Roof/Wall Panel Roll Forming Machine

Production of roof and wall panel roll forming machinefrom Hangzhou Roll Forming Technology Co., Ltd is dignified and elegant, beautiful and novel, and the appearance of level off, even ripple, high utilization rate, strength, high production automation, low cost. Among all roof panel roll forming machine manufacturers, we provide all kinds of standard and non-standard wall panel roll forming machines: Roof Tiles Manufacturing Machine, Box Profile Roofing Sheet Roll Forming Machine, Corrugated Sheet Roll Forming Machine, Roofing Tile & Glazed Tile Making Machine, High-Speed Roofing Tile Making Machine, Metal Roof Tile Making Machine, AG Panel Roll Former, AG Panel Roll Former, Gutter Roll Former, Interlocking panel forming machine, etc.

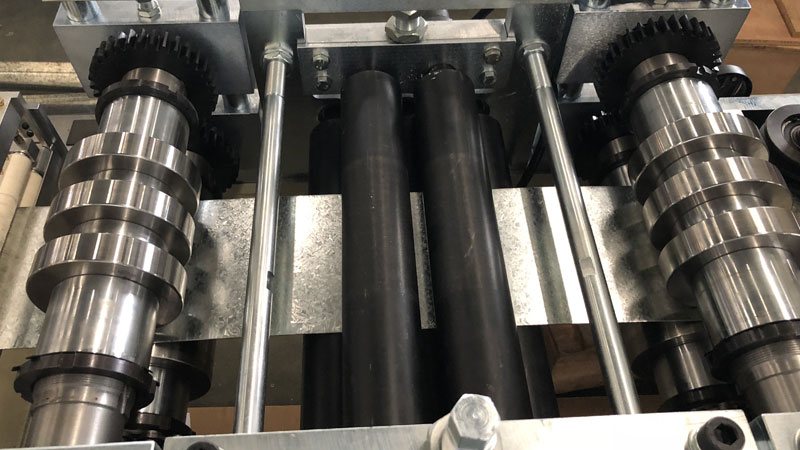

Roof and wall panel roll forming machineComponents Detail

|

Metal Decoiler |

Cantilevered TypeHydraulic ExpandingzHydraulic ReleasingWith Light controlSeparate Hydraulic station and control |

|

Guiding device |

Adopting a guiding bar and sliding block to control the width and position of the steel sheet. The sheet is guided in the correct position and runs to the roll forming equipment. |

|

Roll Forming System |

|

|

Punching die and Cutting Device |

|

|

Product Supporter |

To support the finished panels manually and the length of each piece is 2 meters, two pieces. |

|

Electrical Control System |

With PLC control and frequency speed adjusting technology to realize the automatic production1. The system provides a good interface screen for the roof forming machine, which can set the batches, plate length, and quantities. |

|

Hydraulic Station |

|

Roof And Wall Metal Roof Tile Making Machine FAQs

How thick plate can your panel roll forming machineforming?

Normally the thickness of roof/wall panel form 0.23mm to 1mm. If customers want to make thicker panel, we can also design the machine.

What kind of roofing panel can your roof panel machinemake?

Our roll forming line make trapezoidal panel, corrugated panel, stand seam panel, metal roof tile, AG panel, PBR panel, ridge capping and so on. We also design and manufacture rolling line according customers' profile drawings.

Are your panel forming machine in stock?

We have some popular rolling machines in stock. It takes about 45 days if customers need customize machines.

Can you make metal roof tile making machine according to customers' profile drawings?

We can design and manufacture metal roof tile making machine according customers' profile drawings. It takes about 45 days if customers need to customize machines.

Can your roof panel machine forming aluminum panel?

We can design and manufacture rolling line for aluminum panel.

Hangzhou Roll Forming Technology Co., Ltd is af professional coil upender manufacturers, we provide steel coil upender, coil upender for sale, upender machine, recoiler machine, metal panel machine, pipe mill for saleand etc. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| C Purlin Roll Forming Machine | TheC purlin roll forming machineproduced by Hangzhou Roll Forming Technology is manufactured with advanced technologies. Not only does this series ... | |

| Recoilers | Recoileris the recoiling part of the slitting line. The recoiler machineturns raw materials into coils by mechanical means. The recoiler is widely ... | |

| Roofing Tile/Glazed Tile Making Machine | Roofing Tile & Glazed Tile Making Machine is for continuously roll forming and pressing step tiles sheets. The step length of this glazed roof ... | |

| Guardrail Roll Forming Machine | The highway guardrail is the main form of the semi-steel guardrail. It is a continuous structure in which corrugated steel guardrails are spliced t... | |

| Guardrail Roll Forming Machine | The highway guardrail is the main form of the semi-steel guardrail. It is a continuous structure in which corrugated steel guardrails are spliced t... |