Battery Cold Plate

The main materials of battery cooling plates are aluminium alloy and stainless steel. Due to the requirements of low density and various forming processes, aluminium alloy can meet the lightweight requirements of the application end. At present, there are two process schemes for battery cold plate: integral casting and aluminium profile welding. And the technique of FSW is favored by more and more new energy automobile OEMs at home and abroad.

FSW welding has been widely used in the manufacture of EV battery cooling platesand EV battery tray FSW because of its non-melting, automation, intelligence, environment-friendly and integrated characteristics.

Cheevenis a professional die casting parts factory, we provide cold plate electric, metal cooling plate, carbon nanotubes products, etc. For battery tray priceand more information, please feel free to contact us!

There are many cold plate suppliers, but we are one of the best choices for you.

在线联系供应商

Other supplier products

| FRICTION STIR WELDING APPLICATION | FRICTION STIR WELDING APPLICATION Car Manufacture Under the premise of advocating global environmental protection today, the new energy vehicle... | |

| Electric Heating Radiator | It can be used in industrial plants, smart homes, and other scenarios. LED digital screen control, can be timed, can be connected to WIFI, and can ... | |

| High-strength and High-elasticity Copper-nickel-manganese Alloy | High-strength and high-elasticity copper manganese nickel alloyis mainly used for the manufacture of various current-carrying elastic elements, ela... | |

| Battery Tray Holder | Aluminum battery traylower box of battery pack is mainly made of steel and aluminium alloy. Aluminium alloy is favored by more and more automobile ... | |

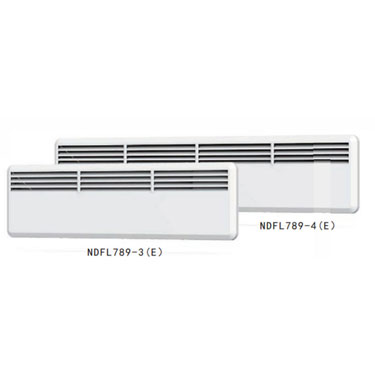

| Convection Heater | Cheeven provides convection heaterwhich have steel panels, power 1000/1500/2000W, power switch, LED digital screen control, settable temperature ra... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |