High Quality Nine Foot Pallet Mould

Designing and manufacturing a Nine Foot Pallet Mould is a meticulous process that demands a deep understanding of industrial requirements, material properties, and cutting-edge technologies. Nine Foot Pallets are essential components in the logistics and shipping industries, serving as the foundation for transporting goods efficiently and securely. Creating a mould capable of producing high-quality, durable, and standardized pallets involves several key considerations.

1. Material Selection:

The choice of materials for a Nine Foot Pallet Mould is paramount. High-quality steel alloys, such as P20 or H13, are commonly utilized due to their excellent durability and resistance to wear. These materials can withstand the pressure and abrasion of the injection moulding process, ensuring the mould's longevity and consistent performance over numerous production cycles. The careful selection of materials is fundamental to creating pallets that meet industrial standards for strength and reliability.

2. Design Precision:

Precision in mould design directly translates to the quality of the pallets produced. Engineers employ advanced computer-aided design (CAD) software to meticulously plan every aspect of the Nine Foot Pallet Mould. This includes designing the mould cavities, runners, and cooling channels with utmost precision. The goal is to create a mould that allows for the seamless flow of molten material, ensuring uniformity and strength in the final pallets. Precision design also accounts for features like reinforcement ribs and load-bearing structures, crucial for the pallet's durability and weight-bearing capacity.

3. Efficient Cooling Systems:

Proper cooling is essential during the injection moulding process to prevent deformities and ensure consistent quality in the pallets. Engineers strategically design cooling channels within the mould to dissipate heat effectively. The utilization of advanced cooling techniques, such as conformal cooling, ensures uniform cooling rates across the moulded pallets. Maintaining consistent temperatures is vital to prevent warping, shrinkage, or stress cracks, guaranteeing that each pallet meets the required specifications.

4. Surface Finish and Texture:

The surface finish of the pallet mould plays a significant role in the appearance and functionality of the final product. Smooth and polished mould surfaces contribute to the aesthetic appeal of the pallets and simplify the demoulding process. Additionally, texture and patterns can be incorporated into the mould design to enhance grip and prevent slippage of goods during transportation. The careful consideration of surface finish and texture ensures that the pallets not only meet industrial standards but also serve their practical purpose effectively.

5. Automation and Advanced Technologies:

The integration of automation and advanced technologies optimizes the production process of Nine Foot Pallet Moulds. Automated moulding machines enhance efficiency, reduce labor costs, and improve consistency in pallet quality. Additionally, technologies like mold flow analysis software simulate the injection moulding process, allowing engineers to identify potential issues and optimize the design before physical production begins. By embracing these innovations, manufacturers can create moulds that produce pallets with superior quality and dimensional accuracy.

In summary, the design and production of a Nine Foot Pallet Mould Manufacturer necessitate a meticulous approach that encompasses material expertise, precision in design, efficient cooling systems, attention to surface finish, and the integration of advanced technologies. By adhering to these principles, manufacturers can produce moulds that consistently yield high-quality pallets, meeting the demands of modern industrial applications. The utilization of durable materials, coupled with advanced design and manufacturing techniques, ensures that the resulting pallets are robust, reliable, and capable of withstanding the rigors of industrial transportation and logistics.

在线联系供应商

Other supplier products

| heavy duty hand grease gun 900CC | 1.Capacity 900cc,double working time than usual type:Easily operated Heavy Duty Lever Handle ,working pressure 4500psi-12000psi.2.Two air rel... | |

| chinadirect.com | Ferrite block magnets(), also known as ceramic block magnets, are versatile and widely used permanent magnets known for their excellent magnetic pr... | |

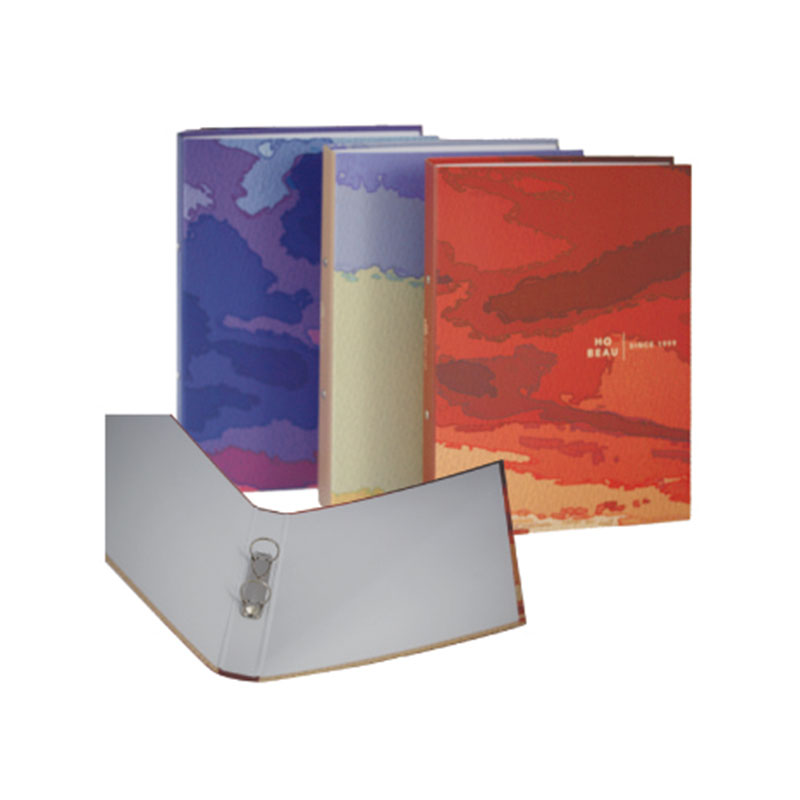

| Cardboard File Folder Storage Organizer | 我们的纸板文件夹存储整理器的结构设计经过精心设计,以提高可用性和耐用性。该整理器采用加固边缘和坚固结构,即使频繁使用也能保持其完整性。分隔板和隔间的加入进一步增强了整理功能,可以高效地对文件进行分类和检索。此外,可折叠设计确保不使用时方便存放,从而优化工作空间内的空间利用率。 < ; | |

| 4SK-100 Deep Well Pump | Deep Bore Pumps are engineered marvels designed to access and extract water from deep underground sources. These robust pumps are the go-to solutio... | |

| Scraping Knife With Flat Wooden Handle | SIZE: 10 " MEAS(CM): 52x34x34 PACKING QTY(PCS): 10/50 G. W/N.W(KG): 16/14 |

Same products

| Micronized polypropylene wax for injection moulding | 卖方: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | 卖方: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |