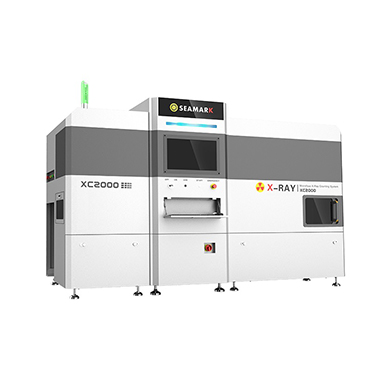

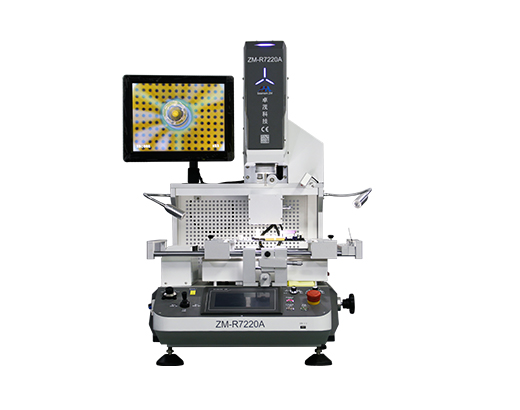

ZM-R7220A Infrared Soldering Station

ZMR7220Ainfrared SMD rework stationis an intelligent infrared soldering station with real-time temperature monitoring, optical alignment system, rapid heating, and cooling. As an iir soldering station manufacturer, Zhuomao promises to provide high-quality infrared BGAmachines. Significantly, Zhuomao's infrared soldering station price is reasonable. Plus, Seamark ZM-R7220A ir rework station is also called zhuo mao zm r6200cin the past.

Functions of R7220A Infrared Soldering Station (ZM R6200)

00Real-time Temperature Monitoring

Real-time temperature display, with automatic curve analysis function.

01Optical Alignment System

High-definition CCD (2m pixels) digital imaging, automatic optical zoom system, manual control and laser red-dot alignment.

02Rapid heating and cooling

The IR preheating zone is heated by a medium wave ceramic infrared heating plate, a multi-functional movable PCB fixing bracket, and a BGA bottom support frame. Laminar integrated cooling fan.

As one of the top infrared soldering station suppliers in China, Seamark ZM is famous for itsrich technicalforce, completedetectionmeans, reliableproductquality, andfullservice. If you want to know theBGA repair machineand to get a perfect infrared soldering station price for your factory, please contact Seamark ZM first.

Specification Of R7220A IR BGA Rework Station (ZM R6200C)

|

Power Supply |

AC220V±10% 50/60HZ |

|

Power |

|

|

PCB Size |

412*370mm(Max);6*6mm(Min) |

|

BGA Chip Size |

60*60mm(Max);2*2mm(Min) |

|

IR Heater Size |

285*375mm |

|

Temperature Sensor |

1 pcs |

|

Operation Method |

7" HD touch screen |

|

Control System |

Autonomous heating control system V2(software copyright) |

|

Display System |

15" SD industrial display (720P front screen) |

|

Alignment System |

2 Million Pixel SD digital imaging system, automatic optical zoom with laser red-dot indicator |

|

Vacuum Adsorption |

Automatic |

|

Alignment Accuracy |

±0.02mm |

|

Temperature Control |

K-type thermocouple closed-loop control with accuracy up to ±3℃ |

|

Feeding Device |

No |

|

Positioning |

V-groove with universal fixture |

|

Dimensions |

L685*W633*H850mm |

|

Weight |

76KG |

Difference Between A Hot Air Rework Station And An IR BGA Rework Station

The main difference between a hot air rework station and an IR BGA Rework Station is the way they heat the board. A hot air rework station uses heated air to transfer heat from the tool-to-board interface and into the solder balls, whereas an IR BGA Rework Station uses infrared light to heat up just enough of each ball so that it melts.

The next important difference is how they control temperature: Hot Air rework stations use PID temperature control, but IR BGA Rework Stations use proportional pressure modulation (PPM). PPM is more precise than PID because it can monitor changes in pressure within milliseconds. This means that when applying flux to a board or when reflowing solder balls on a board, you can rapidly respond by adjusting your PPM settings as necessary. With PID, this would take about 20 seconds per change due to slow response times in most systems.

Another key difference lies in airflow control systems; hot air has no need for specialized airflow since there's no need for cooling during reflow since all of that happens outside of the oven chamber using an external fan which blows across all areas equally regardless if they are close or far away from each other.

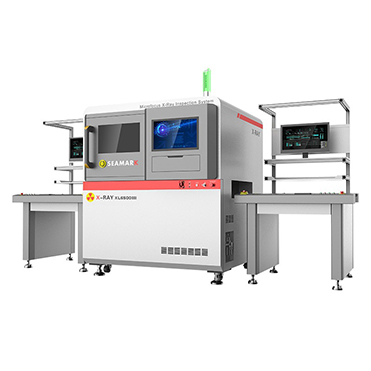

We also have types of china inline x ray machinefor sale, if you have needs, please contact us.

If you want to know more types of bga x ray machine, please visit our website.

在线联系供应商

Other supplier products

| Offline X-Ray Inspection Machine | Seamark's 2D industrial x ray inspection equipmentadopts a closed microfocus X-ray tube with voltage 90KV, 110KV,130KV, which meet different produc... | |

| ZM-R8000B Large Precision Rework Station | R8000BSurface Mount/Smd rework station boardis a large-scale precision rework station. This BGA rework system has a self-tuning temperature curve, ... | |

| Online Reel Counter | Online Reel Counter X-Ray counting machine, also known as SMD components counter. The equipment adopts the principle of photoelectric sensing and ... | |

| BGA Rework Station | We are one of the best BGA rework station machine suppliersfrom China. And now we are providing the best ball grid array rework station including ... | |

| Inline X-Ray Inspection Machine | In the inspection process of electronic components, the PCB seamark x rayinspection machine can be directly connected to the SMT production line fo... |