Horizontal Machining Center

single station

Suitable for various heavy cutting and high precision machining fields

TYPES OF HORIZONTAL MACHINING CENTER FOR SALE

HORIZONTAL MACHINING CENTER ADVANTAGES

The new horizontal machining center is generally used for processing box parts. The overall structure of the horizontal machining center is suitable for the processing of box parts. The horizontal machining center is composed of three linear coordinates and a workbench rotating shaft, which can clamp box parts at one time and complete the processing of multiple surfaces.

Through one clamping, the accuracy error caused by clamping is reduced, It has high machining precision and stable machining quality, which not only shortens the production cycle but also reduces the production cost of the enterprise. The horizontal machining center has obvious advantages in chip removal ability for machining box parts. Compared with large vertical machining centers and gantry machining centers, its machining advantages and machining effect have been recognized by the majority of users.

HORIZONTAL MACHINING CENTER FAQS

What parts are suitable for horizontal machining center?

A horizontal machining center is suitable for the mass production of products with complex shapes and high precision requirements, especially the machining of the box and complex structural parts. It is widely used for precision and efficient machining of complex parts in automotive, aerospace, shipbuilding, and power generation industries.

What is the characteristics and processing requirements of box parts?

The machining process of box parts generally has multi-station machining requirements for hole system, contour, and plane. It usually goes through milling, boring, drilling, expanding, reaming, tapping, and other processes. There are many tools and tooling used. It needs to be clamped and aligned many times on conventional machine tools, and the measurement times are many. Therefore, the machining cycle is long, the cost is high, and the accuracy is difficult to be guaranteed.

What are the common box parts?

Common box parts generally include automobile engine cylinders, automobile gearbox, transmission gearbox, etc.

As one of the professional cnc hmc machinecnc machining center suppliers,deed machinehas won the user's universal praise.

在线联系供应商

Other supplier products

| CNC MACHINING CENTER | CNC milling machine is automatic processing equipment developed on the basis of a general milling machine. Their processing technology is basically... | |

| VL-SERIES VERTICAL MACHINING CENTER | VL series vertical machining center is a small and medium-sized vertical machining centerdesigned by Germany and made in China. It mainly aims at t... | |

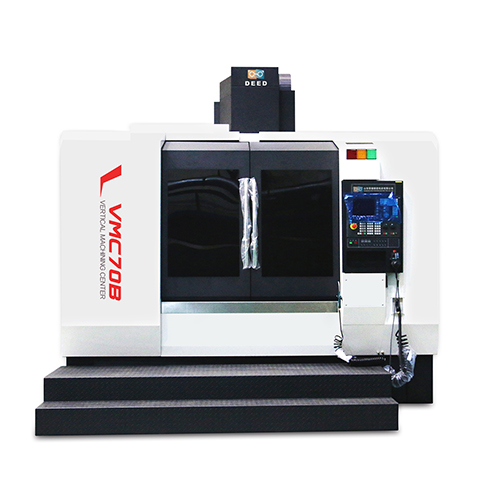

| VMC-SERIES VERTICAL MACHINING CENTER | As a vmc machine company, DEED VMC-series Vertical Machining Centeris mainly suitable for processing complex parts such as plates, discs, molds, an... | |

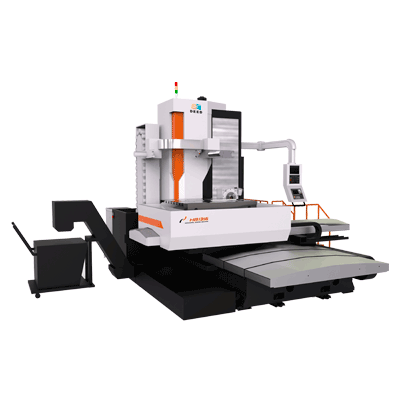

| CNC Milling and Boring Machine | The maximal rotation of spindle can reach 2500rpm/min It can meet the large-torque requirement during the rough machiningand the high rotational... | |

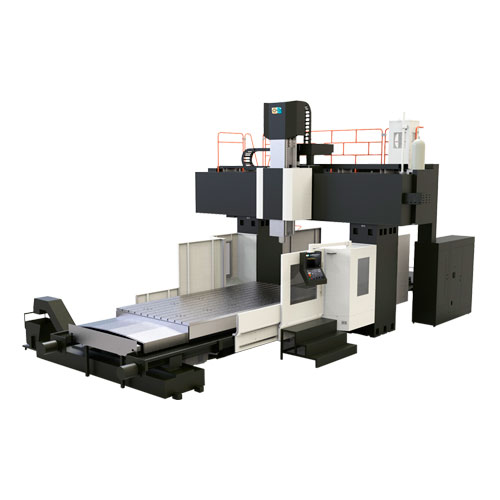

| GL-SERIES GANTRY MACHINING CENTER | Gantry Milling machine GL series has an Excellent high-rigidity structure and Cost-effective full-stroke machining tool. According to different Y-a... |

Same products

| Micronized polypropylene wax for injection moulding | 卖方: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | 卖方: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |