PU/PIR Continuous Sandwich Panel Production Line

Continuous PU Sandwich Production Line, also calledpolyurethane sandwich panel manufacturing linemachine, is an automatic production line, which is consisting of decoiler, film coating, pre-cutting, cutting equipment, roll forming system, preheating, foaming, solidification, band saw cutting, cooling, stacking and packing. The wholepu sandwich panel line/PIR sandwich panel production lineintegrates technologies of mechanics, chemistry, electrical control, hydraulic pressure pneumatic and temperature control.

Jinggong has been specialized in providing high-quality PIR/PU sandwich panel production line, feel free to contact us forPIR/PU sandwich panel production line price!

Main Technical Parameters of PU/PIR Continuous Sandwich Panel Production Line

|

Item |

Parameter |

|

|

Material |

Type |

Color steel sheet; galvanized sheet, Aluminum sheet |

|

Thickness |

||

|

Width |

≤1250(Max) |

|

|

Suitable size of panel |

Length |

2000-16000 |

|

Width |

600-1200 |

|

|

Thickness |

30-200 (Not including height of corrugation) |

|

|

Production speed |

3-8 (Adjustable) |

|

|

Valid length of double belt conveyor(mm) |

||

|

Work pressure on pouring foam |

150-200 |

|

|

Total power |

About 300 |

|

|

Total size(Length×Width×Height)(mm) |

130000×15000×6000 |

|

Features of PU/PIR Sandwich Production Line

- Beautiful and applicable, multiple functions, such as thermal isolation, sound isolation and flame retardance.

- Using heated air recycle oven, strictly control the temperature of PU foaming and solidification in suitable range.

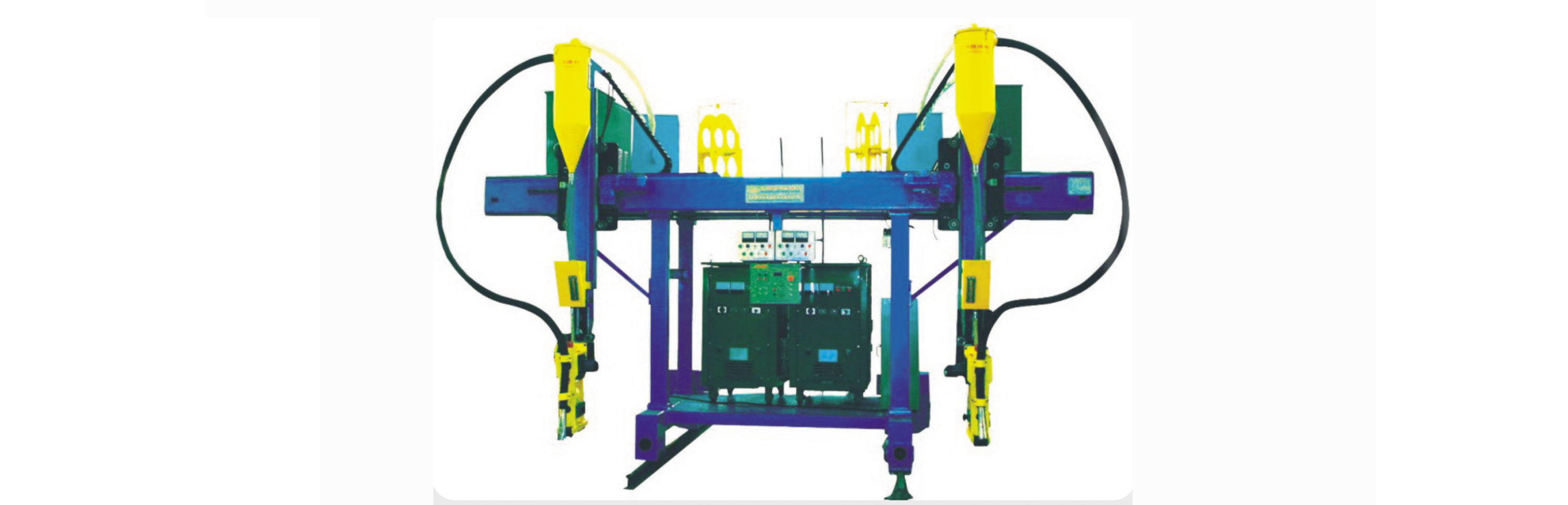

- Using high-pressure foaming system, precise measurement, high stability, little dust in the locale, protect the worker's health.

- Using 141B or Pentane as foaming agent. Instead of carbon chloral-fluoride, make the PU foaming treatment become an environmental production craft.

- Special double belt conveyor, flat surface of sandwich panel, even thickness, anti-pattern

- Operation system controlled by PLC computer, personal design and simple operation.

Panel Drawings Of PU/PIR Continuous Sandwich Panel Production Line

Working Process Layout Of PU/PIR/Rockwool Sandwich Panel Production Line

Decoiling System

Decoiler transverse location---Lifting stage move outside---coil hoisting—lifting stage move inside---Lifting stage rise----Lifting stage car move to inside position---Decoiler axle expanding (---Pressing-arm press tightly)----Lifting stage reset position---decoiler uncoiling material

Filming Slitting And Cutting

Filming the plastic film on the panel surface.

The pre-cutter is used for cutting the single skin panel when it needs to change to be another profile.

Roll Forming System

There is one set roll forming machine for upper layer profiles. That is double head roll forming machine.

The upper roll forming machine consists of two sets of forming rollers, one set of guiding system, one set of the transmission system, one set of frame.

Rockwool System

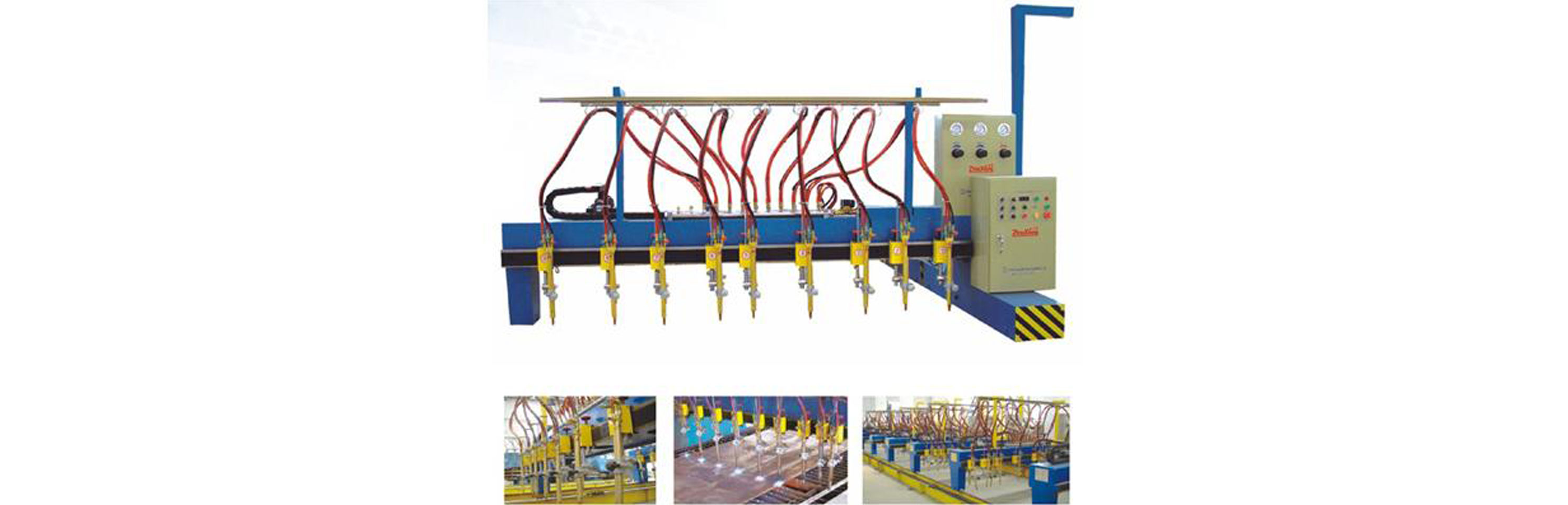

The rock wool system consists of rock wool lifting device, rock wool slitting device rock wool turning device, upper and lower foam spraying system, two components side sealing foaming machine, dust collecting device and conveyor, etc.

Pre Heating

Preheat the oven-----Adjust the temperature-----panel forwards-----Send panel into the oven-----Guiding roller transmission-----Measure the temperature of panel----Sent panel out of the oven

Foaming Accessories

Accessories of foaming system include sheet transmission conveyor, adhesive tape sealing device, sponge sealing device.

Double Belts System

DBL is mainly used to overcome the expansibility of foaming and make it solid, and decide panel thickness and production speed. Side belt is overcome horizontal expansion and decide the width of panel and guiding to the panels.

Bandsaw Cutting System

Motor power: 5.5kw

Motor power for band saw moving: 1.5kw

Max panel thickness: max. 250mm

Cutting distance: max.1200mm

Total power: 20 kw

Cooling System

The cooling system consists of front and back conveyor, two sets of lifting belt conveyor, cooling processing conveyor and electric system.

Stacking System

There are sensors equipped on the front conveyor, two panels can be stacked at the same time if the length is less than 7.5m; one panel can be stacked if the length is more than 7.5m.

Packing System

It mainly consists of conveyor roller and packing machine.

The wrapping device of packing machine is driven by a reducer motor, adopts gearwheel and toothed bar driving structure to rotate quickly to cover the film on the surface of products.

Electrical Control System

Electric system is included in the machines.

Jinggongis a professional purlin roll forming machine manufacturers, we provide pir sandwich panel machine, wall panel machine,polyurethane sandwich panel machine, building materials machinery, pu sandwich panel machine china, sandwich panel linesand etc. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| How to Choose a Good Wall Panel Machine Manufacturer? | 2021-03-05 Since the new wall panel market is very popular now, the wall panel machineindustry is full of many manufacturers. Facing many wall pan... | |

| H Beam Shot Blasting Machine | Hbeam shot blasting machineis designed and manufactured to clean the surface of the section steel. It is ideally suited for removing the rust, scal... | |

| Gantry Submerged Arc Welding Machine | Thegantry welding machinecan replace the cantilever submerged gantry weldingmachine, and can choose unipolar or multipolar welding, the landfill hi... | |

| CNC Flame Cutting Machine | The cnc flame cutting machineis a multifunctional thermal auto-cutting device combined microcomputer controlling, precise machinery and oxygen-acet... | |

| Roll Forming Machine | Having made automatic rollforming equipmentfor over twenty years, we are a professional roll forming machine supplierin this area with rich experie... |

Same products

| Floral Garden Tools Set | 卖方: Dongyang Guorui Industry And Trade Co., Ltd. | Investing in a floral garden tools set not only enhances your gardening experience but also add... | |

| 希腊-小型气相液氮储存罐-液氮容器 | 卖方: 河南天之道生物科技有限公司 | 在科技不断进步的今天,随着现代科研和医疗领域对生物样本的低温保存要求越来越高,小型气相液氮罐的出现,成为这一领域的理想选择。下面KGSQ厂家为您具体介绍一下它的优势特点。 1.气相/液相储存 小... | |

| Common Rail FuCommon Rail Fuel Injector Nozzle L500PBCel Injector Nozzle L500PBC | 卖方: 738347 | Common Rail Fuel Injector Nozzle L500PBC 0 445 110 189 Injector Valve Set 0 445 110 190 Injector... | |

| 匈牙利-小型气液相液氮罐-液氮容器 | 卖方: 河南天驰仪器设备有限公司 | 在科技不断进步的今天,随着现代科研和医疗领域对生物样本的低温保存要求越来越高,小型气相液氮罐的出现,成为这一领域的理想选择。下面KGSQ厂家为您具体介绍一下它的优势特点。 1.气相/液相储存 小... | |

| 波兰-小型气相液氮罐-气相储存容器 | 卖方: Henan Tianzhidao Biological Technology Co., Ltd. | 在科技不断进步的今天,随着现代科研和医疗领域对生物样本的低温保存要求越来越高,小型气相液氮罐的出现,成为这一领域的理想选择。下面KGSQ厂家为您具体介绍一下它的优势特点。 1.气相/液相储存 小... |