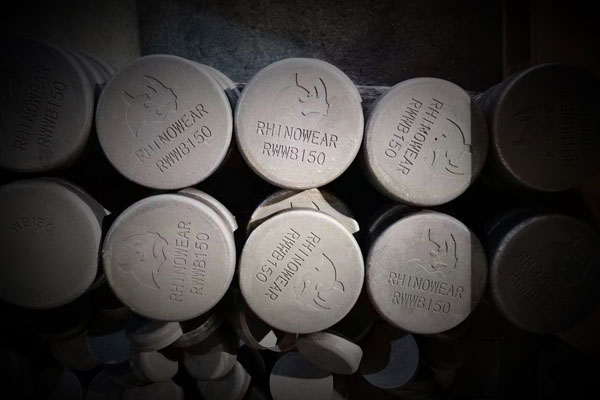

Chocky Wear Bars, Wear Buttons

The unique, formable design of Chocky wear bars and wear button are available in various lengths, grades and sizes and can also be customized as per the client's specific need. Applications for Chocky Bars are wide and varied, ranging from specific wear protection on buckets for loaders, excavators, and draglines machines, or for weld-on hammer tips for the re-cycling industry, or chute linings and rock box edges.

These casting components are easy to use and install. They can be bent, cut, and formed to suit different surfaces. The standard is 23mm thick, length is 240mm, width could be from 25mm from 150mm. We can also produce according to your special requests.

Why Choose WALKSONChocky Wear Bars, Wear Buttons

Super high level wear resistant ability

Custom made size to suit your need

Very stable brazing welding quality

Want to know the details of Chocky Block and

Chocky Bars, contact us.

在线联系供应商

Other supplier products

| Chocky Wear Bars, Wear Buttons | Chocky Wear Bars, Wear Buttons The unique, formable design of Chocky wear bars and wear button are available in various lengths, grades and sizes ... | |

| Undercarriage System | Undercarriage System Walksonis a qualified supplier of crawler system for large hydraulic excavators and electric rope shovels. We have system o... | |

| Butterfly Valve | Walkson, as a reputable a butterfly valve company, provides butterfly valve castingand forgings for different types of butterfly valves. The actuat... | |

| Adaptor | Adapter is one of the most important part of G.E.T system, especially the cast lip system. Either made by casting or forging, an adaptor installed ... | |

| Check Valve | As a professional high pressure check valve part manufacturer, Walkson provides castings or forgings for adjustable cracking back check valves. ... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |