Lanpack

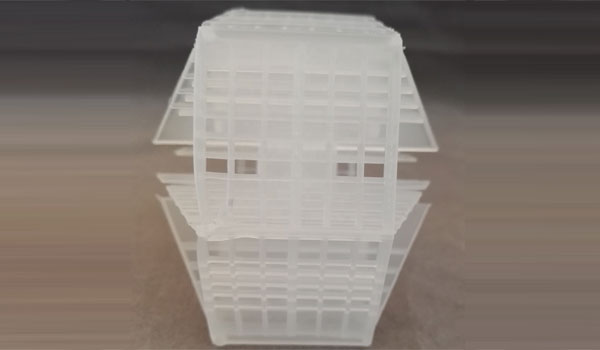

Plastic Lanpack PackagingFor Tower Packing is the most distinguishing feature. This design enables an extraordinarily high scrubbing efficiency while minimizing the amount of media and packing depth required. Meanwhile, Evenly spaced rod design can largely eliminate clogging. Each layer's vertical downward rod's distribution is not

only broken large droplet, but also form many gas-liquid contacting areas. It will improve separation efficiency. Plastic LanpackPacking is widely used in wet scrubber & gas stripping.

Parameters of Lanpack

|

Size |

Surface Area |

Void Rate |

Packing Number |

Packing Density |

Dry Packing Factor |

|

mm |

m2/m3 |

% |

piece/m3 |

k/m3 |

m-1 |

|

60 |

222 |

89 |

7060 |

84 |

69 |

|

90 |

144 |

1760 |

56 |

46 |

Characteristics of Lanpack

High capacity of gas and liquid flow rates

Extremely low pressure drop

High liquid loading

High seperation efficiency

High mass transfer efficiency

Application of Lanpac Packing

Before understanding the Application of Lanpac Packing, first of all, a brief introduction to the structural advantages of Lanpac Packing, which will make it easier for us to understand its application.

Lanpac Packing's innovative geometry design has a more reasonable packing flow structure, small resistance drop, strong processing capacity, high mass transfer effect, large load elasticity, more the packing design structure strength, longer service life, and the same material to maintain the packing does not deform the application temperature is higher, sleek shape structure and high void ratio, has excellent anti-scaling and anti-clogging characteristics, significantly improve the equivalent gas/liquid contact area. Lanpac Packing has a unique design that provides surface access to exhaust and scrubbing liquids. The product has a very high purge efficiency and has proven to be an excellent tower packing for applications with high liquid loads.

The main applications of Lanpac Packing are in the following areas:

NaikeChemical has been established from the consortion of several existing factories since 1973. Nowadays, Naike chemical is developing to the top leading manufacturer of molecular sieve products and mass transfer products(column packing and column Internal parts). Base on the distinguished and experienced techinical team to provide the up-to date molecular sieve and mass transfer products & technologies, Naike aims at Worldwide technical cooperation and products supply.

在线联系供应商

Other supplier products

| TOWER PACKING/COLUMN PACKING | Leading Tower Packing/Column Packing Tower packing refers to the tower packing in the packed tower. The function of tower packing is to provide suf... | |

| MCM-22 Zeolite | Mesoporous Molecular sieve mcm 22 zeoliteis a novel microporous molecular sieve with MWW structure. In the molecular sieve layered structure of the... | |

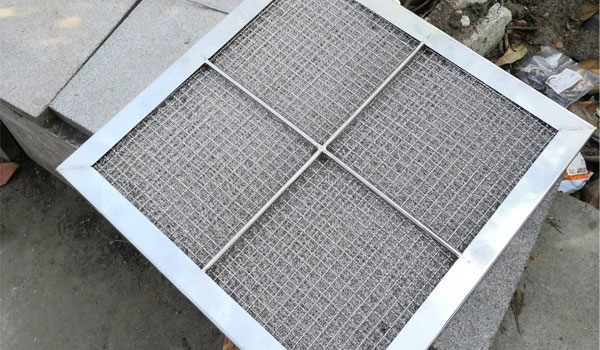

| Pad Demister With Frame/Mist Eliminator With Frame | NAIKEKnitted Wire Mesh is a kind of wire mesh knitted in particular type. It is used for wire mesh demister, oil-gas separator, dust remover, dedus... | |

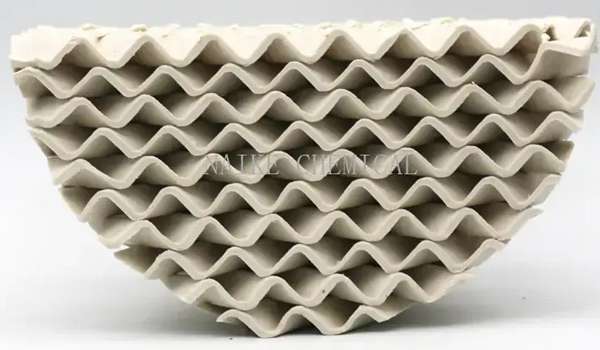

| CERAMIC STRUCTURED PACKING | Ceramic structured packingis made up of many packing unit bodies that share the same geometry shape. Corrugated ceramic packing is called Kelapak p... | |

| 5A Molecular Sieve | 5A Molecular Sieve is an alkali alumino silicate; 5A Molecular sieve is the calcium form of the Type A crystal structure. 5A Molecular Sieve has an... |

Same products

| YC160W Wheel excavator YC160W | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |