Sheet Metal Stamped Components

Sheet Metal Stamped Components

Basic Info.

Trade Term: EXW,FOB,CIF.CFR

Payment Term: T/T,L/C, Western Union

Delivery Time:7-30days

Place of Origin: Ningbo, China

Sheet Metal Stamped ComponentsSheet Metal Stamped ComponentsSheet Metal Stamped Components

Information About HEWCHO Sheet Metal Stamped Components

Features of sheet metal stamping dies:

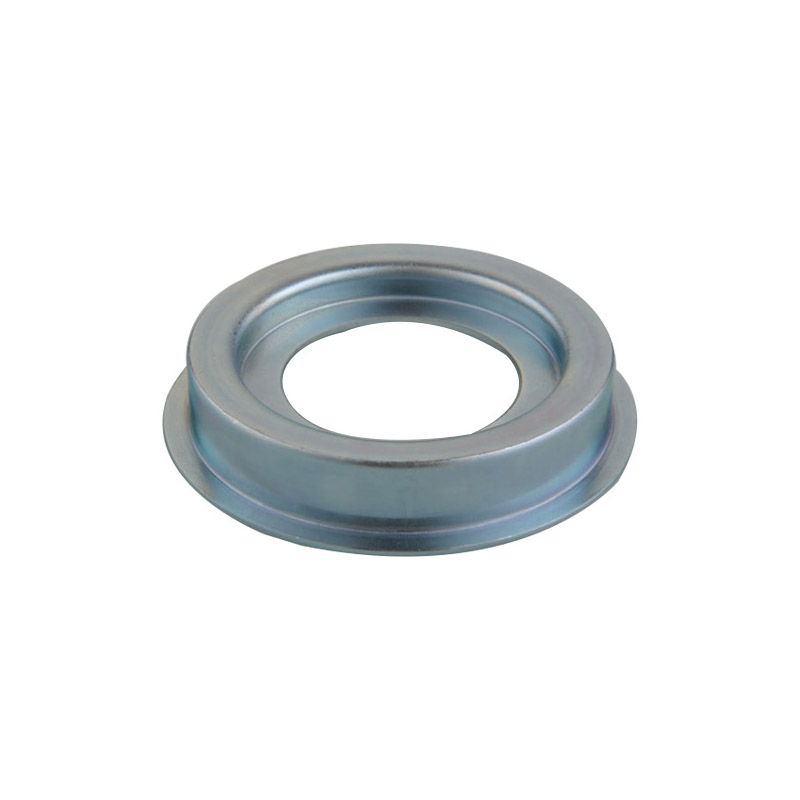

·Product name: Sheet Metal Stamped Components

·Material:Carbon Steel, Barss, Copper, Stainless Steel, Alumnum, Titanium Alloy

·Machining Tolerances:0.1mm

·Machining Process:

Punching, edging, pressing and welding

·Min. Order:1000PCS

·Surface Treatment: Polishing, Heat Treatment, Sand Blasting, Zinc Plated, Anodization, Chemical Fim,

·Packing: Carton Box, Blister tray, Pallet, Wooden Case.

·Certificate:ISO9001:2008, ISO/TS16949

As a stamped components supplier, we provide custom metal stamping die and stamping sheet metal parts for sale.

metal-stamping-partsprecision metal stamping partsheet-metal-stamping components

What we can Provide:CNC Turning ServiceMachining Material:Stainless Steel

CNC Machining ServiceCarbon Steel

CNC Turning ServiceStainless Steel

CNC Milling ServiceAluminum

Cold Forging ServiceBrass

Metal Stamping ServiceCopper

Titanium Alloy

Surface TreatmentSurface TreatmentApplication:Automobile Spare Parts

Heat TreatmentAutomobile Spare Parts

Sand BlastingElectrical Appliance Industry

PolishingElectronics Industry

Zinc PlatedGeneral Industry

AnodizationMachinery and Equipment

Chemical FimHydraulic and Pneumatic

Sheet Metal Stamped Components 2 Sheet Metal Stamped Components 3 Sheet Metal Stamped Components

Description of stamping sheet metal parts

Sheet metal stampings are products made of thin sheets such as aluminum, steel or stainless steel and are usually produced in large quantities. The production is economical and environmentally friendly, since in contrast to other methods, the machining is done mechanically and thus energy-saving without thermal influence of the sheet material. Another feature of these stamped sheet metal parts is an optimal dimensional accuracy even with large quantities, which is ensured by the use of high-quality punching tools. Typical application examples are semi-finished products for assemblies, recesses, countersinks, gills, lugs and many more.

With a large selection of punching tools and state-of-the-art technology, Ningbo hewcho can produce custom metal stamping die with any shape to your specifications, cost-effectively . Especially for production orders with recurring shapes, CNC punching of sheet metal is the optimal manufacturing solution. All common sheet metal formats can be punched and folded up to a material thickness of 8 mm . Upon customer request, complete machining for ready-to-install components is no problem.

How is the punching of sheet metal done?

Sheet metal is stamped on NC-controlled punching nibbling machines. Our suppliers have an extensive range of punching tools available, which consist of a punch and die and precisely fit into each other. During the machining process, the metal sheet is fixed firmly on the machine table and guided precisely under the punching tool. This separates with rapid successive strokes the sheet material until the desired stampings are cut out of the sheet.

Ningbo Hewcho Industrial is one ofexperiencedturned parts suppliers, we provide CNC turning parts, CNC milling parts, hydraulic cylinder rodand etc. Want to know mmore? Please contact us.

在线联系供应商

Other supplier products

| Swiss CNC Turning Components | Basic Info. Trade Term: EXW,FOB,CIF.CFR Payment Term: T/T,L/C, Western Union Delivery Time:7-30days Place of Origin: Ningbo, China Swiss CNC Turnin... | |

| Cold Forging Rivets | Basic Info. Trade Term: EXW,FOB,CIF.CFR Payment Term: T/T,L/C, Western Union Delivery Time:7-30days Place of Origin: Ningbo, China Information Abou... | |

| Pump Spare Parts | Description of pump components Ningbo Hewcho is a manufacturer of precision custom machining components. We can also offerpump spare partswhich nee... | |

| Metal Sheet Stamping Brackets | Basic Info. Trade Term: EXW,FOB,CIF.CFR Payment Term: T/T,L/C, Western Union Delivery Time:7-30days Place of Origin: Ningbo, China Metal Sheet Stam... | |

| Stainless Steel CNC Machining Parts | Features ofstainless steel machined parts: ·Product name:Stainless Steel CNC Machinng Parts·Material:Stainless Steel 303, 304, 316&mi... |

Same products

| Floral Garden Tools Set | 卖方: Dongyang Guorui Industry And Trade Co., Ltd. | Investing in a floral garden tools set not only enhances your gardening experience but also add... | |

| 希腊-小型气相液氮储存罐-液氮容器 | 卖方: 河南天之道生物科技有限公司 | 在科技不断进步的今天,随着现代科研和医疗领域对生物样本的低温保存要求越来越高,小型气相液氮罐的出现,成为这一领域的理想选择。下面KGSQ厂家为您具体介绍一下它的优势特点。 1.气相/液相储存 小... | |

| Common Rail FuCommon Rail Fuel Injector Nozzle L500PBCel Injector Nozzle L500PBC | 卖方: 738347 | Common Rail Fuel Injector Nozzle L500PBC 0 445 110 189 Injector Valve Set 0 445 110 190 Injector... | |

| 匈牙利-小型气液相液氮罐-液氮容器 | 卖方: 河南天驰仪器设备有限公司 | 在科技不断进步的今天,随着现代科研和医疗领域对生物样本的低温保存要求越来越高,小型气相液氮罐的出现,成为这一领域的理想选择。下面KGSQ厂家为您具体介绍一下它的优势特点。 1.气相/液相储存 小... | |

| 波兰-小型气相液氮罐-气相储存容器 | 卖方: Henan Tianzhidao Biological Technology Co., Ltd. | 在科技不断进步的今天,随着现代科研和医疗领域对生物样本的低温保存要求越来越高,小型气相液氮罐的出现,成为这一领域的理想选择。下面KGSQ厂家为您具体介绍一下它的优势特点。 1.气相/液相储存 小... |