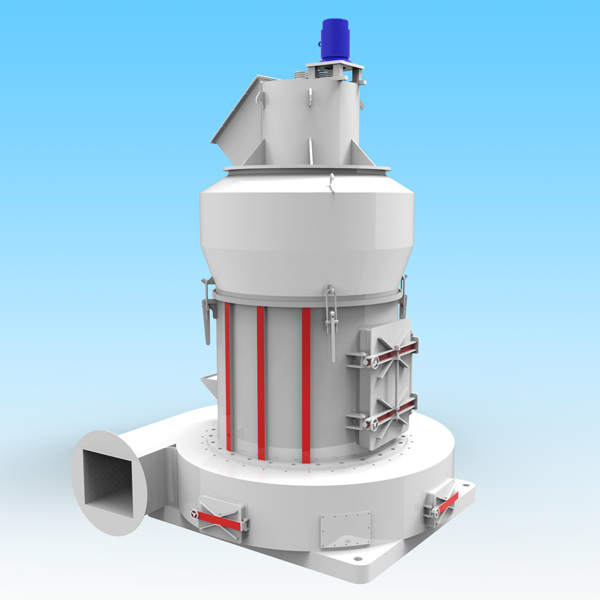

Pendulum Grinding MillPendulum Grinding Mill

Pendulum Grinding Mill

Pendulum mill is also called as suspension roller or Raymond mill. It is a "ring and roller" powder-making mill equipment, which is combined with air flow screening and pneumatic conveying. The pendulum grinding mill belongs to the roundel immovable mill and has high universality. It also has the characteristics of continuous powder making dry-type, the concentration of grain size, continuous fine fineness, compact structure and so on. The particle size of the pendulum grinding mill can be adjusted in the range of 0.125-0.044mm (equivalent to 120-325 mesh) according to different requirements.

The Application Ranges of the Pendulum Grinding Mill

The Pendulum Grinding Mill is widely used. Common grinding materials and usage ways are as follows:

Soil types: clay, China clay, bentonite, magnesia, clay, bauxite, etc.

Non-metallic ores: gypsum, talc, graphite, fluorite, calcite, limestone, calcite, barytes, apatite, tabular spar, feldspar, quartz and so on.

Metal oxides: manganese iron ore, chromite, Ilmenite, bauxite and so on.

Chemical compounds: coke, lime coke, smelting coke, barium sulfate and so on.

Others: the products of the pendulum grinding mill can be used in many industries. For example, the metallurgical industry produces the magnesia as the refractory layer of blast furnace; the oil industry uses the barytes powder to seal the injector; some industries produce bentonite powder as the lubricant for drilling; the chemical industry produces different stone powder as the filler in rubber, plastics, paper making and paint; porcelain, glass, enamel, white cement, gypsum and magnesia products are all processed by pendulum grinding mill.

The pendulum grinding mill is mainly used for grinding non-inflammable and explosive mineral materials, Moh’s hardness of which is below 7 level and humidity of which is below 6%.

Operation Principle of the Pendulum GrinderMill System

The bulk material is broken by the Jaw crusher to a certain size (powdery or fine particles can not pass through the Jaw crusher), and the material is conveyed vertically to the hopper by a bucket elevator. Then, the electromagnetic vibration feeder delivers the materials quantitatively, evenly and continuously into the main machine for grinding. The pulverized fines are carried out by the blower’s airflow and graded by an analytical machine placed above the main engine. Suitable fine powder that meets the requirements will be entered into the large cyclone separator with the air flow. After separation, the powder will be discharged through the discharge pipe, that is a qualified product. The air flow enters the blower by the return duct at the upper end of the cyclone separator. The whole airflow system is closed loop and operates under negative pressure. Because the grinding material contains moisture, when milling the moisture will evaporate into gas. That gas then leaks in each connection of the whole pipe, which makes an increase in the volume of air in the circulating air stream.

This increased air volume will be introduced into the small cyclone separator from the air duct between the blower and the main engine. The fine powder with the air flow is collected by the small cyclone separator. Then it will be discharged by another outlet pipe. The gas will be discharged into the atmosphere through the exhaust pipe of the upper end of the small cyclone separator.

在线联系供应商

Other supplier products

| GK-PSC Type Water Spray Precipitator | This equipment is one of the necessary equipment for the lime digester. GK-PSC Type Water Spray Precipitator characters: It adopts natural water c... | |

| Impact Crusher | The Application and Usage of Impact Crusher: Impact crusher is suitable for materials whose compressive strength is under 350Mpa, and particle size... | |

| GK2150 Raymond Mill | GK2150 Raymond Mill Technical & Structural Benefits: This High Pressure Suspension Millhas high output, high-efficiency, and energy saving. It ... | |

| Raymond Mill | As national powder R&D center, GUIKUANG has made much efforts and contributions for the development of powder industry more than 40 years. Raym... | |

| Crusher Machine | GUIKUANG offers mobile stone crusher machinewhich can be used to crush all kinds of ores and rocks with compressive strength below 250Mpa. It is su... |