Automatic Blow Molding Machine

- blow molding machinehas great advantages in the clean production and energy saving of blow molded products, and automatic blow molding machine's research and development progress are relatively fast.

For some blow molding production workshops that require a high degree of cleanliness, electric blow molding units will be one of the first choices.

- auto deflashing blow moulding machineare excellent equipment for modern industrial production.

- fully automatic blow moulding machineequipment manufacturing price and costs, it may be promoted to other blow molding product industries.

Description about Automatic Blow Molding Machine

|

Item |

Description |

|

Place of origin |

China |

|

Brand name |

JWELL |

|

Model number |

Electric Blow Molding Machine |

|

Minimum order quantity |

520/650/850 |

|

Packaging details |

Wooden pallet packing |

|

Delivery time |

90days |

|

Payment terms |

Specifications of Automatic Blow Molding Machine

|

TechnicalDetails |

|||

|

Model |

JWZ-EBM-520 |

JWZ-EBM-650 |

JWZ-EBM-850 |

|

Mainscrewdiameter |

75/80 |

80/90 |

90/100 |

|

L/D |

25:1 |

25:1 |

25:1 |

|

Screw speed |

25~75r/min |

25~75r/min |

25~75r/min |

|

Mainscrewdiameter |

75/80mm |

80/90mm |

90/100mm |

|

Maxplasticizingcapacity |

95-115 kg/h |

115-140 kg/h |

140-180 kg/h |

|

Mould Moving |

520mm |

650 |

850 |

|

Mould-opening stroke |

2x100mm |

2x120mm |

2x120mm |

|

Clampingforce |

120kN |

240kN |

300kN |

|

400x380mm |

550x400mm |

750x400mm |

|

Automatic Blow Molding Machine Application

Automatic Blow Molding Machine Application

JWELL machinery chinais researching and developing a fully electric Blow molding machine to meet the Food, Medical, Health, and other industries' requirment for the machine and product clean. Compare with the traditional Hydraulic type blow molding machine, The fully electric blow molding machine adopts fully servo-driving motor, energy-saving about 30%.No oil-leakage. Fully automatic blow moulding machine has low noise and can keep the workshop.

Automatic Blow Molding Machine Performance and Advantages

Energy consumption

The use of servo motors and servo drives can effectively save energy, and the energy-saving efficiency is generally 50% to 70% (depending on the product).

Cleanliness and noise

All servo motors are used, and there is no noise caused by hydraulic pumps. The decibels are reduced by 10-15dB. There is no oil leakage problem. The workshop is very clean and easy to maintain.

Response

Faster response time, greater efficiency, and control range. Higher and wider, especially suitable for high-speed and large-volume extrusion blow molding machine.

Accuracy and repeatable positioning

fully closed-loop control, high-precision encoder, controllable within 0.02mm, suitable for the production of high-precision products, high repeat positioning accuracy.

在线联系供应商

Other supplier products

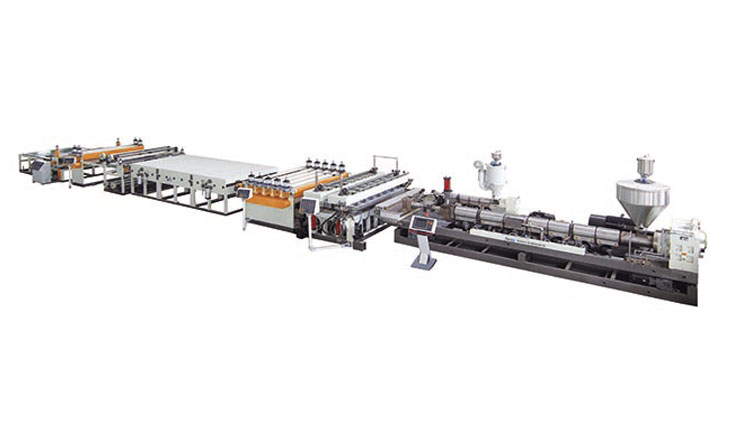

| PC Sheet Extrusion Line | Jwell's PC Sheet Extrusion Line, PMMA Sheet Extrusion Lineis mainly divided into the following types: Application scope of PC endurance board: gar... | |

| Extrusion Line | Here, you can learn about various JWELL extrusion line and related components of extrusion line machine, such as sheet extrusionline, plate extrus... | |

| HDPE Pipe Extrusion Machine | HDPE pipe extrusion lineadopts the most advanced technology of Europe, It is a new research achievement of energy-saving production line, which is ... | |

| Film Extrusion Line | Film extrusion lineis a kind of screw plastic film extruder. The working mechanism of screw plastic extruder is to fully plasticize the materials b... | |

| PP Hollow Sheet Extrusion Line | Jwell hollow plates are as follows: PP Hollow Building Formwork Double Out Extrusion Line: PP hollow building template the first mock exam double... |