TBK-288 Screen Heating Separator intelligent control Teardown machine

TBK 288 automatic cell LCD screen disassembly platform to dismantle iPhone. 2022 newest TBK 288 screen heating separator Apple Self Service repair tool for heating iPhone LCD screen and opening it automatically. Apple iPhone disassembly machine TBK-288 screen remover fixture for tearing down mobile s automatically.TBK 205 automatic centering fixture removable LCD suction cup for mobile screen repair.

TBK 288 fully automatic intelligent control screen removal iPhone disassembly platform, with a universal mold, one key start, accurate constant temperature heating, intelligent programmed control jacking, automatic and manual jacking switching, intelligent LCD screen control.

Features:

1. Fully automatic screen removal,just put your on and start it with one-key, automatic heating and screen removal.

2. Universal mold for Apple iPhone series, automatic regulating heating block.

4. There is no need to adapt the corresponding models separately. One automatic platform is suitable for all iPhone models(iPhone 5S-13 Pro Max), and the subsequent release of new models can be expanded infinitely.

3. Frame constant temperature precise heating, thermostatically heated frame only, without damaging the inside of the , the battery, etc.

4. Built in vacuum pump, strong vacuum pump sucks the mobile , the lower suction cup absorbs the iPhone, making it more fixed and stable; the upper suction cup absorbs the iPhone to separate the LCD assembly of the iPhone from the middle frame.

5. Automatic vacuum breaking.

6. Intelligent program jacking, the jacking height can be controlled freely, preventing the line from being damaged by lifting.

7. Automatic top mobile . After separation, the iPhone with automatic jacking is easy to take out, not heat, safety guarantee.

8. intelligent LCD control.

9. Automatic and manual switchable.

10. Wide voltage(110-240V).

Instructions:

1. Plug in the power cable and turn on the power button.

2. Put the Mobile Phone into the universal mold.

3. Click the setting butong on the LCD screen to enter the parameter setting.

4. Set the heating XY temperature and heating time(both sides and middle).

5. Set the jacking times of the intelligent program.

6. Press the start button to start an intelligent screen removal platform.

Structure:

1. Intelligent program control jacking.

2. Vacuum tube.

3. Automatic fixture constant temperature heating.

4. Jack up mobile .

5. Intelligent LCD screen.

6. Vacuum sucker.

7. Cooling holes.

8. Manual top separation.

9. Start button.

10. Emergency Stop button.

Parameter:

Model: TBK-288.

Voltage: 110-240V.

Power: 400W.

Product size: 42*30*21cm.

Package size: 48*38*30cm(wooden box).

Gross weight: 15KG.

在线联系供应商

Other supplier products

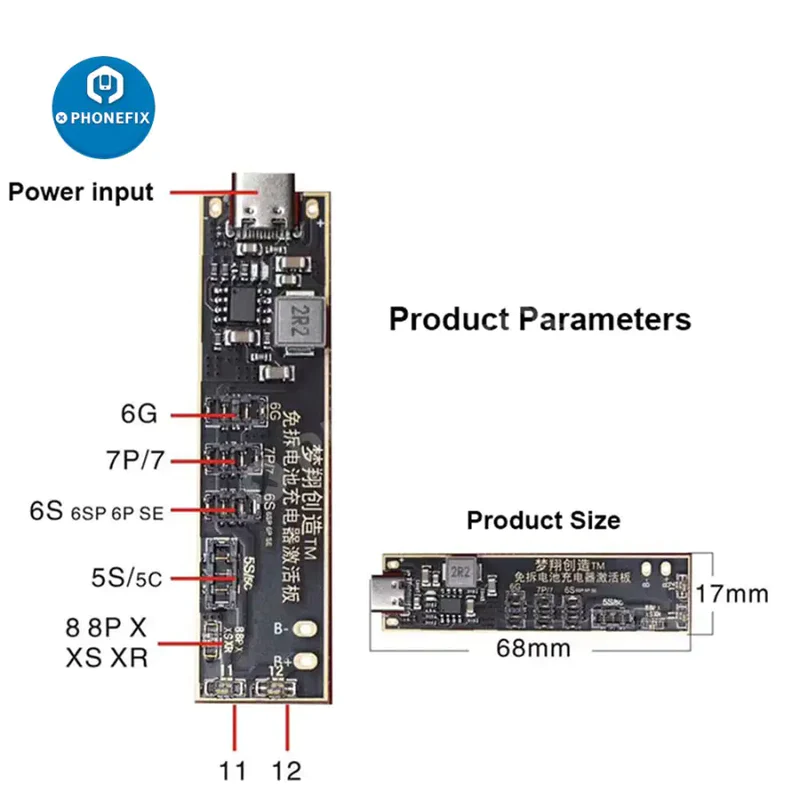

| C-001 Fast Charging Battery Activation Board For iPhone Battery | C-001 Smart Charger Battery Activation Board For iPhone 5S-12 Pro Max Charging Plate Support 1A 2A 3A Charge No Need Disassemble.OSS W223 Pro V6 ba... | |

| 2UUL Vajra Screen Separation Wire For Phone Repair 0.035mm | 2UUL DA21 Vajra Wire Screen Separation line 0.035MM*100M. 0.035mm High Hardness Tough Carbon Steel LCD Screen Separating Wire Flexible High Tensile... | |

| ICFRIEND MiPi NB Max Tester Box Emmc UFS Chip Programmer | Original ICFRIEND Mipi Nb Max box + UFS 4 in 1 Socket UFS BGA 153,UFS 254,UFS 297 Adapter + E-MATE eMMC 13 in 1 Adapter. MiPi NB-Max is a tool inte... | |

| SPAM2 Engineering Cable Enter Purple Screen For Apple Watch Repair | SPAM2 cable for usage with S0 on MagicAWRT Spam2 Cable Identification For iPad / iPhone 6S-X Engineering Line Enter Purple Screen Can OperationSeri... | |

| MECHANIC 3D Middle Layer BGA Reballing Stencil for iPhone X A12 | Mechanic 3D stencil for iPhone X motherboard middle layer soldering repair. Mechanic 3D-X-PRO middle layer stencil with positioning base for iPhone... |