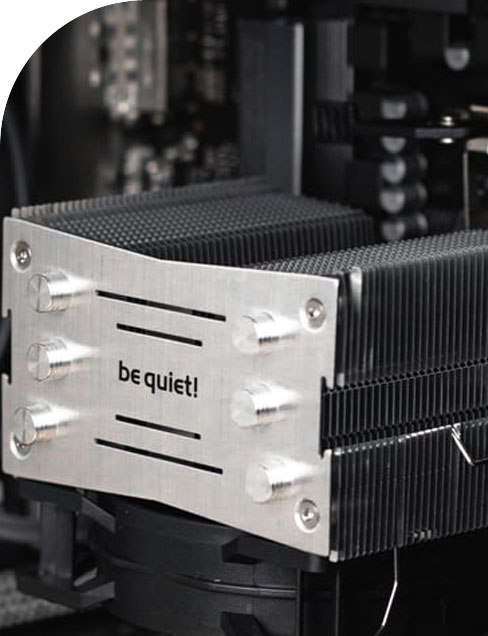

Electroplating Service Of Metal Stamping

Electroplating is the process of using electrolysis to attach a layer of the metal film to the surface of metal or other materials so as to prevent metal oxidation, improve wear resistance, electrical conductivity, reflection, corrosion resistance, and enhance the role of beauty. Orienson has complete supporting resources, which can provide customers with different plating methods such as continuous plating, barrel plating, rack plating, and different plating types such as gold plating, silver plating, tin plating, nickel plating, zinc plating, zinc-nickel alloy plating, etc., and can be tested and controlled by XRay coating thickness tester, Brine spray tester, high temperature, and high humidity testing machine and other equipment.

What Is The Process Of Metal Electroplating?

Basic Process

(grinding → polishing) →racking→degrease & oil removal→washing → (electrolytic polishing or chemical polishing) → activation → (preplating) → plating → washing → (post-process) → washing→dry→ taking down →Inspecting packing

02

The Role Of Pretreatment Process

Pretreatment: all processes before plating are called pretreatment, the purpose is to dress the surface of the workpiece, remove the grease, rust, oxide film on the surface of the workpiece, and provide the required electroplating surface for the subsequent deposition of the coating.

03

The Role Of Electroplating Process

Electroplating is getting the required coating on the surface of the workpiece, also is the core process of the electroplating process. The quality of this process directly affects the properties of the coating.

04

The Role Of Post-treatment Process

Post-treatment: after electroplating, the coating is processed to enhance the various properties of the coating, such as corrosion resistance, anti-discoloration ability, solderability, etc.

Benefits Of Metal Electroplating

Different effects can be obtained according to various electrodeposits:

What is Metal Electroplating?

Electroplating is the method of electrolysis to make metal or alloy deposition on the workpiece surface, in order to form a uniform, dense, good bonding force of the metal layer process. Electroplating coating is uniform, generally thin, ranging from a few microns to dozens of microns. Through electroplating, we can obtain decorative protective and various functional surface layers on mechanical products, but also repair wear and processing errors of the workpiece.

As a professoinal metal stamping manufacturerandmetal plating company, we provide metal plating services, metal plating plastic, custom metal stampings,

metalwork and stampingand etc.Want to know metal plating types or more, contact us.

在线联系供应商

Other supplier products

| Automotive Metal Stamping | Orienson has expanded into the automotive components market for years and produces the highest quality components for the world's top automotive br... | |

| Deep Drawing Parts | Deep drawing molding is a stamping processing method that uses the die to shape the flat blank into an open hollow part. Orienson's Deep Drawing P... | |

| Copper Stamping | Copper stampingis the processing of copper metal materials into custom-shaped hardware through stamping die. Orienson's Copper Stamping Copper is ... | |

| Fine Blanking Parts | Fine blanking is short for precision blanking. Orienson's Fine Blanking Parts Fine blanking is a kind of precision stamping processing technology... | |

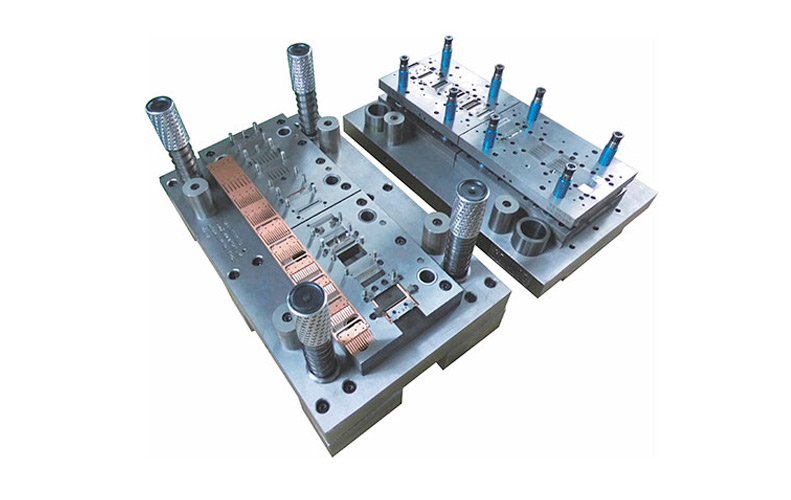

| Progressive Die | Progressive die(also known as continuous die) is referred to the punch in a stroke, in a few different positions, at the same time to complete the ... |