Nylon is commonly referred to using the chemical designation “PA” (e.g., PA 6 or PA 6/66) and is most widely available in black, white, and its natural color (off-white or beige). Perhaps the most com

Nylon is commonly referred to using the chemical designation “PA” (e.g., PA 6 or PA 6/66) and is most widely available in black, white, and its natural color (off-white or beige). Perhaps the most common variant for engineering applications is Nylon 6/6. Nylon 6/6 can be extruded (melted and forced through a die) and is also a suitable plastic for both injection molding and 3D printing. It has a high melting temperature, making it an excellent substitute for metals in high-temperature environments (e.g., under the hood of a vehicle). The material’s downside is that it has relatively low-impact strength (even when compared to other plastics). Of note, the impact strength of Nylon can be improved by a process called “conditioning.” For this reason, as well as the ease with which Nylon can be combined with other materials to enhance its strength, it is important to check the material properties of the specific Nylon material you are using.

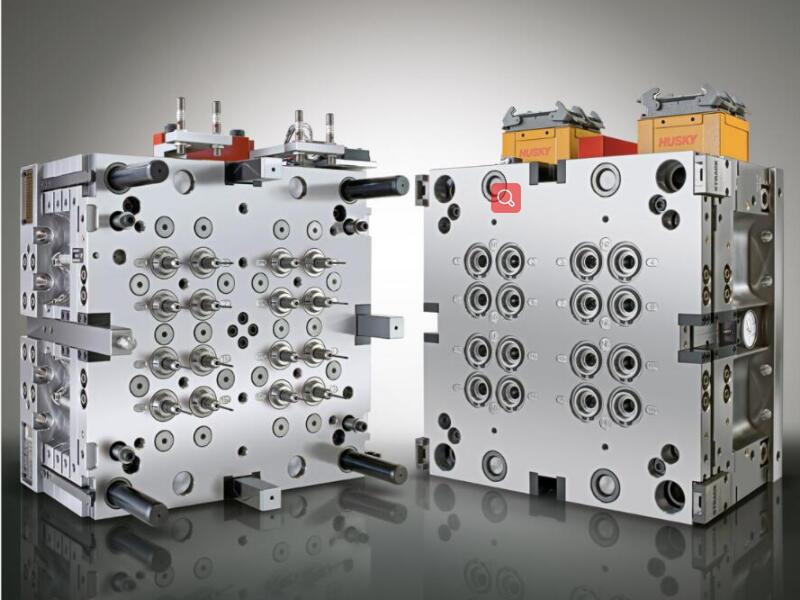

The molding cycles are quick, providing an economical interest. Polyamide 6 and Polyamide 66 answer the requirements of numerous applications in the varied markets. PA6, PA66 Replace Metal in Automotive Applications Electrical & Electronics Applications-Flame Retarded PA Works Well! Good Surface Aspect in Consumer Applications Food Packaging with PA6 PA66.

Properties of Nylon Injection Molding

High mechanical strength, good toughness, and high tensile and compressive strength.

The fatigue resistance is outstanding, and the parts can still maintain the original mechanical strength after repeated repeated bending.

High softening temp. and heat resistance.

Smooth surface, low friction coefficient, wear-resistant.

Has excellent electrical properties.

Self-extinguishing, non-toxic, odorless, good weather resistance, inert to biological erosion, good antibacterial and anti-mildew ability.

The parts are light in weight, easy to dye and easy to form. Because of its low melt viscosity, it can flow quickly for easy filling.

Nylon Injection Molding Requirement

Drying Temperature 60-80 °C

Drying Time 4.0-6.0 hr

Suggested Moisture Content <=0.30 %

Rear Barrel Temperature 180-220 °C

Middle Barrel Temperature 200-220 °C

Front Barrel Temperature 220-260 °C

Nozzle Temperature 230-260 °C

Mold Temperature 60-80 °C

We are plastic injection mould inc,we provide nylon plastic injection molding,can nylon be injection molded,nylon molding,plastic injection moldingand plastic injection.

在线联系供应商

Other supplier products

| PC Injection Molding | PC is classified as a ''thermoplastic'', and the name has to do with the way the plastic responds to heat. Thermoplastic materials become liquid at... | |

| PVC Injection Molding | Polyvinyl Chloride (PVC or Vinyl) is a high strength thermoplastic material widely used in applications, such as pipes, medical devices, wire and c... | |

| Medical Plastic Injection Molding | Feman medical parts are essential component of Feman tooling. There is special department in-house that only service for the medical customers. A t... | |

| Acrylic Injection Molding | Acrylic is a transparent thermoplastic homopolymer known more commonly by the trade name “plexiglass.” The material is similar to polyc... | |

| Automotive Plastic Injection Molding | Feman automotive mouldis the automotive mould projects and technical development & manufacturing foundation of Femanplastic injection factory. ... |

Same products

| Crushed tofu cat litter | 卖方: DALIAN ZZ INT'L TRADE CO.,LTD. | Crushed tofu cat litter Our crushed tofu cat litteris suitable for automatic cat litter boxes.Ir... | |

| Cylinder natural tofu clumping cat litter | 卖方: DALIAN ZZ INT'L TRADE CO.,LTD. | Cylinder natural tofu clumping cat litter High-quality natural materialsAbsorbs water in one sec... | |

| Thick paper cat litter | 卖方: DALIAN ZZ INT'L TRADE CO.,LTD. | Thick paper cat litter Eco-friendlyLightweightFlushableLow tracking and low dustWill not grow mo... | |

| Natural cypress cat litter | 卖方: DALIAN ZZ INT'L TRADE CO.,LTD. | Natural cypress cat litter Eco-friendlyLightweightFlushableLow tracking and low dustWill not gro... | |

| 2UUL DA35 磁吸式摄像头保护盖,含4个不同尺寸的镜头防尘盖 | 卖方: Phonefix | 2UUL DA35 磁吸式摄像头保护盖包含4个不同尺寸的保护盖,可保护各种手机摄像头。磁吸式设计,安装和拆卸便捷,有效防止手机后置摄像头镜头受损,并在维修过程中阻挡灰尘或碎屑。适用于各种手机维修... |