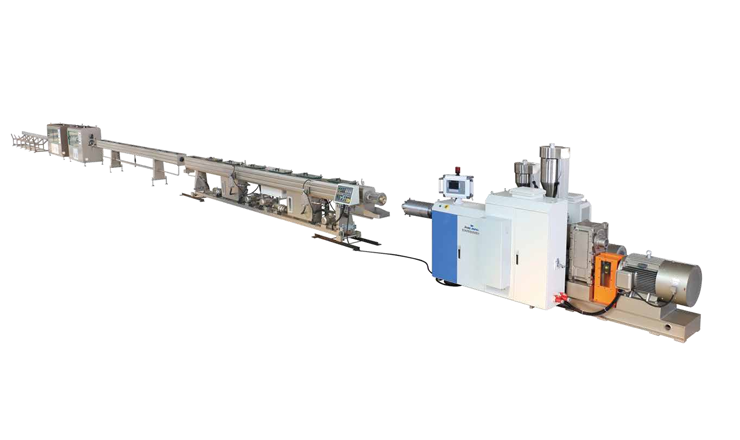

HDPE Blow Molding Machine

JWELL Extrusion Machinery Co., Ltdis one of the leading hdpe blow molding machine manufacturersand blow molding machine suppliersin China. The HDPE blow molding machine, also called HDPE blow moulding machine, is mainly used for processing unsupported parisons. The advantages of HDPE moulding machine are high production efficiency, low equipment costs, wide selection of molds and machinery, and the hdpe blow molding machinedisadvantages are high scrap rate, waste recycling, Poor utilization, the thickness control of the product during hdpe blow molding machine process, and the dispersibility of the raw materials are restricted, and trimming operations must be performed after molding. Contact us for the HDPE blow moulding machine price!

Description about HDPE Blow Molding Machine

|

Item |

Description |

|

Place of origin |

China |

|

Brand name |

JWELL |

|

Model number |

HDPE Material |

|

Minimum order quantity |

5L |

|

Packaging details |

Wooden pallet packing |

|

Delivery time |

90days |

|

Payment terms |

Specifications of HDPE Blow Molding Machine

|

HDPE hdpe blow moulding machine TechnicalDetails |

||||

|

Model |

Unit |

BM30 |

BM50 |

BM100 |

|

Maxproductvolume |

L |

30 |

50 |

100 |

|

Drycycle |

Pc/h |

600 |

450 |

360 |

|

Dieheadstructure |

Accumulatingtype |

|||

|

Mainscrewdiameter |

mm |

80 |

90 |

100 |

|

Maxplasticizingcapacity(PE) |

kg/h |

120 |

180 |

190 |

|

Drivingmotor |

Kw |

37 |

45 |

55 |

|

Accumulatingvolume |

L |

|||

|

Oilpumpmotorpower |

Kw |

15 |

22 |

|

|

Clampingforce |

KN |

280 |

400 |

600 |

|

Spacebetweenplaten |

mm |

400-900 |

450-1200 |

500-1300 |

|

PlatensizeW*H |

mm |

740*740 |

880*880 |

1020*1000 |

|

mm |

550*650 |

700*850 |

800*1200 |

|

|

Heatingpowerofdiehead |

Kw |

20 |

28 |

30 |

|

MachinedimensionL*W*H |

m |

|||

|

Machineweight |

T |

12 |

16 |

|

|

Totalpower |

Kw |

95 |

110 |

135 |

|

Note:Informationslistedaboveareforreferenceonly,theproductionlinecanbedesignedbycustomer’srequirements. |

||||

HDPE Blow Molding Machine Application

Hdpe bottle blow molding machine is suitable for producing 15-30L different size Chemical packaing.

jerrycan, 15-100L different size jerrycan,open-top, barrels, and other chemical packaging products.

HDPE Blow Molding Machine Performance and Advantages

HDPE plastic blow molding machine manufacturers use Storage head, high-efficiency screw, bottom blowing Structure can be equipped with automatic flash removal, the product is on Line leak detection, weighing, conveying, flash online Conveying system to reduce labor costs, HDPE blow moulding machine price and increase Productivity.

Using B&R automation parison programmer, Support multi-task time-sharing operation, automatic High degree of chemistry; 400-point wall thickness control System, ATOS servo valve, parison Accurate thickness control.

The mold-moving frame adopts a tie-bar-less structure, which has the characteristics of uniform mold clamping, large clamping force, large modulus, and more convenient mold disassembly and assembly; mold movement, mold opening, and closing are controlled by a servo system and electronic ruler to achieve a gentle slope and silent sports.

If you want to know more about extrusion machine, please visit our website.

在线联系供应商

Other supplier products

| PE Sheet Extrusion Line | Jwell has the following products in the thick plate production line: PP thick plate production line Sheet from PP Thick Plate Extrusion Line ... | |

| PVC Sheet Extrusion Line | PVC Sheet Extrusion Line The PVC sheet extrusionof Jwell machinery chinais divided into hard sheet and plate, mainly as follows: There are tw... | |

| Pipe Extrusion Machine | JWELL Machinery is designed and developed in a new idea, pipe and profile extrusion line produces PP pipe series, PVC pipeline series, ABS pipeline... | |

| Extrusion Line | Here, you can learn about various JWELL extruder china and related components of extrusion line machines, such as sheet extrusion line, plate extru... | |

| PP Pipe Extrusion Machine | The series of PP pipe extrusion machine lines mainly extruded production: MPP power pipe, PPR, Pert, PEX, cold & hot water pipe, RB, PO, MULTI-... |