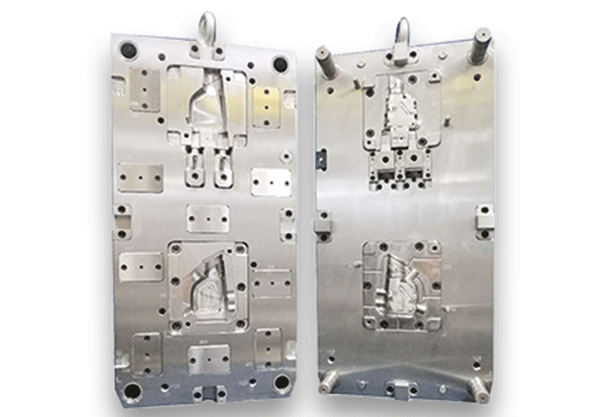

Overmolding mold is made of overmolding injection molding process which is a special injection molding process that can combine various materials into a single part. Through mechanical and/or chemical bonding of two plastic materials, the overmolding injection molding process can be used to help product designers achieve additional functions or aesthetics that are not practical.

Here at Packson, we have over 10 years experience for making contract overmoldingproduct and we've been working with BD, Lear for creating overmolded part which is used for medical and automotive overmolded parts.

Characteristics of Overmolding Mold

With the rapid development of mold making, overmolding mold becomes very popular for molding parts with better practicality. The followings are the characteristics of overmolding mold/overmolding injection molding:

Combine two materials for reaching additional function

Cheaper than molding separate two different materials

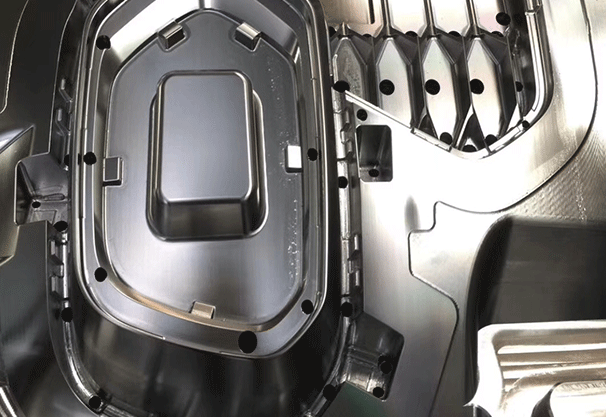

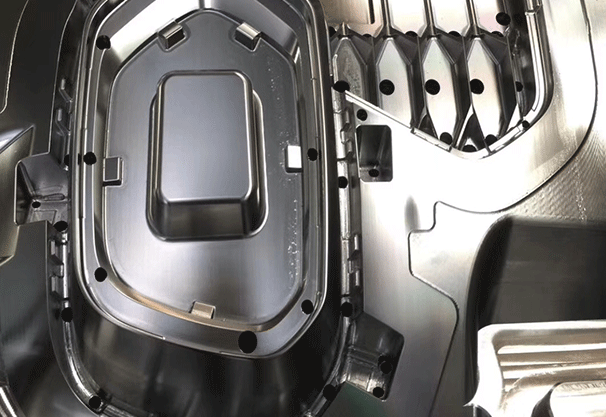

Better product properties like waterproof, shockproof, and windtight

Various textures feel

Advantages of Contract OvermouldingInjection Mold

Overmolding injection molding may cause additional cost of operating and machine costs. However it still brings us many advantages:

Improve Part Performance.

Overmolding injection molding has a strict requirement and ensures the mating of parts.

Decrease the part cost.

The overmolding remove the processing of secondary operation so it will help to reduce some labor cost also overall cost.

Enhance Design Flexibility.

It is feasible to design and manufacture complex assembly of multi-material parts by overmolding injection molding.

Overmolding Injection Molding Process

Packson's quoting system enables us to make quotations quickly by our professional quotation engineer.

Send us your part 3D to get your mold and part quote.

Confirm quotation and order issues, Packson starts the overmolding mold and part order process.

Making DFM and create overmolding injection molding process solution.

Tooling design review by Packson engineers.

Get approval of the design, Packson start building your overmolding mold.

Customer checks samples for approval.

Part mass production begins.

Application of Contract Overmolding Mold

We use overmolding injection molding for a variety of industries.Here are some examples of application for overmolding injection molding:

Consumer part

Look around you house. You can find many overmolding mold products from toothbursh to children's game parts.

Automotive Part

Electronic sensors and other automobile parts made of metal and plastic or rubber materials are usually manufactured by overmolding injection molding.

Medical Part

Defibrillators, medical cables and wires are usually made by overmolding injection molding and encapsulated in plastic for protecting important parts.

As one of the most professional medical plastic injection molding companies, Packson Moldprovides custom molding services, medical grade plastics injection moldingand etc. We have amassed considerable experience and understanding of the practical possibilities in this field. Contact us to know more.

在线联系供应商

Other supplier products

| Silicone Rubber Mold | Silicone rubber is a kind of elastic material, which is widely used in industry and family. It has become an important part of our life. Meanwhile,... | |

| Overmolding Injection Molding | Overmoldingmold is made of molding over moldingprocess which is a special injection molding process that can combine various materials into a singl... | |

| Mold Components | We provide custom made plastic parts-Sliders, inserts, lifters, blocks, ejector pins, and other mold components for our worldwide clients in 3 days... | |

| Mold Components | We provide custom made plastic parts-Sliders, inserts, lifters, blocks, ejector pins, and other mold components for our worldwide clients in 3 days... | |

| Prototype Injection Mould | Packsonmold is a company that provides high-quality prototype services, including 3D printing, CNC machining, micro-injection molding, and prototyp... |

Same products

| YC160W Wheel excavator YC160W | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |