Silicone Rubber Injection Molding

Silicone rubber injection molding has more than a half-century history since the late 1970s. There are two molding ways of silicone rubber injection molding process: Liquid Silicone Rubber Injection Molding (LSR) and Solid Silicone Rubber Molding. There are thousands of applications of silicone rubber injection molding in various industries like medical, automotive, electronics, etc.

As the one of professional silicone rubber molding company, Packson has been working with silicone molded componentsfor many years. Especially for liquid silicone rubber injection molding, we have become OEMs supplier of BD medical for producing medical rubber cathethers. We have the capability to offer liquid silicone rubber injection molding service that start from prototyping to serial production manufacturing.

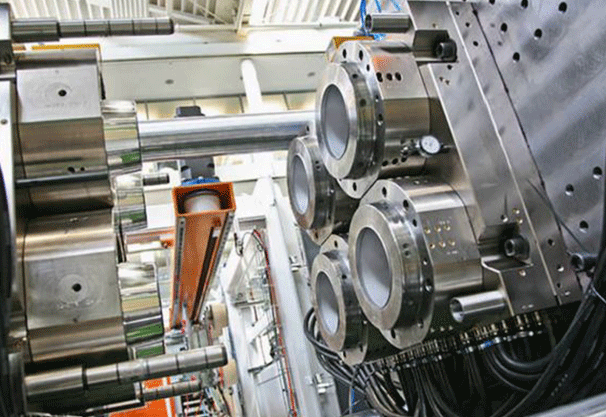

At Packson, we have equipped with more than 9 liquid silicone rubber injection molding machines with ISO class 8 cleanroom that meets the need of medical contract manufacturing. We are able to provide quick, high-quality service and our professional engineering team who has rich experience in liquid silicone rubber injection molding, to help you in the whole project process. Contact Packson today if you need liquid silicone rubber injection molding service.

Custom Silicone Rubber Injection Molding Service For Your Business

Liquid silicone rubber injection molding parts have the feature of durability with good tensile strength and are used to high volume, tight tolerance. Therefore it is widely used in various industries especially for medical parts.

Here are the advantages of liquid silicone rubber:

Excellent insulating properties, good for tight tolerance/precision components

Good tensile strength with high/low-temperature extremes

Good resistance for water, oxidation also some chemical solutions like acids.

Silicone Rubber Injection Molding ProcessThe silicone dousing unit starts in two parts

Composed A and composed B pumps one Part A silicone and one Part B silicone via separate hoses to the static mixer. Cylinder A contains the basic material. while cylinder B contains a catalyst. In addition, color is pumped to the static mixer via another hose. The mixed components are then fed into the throat of the injection molding barrel by way of a shut-off valve. This is the whole silicone rubber injectionmolding process.

Sealing against the Silicone Rubber Molded Parts

Once the silicone material is inside the barrel, a shot of the cool mixed silicone advances to the mold as the nozzle seals firmly against the silicone rubber liquid mold.

Injection

The nozzle shut-off valve opens and a measured shot of cool liquid silicone is injected into a hot (275F to 390F) clamped silicone rubber molded parts.

Barrel retracts from the mold

The nozzle shut-off valve opens and the barrel retracts from the silicone rubber liquid mold, while the screw begins to build another measured shot of cold liquid silicone.

Closes and repeats the procedure

After the cycle is complete, the mold opens and the piece and flashing can be taken off automatically or by an individual worker. After that, the mold closes and repeats the procedure.

Post-molding process

After removing the article from the mold, the post-molding process may include demisting, post-curation, inspection, and packing.

Silicone Rubber injection Molding Application

Molding Parts

-Silicone rubber injection molding can be qpplied in molding parts. Moulded part is a good way for low quantity production from dozen to hundred of the part even millions of parts. The molding part is better than the part machined by CNC or 3D printing with the same material. The right choice for resin used in the molding part allows for a wide range of properties. Mold is essential medial for the molding part. So molds machined by CNC and Wire cut EDM with high precision and tolerance are enable make thousands of parts.

Certifications

Rapid Prototye

As a professional precision mould part manufacturer, Packson Moldprovides custom molding services, medical grade plastics injection molding, clean room injection moldingand etc. We have amassed considerable experience and understanding of the practical possibilities in this field. Contact us to know more.

在线联系供应商

Other supplier products

| Clean Room Injection | Packson - Clean Room Injection Expert Packson specializes in delivering top-notch clean room manufacturing and assembly solutions tailored to meet... | |

| 2K Injection Molding | 2k plastic injection mouldingis one type of injection mold. 2k two color moldingis also named as two shot molding, double shot mold, double-color m... | |

| Explore Packson's Injection Molding Services | ISO Class 8 Clean Room Quality Control Low & High Volume Manufacturing Competitive Price Reliability and Stability With more... | |

| Plastic Injection Molding | Packson's injection molding machines range in capacity from 60-800T, providing a wide range of options for our clients. Our facility includes 40 se... | |

| Medical Plastic Injection Molding | Packson is not totally the same as other medical plastic injection molding companies. Because we are an ISO-certified medical injection molding com... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |