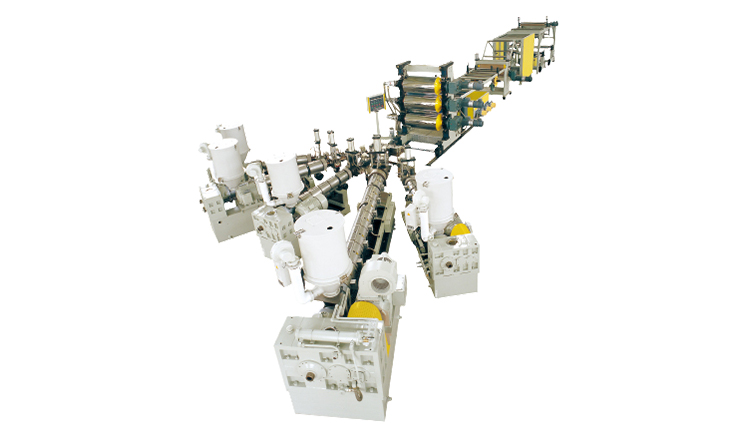

POY Spinning Machine

POYspinningadopted Newly designed Spin-Beam with less energy consumption by 30% compared with conventional ones.

Adopted Bottom mounted spin packs with better melt flow, better temperature evenness and less manpower required.

New type of poy machine quenching system providing smoother air blowing for the better yarn evenness.

The adjustable Air-Blowing area and Air Volume enabling further spinning process adjustment.

Fully Automatic Winders with precision winding, featuring higher successful changer-over rate and excellent bottom layer yarn unwinding and tail yarn shifting.

Polyester spinning machinesuch as polyester, PA6, Nylon POY spinning has guide Roller with Individual Control System (Movable Godet system in optional)

Descripetion about POY Spinning Machine

|

Material |

PET |

PA6 |

|

Denier(D) Range |

50-600 |

40-70Process speed |

|

Process speed |

3200m/min |

4300m/min |

|

6 / 8 /10 / 12 positions(customized) |

||

|

8 /10 / 12 ends(customized) |

||

|

Winders |

Automatic |

|

|

Grade class rate |

up to grade class rate ≥98﹪,first class rate ≥95﹪,full package rate≥90﹪ |

|

Specifications of POY Spinning Machine

|

Item |

Specification |

|

Place of origin |

China |

|

Brand name |

JWELL |

|

Model number |

PET PA6 |

|

Certification |

CE ISO |

|

Minimum order quantity |

1 SET |

|

Packaging details |

Wooden pallet packing |

|

Delivery time |

90days |

|

Payment terms |

POY Spinning Machine Application

Filament is a continuous thread obtained by processing natural or chemical fibers, and has not undergone a cutting process.

JWELL machine uses POY as raw yarn, which is stretched and false-twisted to make DRAW TEXTURED YARN (DTY). Often have a certain degree of elasticity and contractility.

POY chemical fiber is widely used in the manufacture of clothing and industrial products. Due to its flame retardancy, flame-retardant polyester has a wide range of applications. In addition to its irreplaceable role in industrial textiles, architectural interiors, and interior decoration of vehicles, it also plays a lot of roles in the field of protective clothing. In addition to pure flame-retardant polyester, it can produce flame-retardant, waterproof, oil-repellent, anti-static and other multi-functional series products according to the special requirements of users.

POY Spinning Machine Performance and Advantages

Partially Oriented Yarn Manufacturing Process

HomeProductsYarn Spinning MachinePOY Spinning Machine

POY Spinning Machine

POY spinning machine adopted Newly designed Spin-Beam with less energy consumption by 30% compared with conventional ones.

Adopted Bottom mounted spin packs with better melt flow, better temperature evenness and less manpower required.

New type of poy machine quenching system providing smoother air blowing for the better yarn evenness.

The adjustable Air-Blowing area and Air Volume enabling further spinning process adjustment.

Fully Automatic Winders with precision winding, featuring higher successful changer-over rate and excellent bottom layer yarn unwinding and tail yarn shifting.

POY spinning machine such as polyester, PA6, Nylon POY spinning has guide Roller with Individual Control System (Movable Godet system in optional)

poy spinning machine

partially oriented yarn manufacturing process

Descripetion about POY Spinning Machine

MaterialPET PA6

Denier(D) RangeProcess speed

Process speed3200m/min4300m/min

- 6 / 8 /10 / 12 positions(customized)

- 8 /10 / 12 ends(customized)

WindersAutomatic

Grade class rateup to grade class rate ≥98﹪,first class rate ≥95﹪,full package rate≥90﹪

Specifications of POY Spinning Machine

ItemSpecification

Place of originChina

Brand nameJWELL

Model numberPET PA6

CertificationCE ISO

Minimum order quantity1 SET

Packaging detailsWooden pallet packing

Delivery time90days

Payment terms

POY Spinning Machine Application

Filament is a continuous thread obtained by processing natural or chemical fibers, and has not undergone a cutting process.

Jwell extrusion machineryuses POY as raw yarn, which is stretched and false-twisted to make DRAW TEXTURED YARN (DTY). Often have a certain degree of elasticity and contractility.

POY chemical fiber is widely used in the manufacture of clothing and industrial products. Due to its flame retardancy, flame-retardant polyester has a wide range of applications. In addition to its irreplaceable role in industrial textiles, architectural interiors, and interior decoration of vehicles, it also plays a lot of roles in the field of protective clothing. In addition to pure flame-retardant polyester, it can produce flame-retardant, waterproof, oil-repellent, anti-static and other multi-functional series products according to the special requirements of users.

POY Spinning Machine Performance and Advantages

Partially Oriented Yarn (POY) Manufacturing Process

Partially oriented yarns are made by melting extrusion (melting spinning) of polyester slicing or slicing. During poy spinning, the filaments are stretched or stretched up to five times their original size to Orient the polymer to achieve the desired uniformity, strength, shrinkage and elongation properties. Thus, the term POY refers to a multi-fiber that is only partially stretched. POY is generally less strong and less uniform than full oriented yarns (FOY). POY is mainly used for fabricating textured yarns, but also for weaving fabrics and warping.

POY Spinning Machine Packing & Shipping

在线联系供应商

Other supplier products

| Multilayer Extruder Machine | Due to the increasingly stringent requirements of the market for products, Jwell has developed advanced five-layer symmetric and seven-layer asymme... | |

| Plate Extrusion | Plate Extrusion Plate extruder is one of the screw plastic extruders. The working mechanism of screw plastic film extruderis to rely on the pressu... | |

| Sheet Extrusion Line | Sheet extrusion linerefers to the production equipment which is used to heat the plastic raw materials (particles) in the plastic extruder, melt th... | |

| PP Blow Moulding Machine | PP blow moulding machine is a product formed by a rapidly developing plastic processing method. Use PP plastic to extrude one-time blow molding. Du... | |

| Spandex Machine | Spandex is the earliest developed and most widely used variety among elastic fibers and the most mature production technology. Normally two ways... |