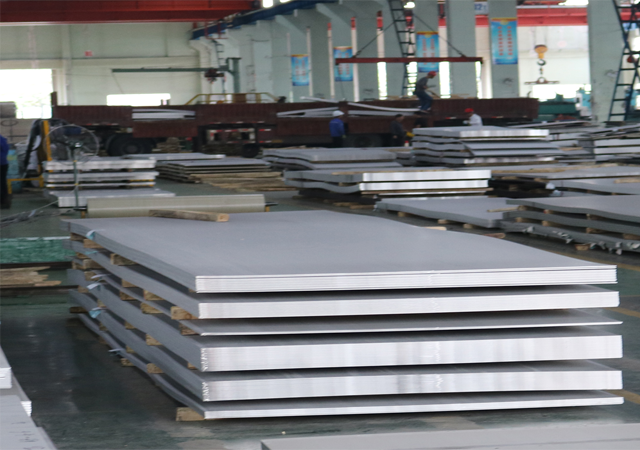

Stainless Steel Coil

Wuxi SDO stainless steel Co., Ltd is a manufacturer and supplier of stainless steel coil. Now we have advanced technology and a good reputation for our top quality. Our products, including astm a240 materialtype 304 and ohther kinds of stainless coil can satisfy our clients from all over the world. Stainless steel coil is a flexible industrial construction material made of stainless steel is generally used for mechanical production and industrial construction. Same as the stainless steel plate, the coil also has two kinds of techniques--hot rolled and cold rolled. So what's the difference between these two techniques? We will let you know in the following.

Stainless steel 304 VS astm a240 type 304

Stainless steel 304 is one of the most widely used stainless steel materials available at present. It has excellent forming and welding characteristics. Stainless steel 304 and astm a240material type 304 play a leading role in the manufacture of stainless steel products. 304 stainless steel plates can be braked to form a variety of components for industrial, construction and transportation applications. The a240 material is a low-carbon version of 304. Although 304 and a240 material plates have similar chemical properties, they all contain the same amount of manganese, silicon, phosphorus, sulfur and nitrogen.

The following are the main differences in chemical composition between the two kinds of stainless steel plates:

There are some key differences between 304 and astm a240 304. One of these key characteristics is the content of carbon and nickel. First of all, Stainless steel 304contains up to 0.08% carbon, up to 2.0% manganese and 0.75% silicon, no more than 0.045% phosphorus, no more than 0.03% sulfur, and 18.0% 20% chromium.

Stainless steel 304 consists of 8.0% to 10.5% nickel and up to 0.10% nitrogen. The carbon content of stainless steel 304 does not exceed 0.08%, while the maximum carbon content of astm a240 material 304 is 0.03%. ASTM a240 material 304 has a nickel content of up to 12.0%, while stainless steel 304 has a nickel content of up to 10.5%.

What Are The Characteristics Of Stainless Steel Coils?

The hot steel strip from the last rolling mill of finishing rolling is cooled to the set temperature by laminar flow and then coiled onto the steel coil by the coiler. Then after HAPL, the black coil will become white, like what we saw in daily life. The whole processing is showing as below:

SCRAP -- EAF -- AOD -- CCM -- SLAB -- REHEATING FURNACE -- ROUGHING MILL -- STECKEL MILL -- LAMINAR FLOW -- DOWN COILER -- BLACK COIL -- FURNACE -- SCALE BREAKER --SHOT BLASTER -- PICKLE -- SPM -- WHITE COIL.

Usually, the thickness of hot rolled stainless steel is 3.0mm -- 150mm, width and length can be decided by the customer self.

Cold rolled stainless steel coil is processed and rolled on the basis of hot rolled.

SCRAP -- EAF -- AOD -- CCM -- SLAB -- REHEATING FURNACE -- ROUGHING MILL -- STECKEL MILL -- LAMINAR FLOW -- DOWN COILER -- BLACK COIL -- FURNACE -- SCALE BREAKER --SHOT BLASTER -- PICKLE -- SPM -- WHITE COIL -- ZRM -- CAPL -- SPM -- SCL.STL. TLL.

Usually, the thickness of cold-rolled stainless steel coil is 0.2mm -- 3.0mm, width and length can be decided by the customer self.

Technologies Of Stainless Steel Coil

As we all know now, stainless steel has different process techniques, we will talk about this in this part. We can classify stainless steel coil from different aspects.

By Technique--hot rolled and cold rolled

The hot-rolled process of stainless steel is based on slab ( mainly continuous casting slab) as raw materials, which are heated to produce strip steel from the rough rolling mill and the finishing mill.

The cold-rolled stainless is a hot-rolled coil after cold annealing and pickling. The cooled steel coil has an oxide scale on the surface and appears black, commonly known as "stainless steel black coil".

As reliable stainless steel factory, we have types of stainless steel pipefor sale, if you have needs, please contact us.

在线联系供应商

Other supplier products

| Stainless Steel Coil | Wuxi SDO stainless steel Co., Ltd is one ofstainless steel suppliers. Now we have advanced technology and a good reputation for our top quality. Ou... | |

| 310S Stainless Steel Strip | AISI310sis austenitic chromium-nickel stainless steel with good oxidation resistance and corrosion resistance. Because of the higher percentage of ... | |

| 304L Stainless Steel Sheet | 304L Stainless Steel Sheet 304L is a steel grade obtained by reducing the carbon content of 304 to less than 0.03%. Its general characteristics ar... | |

| Stainless Steel FLAT BAR | Stainless steel flats steel is rectangular steel with slightly pure edges. Stainless steel flat steel can be semi-finished steel. In practical appl... | |

| 316L Stainless Steel Sheet Corrosion Resistance | Chinese Standard (GB)-old grade: 00Cr17Ni14Mo2, new grade: 022Cr17Ni12Mo2, Japanese standard: SUS316L, American standard ASTM-316L, as a low-c seri... |

Same products

| YC160W Wheel excavator YC160W | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |